Preparation method and application of visible-light responsive ternary composite photocatalyst

A ternary composite, photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve undiscovered problems, achieve short reaction time, reduce energy consumption, and improve separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 NGQDs@g-C 3 N 4 / Bi 2 WO 6 Surface Composite Photocatalyst Preparation

[0029] (1) First weigh 10 g of melamine and calcinate it in a muffle furnace at a temperature of 550 ° C for 4 hours, and finally collect samples to obtain g-C 3 N 4 .

[0030] (2) 0.1653g of Na 2 WO 4 2H 2 O was dissolved in 32 mL of deionized water, followed by the addition of 0.209 g of the above-synthesized g-C 3 N 4 , after ultrasonic dispersion for 30min, add 8mL of glacial acetic acid into the above solution for mixing and stirring.

[0031] (3) Then add 0.4861g of Bi(NO 3 ) 3 ·5H 2 O was added to the above-mentioned stirred solution, and continued to stir for 1 hour to finally obtain a yellow suspension. Transfer the obtained sample to a 100mL reaction kettle, heat it in an oven at 180°C for 12 hours, and obtain a light yellow color after hydrothermal reaction. The suspension was centrifuged with distilled water and ethanol, and the product was washed several times, ...

Embodiment 2

[0033] Example 2 NGQDs@g-C 3 N 4 / Bi 2 WO 6 Characterization of Surface Composite Photocatalysis

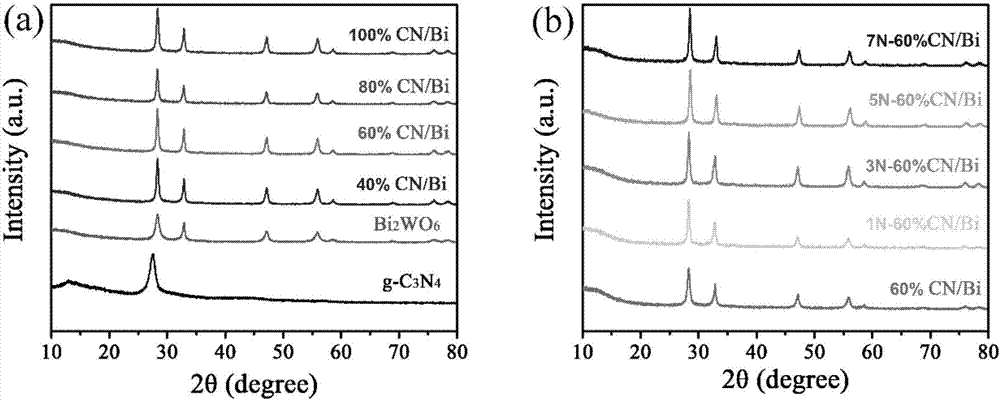

[0034] Such as figure 1 As shown, there is g-C in XRD 3 N 4 In addition to the two characteristic peaks of g-C 3 N 4 / Bi 2 WO 6 Bi in the composite photocatalyst 2 WO 6 The characteristic peaks are not due to g-C 3 N 4 changed by the addition of g-C 3 N 4 / Bi 2 WO 6 The crystallinity of the composite photocatalyst is very high. while in g-C 3 N 4 / Bi 2 WO 6 The characteristic peaks of NGQDs were not found in the composite photocatalyst because the amount of NGQDs was relatively small.

