Light-emitting water-permeable paving material and preparation method thereof

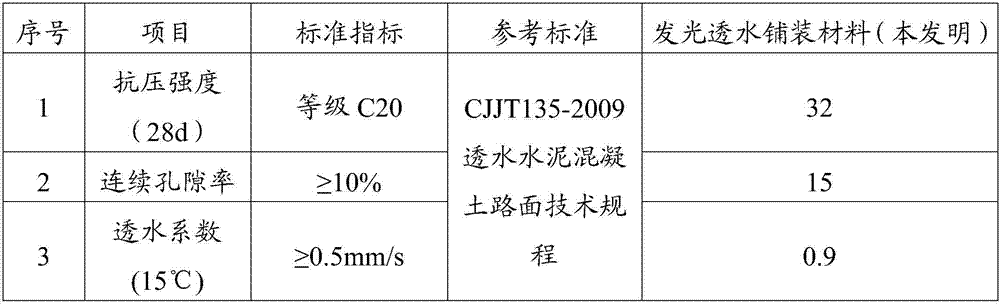

A permeable pavement and luminescence technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of insufficient night landscape decoration effect, easy fading, easy to return to alkali, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Base layer: 100 parts of P·O 42.5 cement, 450 parts of crushed stone aggregate (4.75mm-9.5mm), 30 parts of water, and 2 parts of naphthalene-based superplasticizer. Stir the cement mixture evenly before paving, tamping and smoothing.

[0024] Surface layer: 100 parts of P·O 42.5 cement, 360 parts of crushed stone aggregate (2.36-4.75mm), 36 parts of water, 1 part of red iron oxide, and 0.2 parts of naphthalene-based superplasticizer. After mixing the cement mixture evenly, pave, insert and tamp and smooth the base, and maintain it for 7 days.

[0025] Light-emitting layer: 100 parts of one-component moisture-cured polyurethane, 300 mesh yellow-green Sr 3 (BO 3 ) 2 :Mn 2+ 20 parts, gas phase SiO 2 3 parts, 10 parts of glass microspheres, 0.02 parts of PC light diffusing agent LD-105, 3 parts of xylene, 0.02 parts of silane coupling agent, mixed and stirred for 3 minutes until uniform, sprayed with a pot-type W77 spray gun, and the spray gun distance works The surfa...

Embodiment 2

[0029] Base: 100 parts of P·O 42.5 cement, 430 parts of crushed stone aggregate (4.75mm-9.5mm), 25 parts of water, 5 parts of polycarboxylate superplasticizer. Stir the cement mixture evenly before paving, tamping and smoothing.

[0030] Surface layer: 100 parts of P·O 42.5 cement, 350 parts of crushed stone aggregate (2.36-4.75mm), 36 parts of water, 1 part of chromium oxide green, 0.2 part of polycarboxylate superplasticizer. After mixing the cement mixture evenly, pave, insert and tamp and smooth the base, and maintain it for 7 days.

[0031] Light-emitting layer: 100 parts of two-component hydroxyl curable polyurethane resin, 200 mesh blue SrAl 6 o 11 :Eu 2+ , Dy 2+ 25 parts, 2 parts of organic bentonite, 5 parts of glass beads, 0.1 part of light diffusing agent XB-1500, 5 parts of toluene, 0.03 part of silane coupling agent, after mixing the above components evenly, brush with a small brush, brush The thickness is 0.2mm. The luminescent permeable pavement emits brig...

Embodiment 3

[0035] Base: 100 parts of P·O 42.5 cement, 430 parts of crushed stone aggregate (4.75mm-9.5mm), 39 parts of water, 2 parts of amino superplasticizer. Stir the cement mixture evenly before paving, tamping and smoothing.

[0036] Surface layer: 100 parts of white cement, 350 parts of crushed stone aggregate (2.36-4.75mm), 36 parts of water, 0.3 parts of amino superplasticizer. After mixing the cement mixture evenly, pave, insert and tamp and smooth the base, and maintain it for 7 days.

[0037] Light-emitting layer: 100 parts of solvent-free polyurethane, 200 mesh CaSrS:Eu 2+ , Dy 3+ 15 parts of pink luminous powder, gas phase SiO 2 2 parts, 15 parts of glass microspheres, 0.2 parts of light diffusing agent HY-690A, 3 parts of butyl acetate, 0.05 parts of silane coupling agent, mixed and stirred for 3 minutes until uniform, sprayed with a pot-mounted W77 spray gun, the distance of the spray gun The working surface is kept at about 20 cm, the air pressure is controlled at 0.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com