Nano calcium carbonate high pressure saponification wet activation method

A nano-calcium carbonate and saponification technology, which is applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, nanotechnology, etc., can solve the problems of uneven dispersion of medicines, poor absorption of medicines, large dosage of medicines, etc., and achieve favorable The effect of particle size refinement, uniform adsorption, and lower oil absorption value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

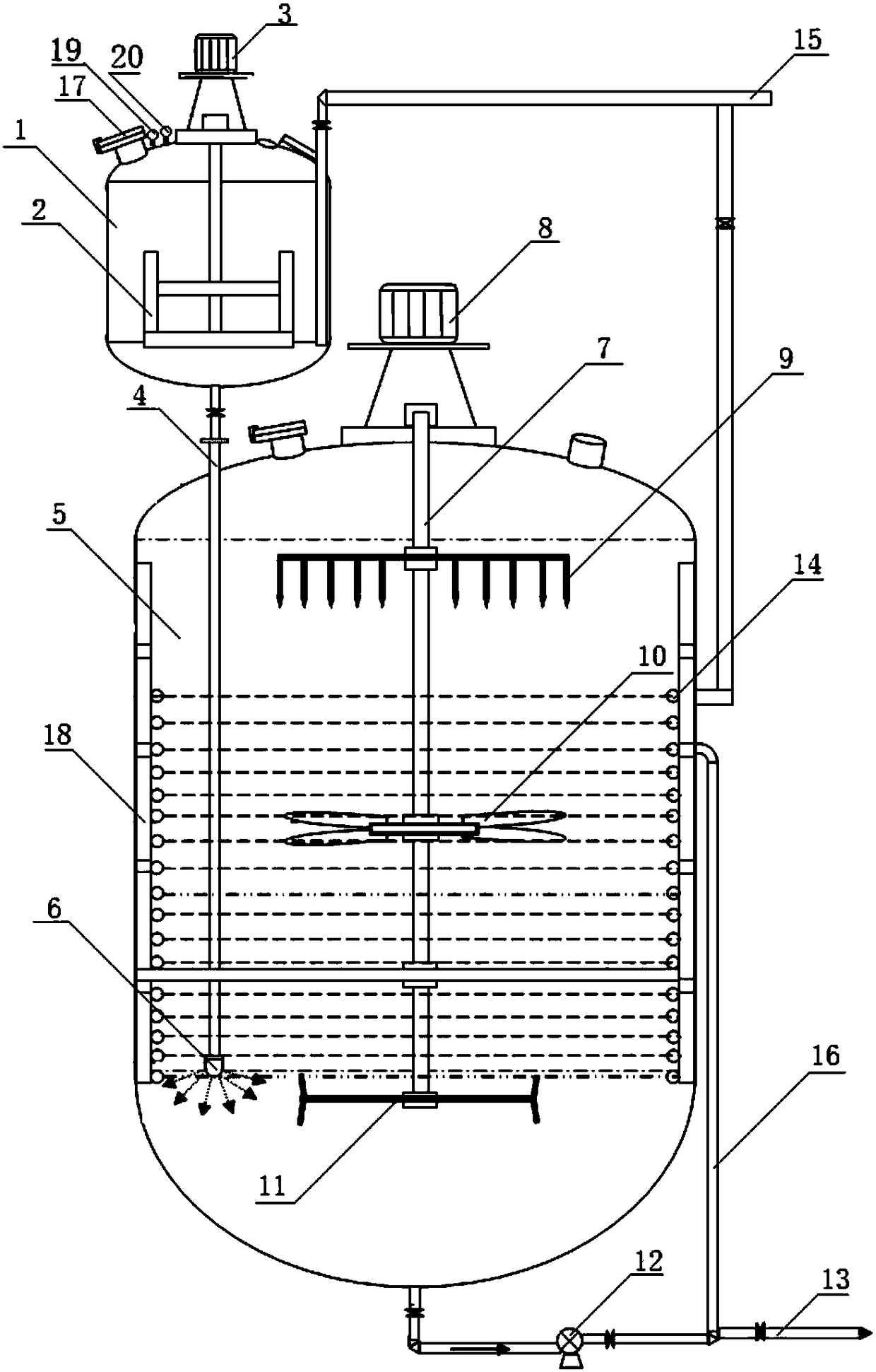

[0018] The method of nano-calcium carbonate high-pressure saponification wet activation uses the following activation device: as figure 1 As shown, it includes a saponification reactor 1, a saponification stirring device 2, a saponification discharge pipe 4, an activation kettle 5, a spiral nozzle 6, an activation stirring device, an emulsifier 12, a circulation pipe 16 and a steam heating device. The saponification stirring device 2 is arranged in the saponification reactor 1 and is connected with the motor A3. The saponification reactor 1 is provided with a feed port 17, a pressure sensor 19 and a temperature sensor 20. The bottom of the saponification reactor 1 is connected to the saponification discharge. The pipes 4 are connected; the spiral nozzle 6 and the activation stirring device are all arranged in the activation kettle 5 , the inner wall of the activation kettle 5 is provided with a baffle 18 , and the spiral nozzle 6 is connected with the saponification discharge p...

Embodiment 2

[0024] The activation device used is the same as in Example 1.

[0025] The specific operation steps are as follows:

[0026] ① Preparation of activator: Add palmitic acid, potassium hydroxide, titanate coupling agent NDZ-401 and hot water at a temperature of 85 to 95°C into the saponification reaction kettle. The weight ratio of ester coupling agent NDZ-401 and hot water is 25:4.5:10.5:425, the saponification stirring device is turned on for stirring, steam is introduced into the saponification reaction kettle, and the pressure in the reaction kettle reaches 0.45-0.5MPa , keep the pressure and continue to stir for 15 minutes to prepare the activator for subsequent use;

[0027] ② Feeding of nano-calcium carbonate: pump the cooked slurry of nano-calcium carbonate into the activation kettle, measure the concentration and volume of calcium carbonate in the activation kettle, calculate the solid content of nano-calcium carbonate, turn on the activation stirring device for contin...

Embodiment 3

[0030] The activation device used is the same as in Example 1.

[0031] The specific operation steps are as follows:

[0032] ① Preparation of activator: Add palmitic acid, potassium hydroxide, titanate coupling agent NDZ-401 and hot water at a temperature of 85 to 95°C into the saponification reaction kettle. The weight ratio of ester coupling agent NDZ-401 and hot water is 25:4:10:400, the saponification stirring device is turned on for stirring, steam is passed into the saponification reaction kettle, and the pressure in the reaction kettle reaches 0.45-0.5MPa , keep the pressure and continue to stir for 13 minutes to prepare the activator for subsequent use;

[0033]② Feeding of nano-calcium carbonate: pump the cooked slurry of nano-calcium carbonate into the activation kettle, measure the concentration and volume of calcium carbonate in the activation kettle, calculate the solid content of nano-calcium carbonate, turn on the activation stirring device for continuous stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com