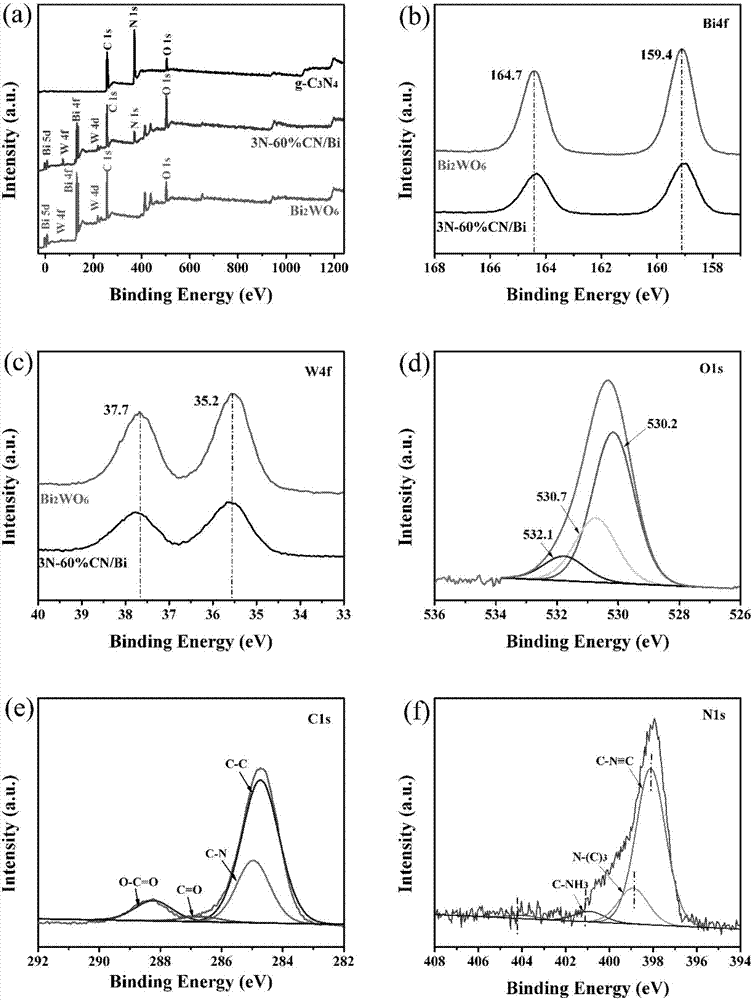

[0035] Such as figure 2 As shown in the XPS figure, it can be seen that there are C, N, O, W, and Bi elements.

Embodiment 3

[0036] Example 3 NGQDs@g-C 3 N 4 / Bi 2 WO 6 Visible light catalytic activity experiments of surface composite photocatalysts

[0037] (1) Prepare a tetracycline solution with a concentration of 10 μg / L, and place the prepared solution in a dark place.

[0038] (2) Weigh different contents of NGQDs@g-C 3 N 4 / Bi 2 WO 6 Put 50mg of composite photocatalyst on the surface into the photocatalytic reactor respectively, add 100mL of the target degradation solution prepared in step (1), and stir magnetically for 30 minutes. After the composite photocatalyst is dispersed evenly, turn on the water source and light source, and carry out the photocatalytic degradation experiment .

[0039] (3) Draw the photocatalytic degradation solution in the reactor every 10 minutes, centrifuge and use it for the measurement of ultraviolet-visible absorbance.

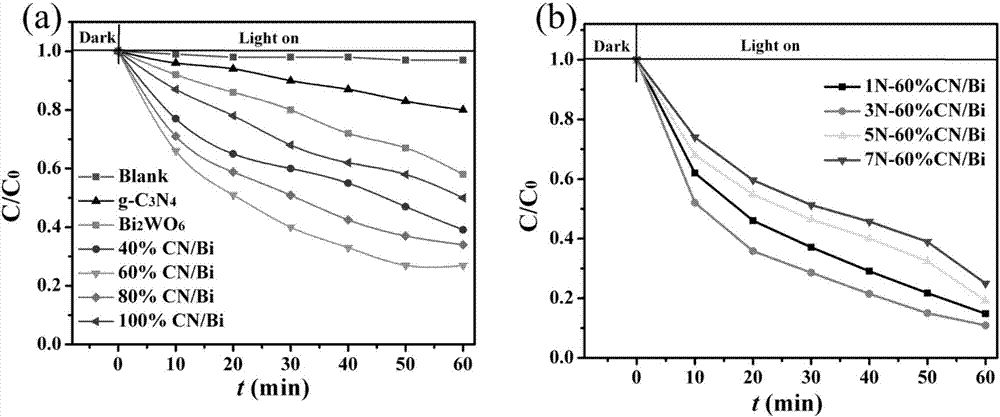

[0040] (4) by image 3 a It can be seen that in the prepared nanocomposite photocatalyst, the loading of 60% g-C 3 N 4 / Bi 2 WO 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com