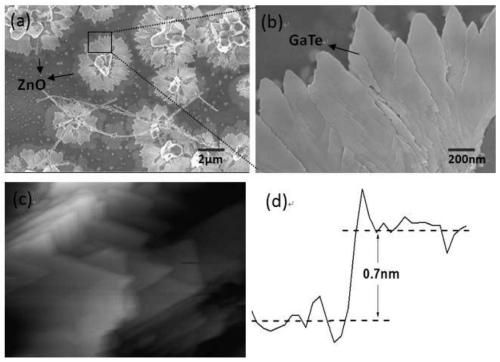

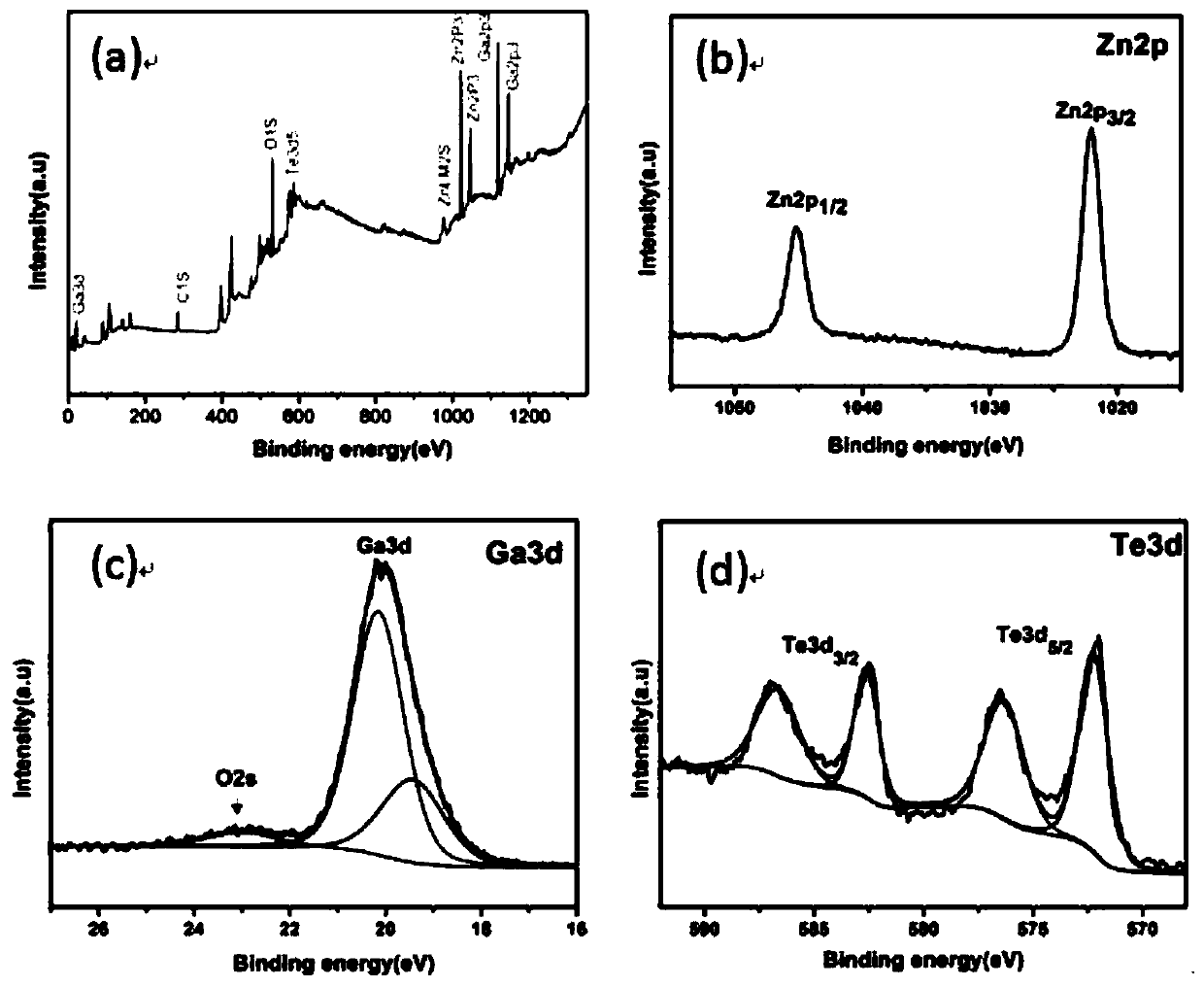

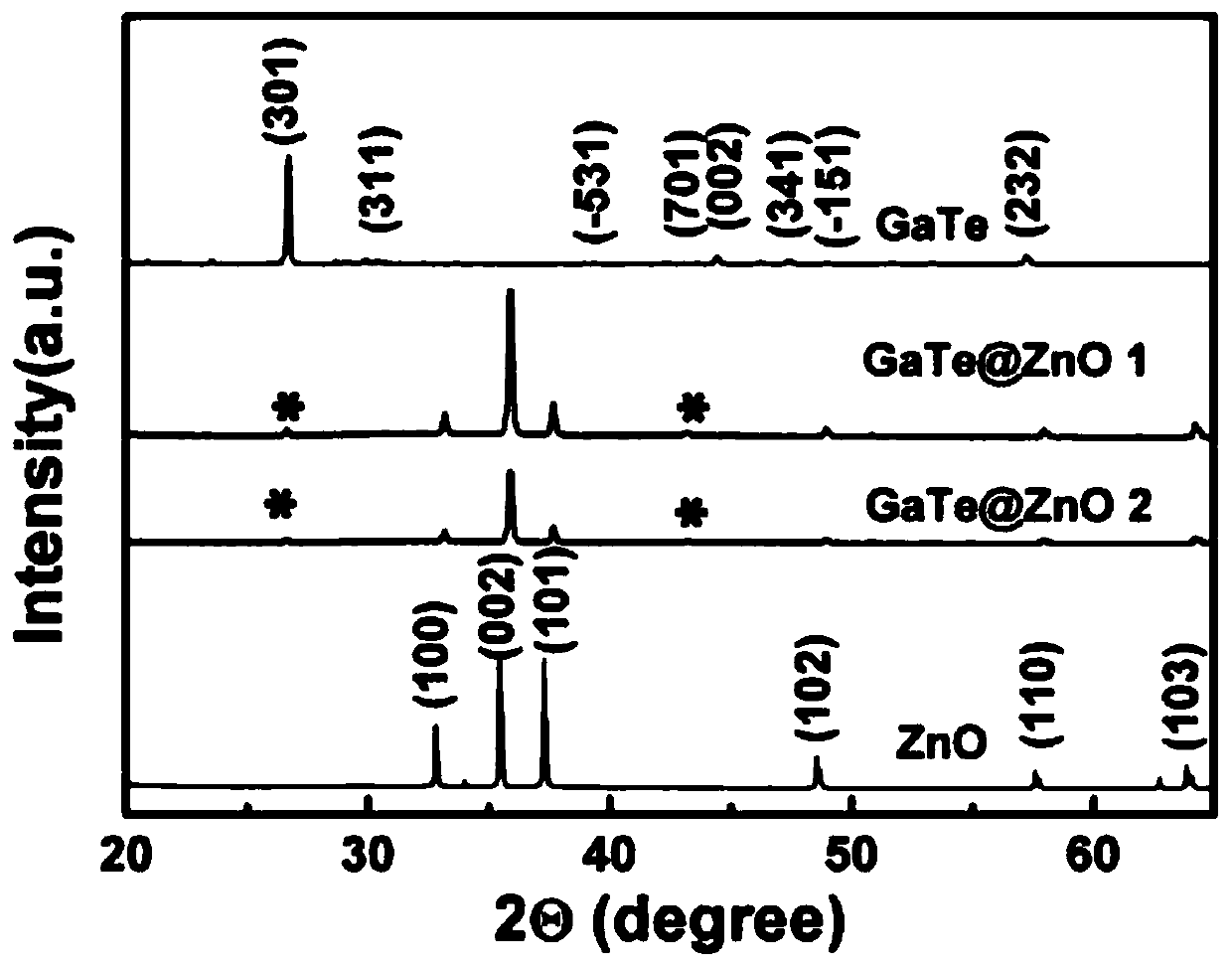

A controllable preparation method for self-assembled nanoflowers of p-type layered GaTe nanosheets

A technology of nanoflowers and gallium telluride, applied in chemical instruments and methods, selenium/tellurium compounds, metal selenides/tellurides, etc., can solve the problems of difficult and controllable preparation of GaTe nanomaterials, and achieve obvious pn junction rectification effect , Overcoming the effect of easy recombination and good photoelectrocatalytic hydrogen production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for the controllable preparation of large-area p-type layered GaTe nanosheet self-assembled nanoflowers under normal pressure, comprising the steps of:

[0037] The first step is to clean the sapphire wafer and quartz boat. First, put a sapphire substrate with a size of 1×1cm, a thickness of 0.5mm, and a surface roughness of 0.2nm into a beaker filled with 50ml of ethanol, perform ultrasonic cleaning for 15 minutes, and take it out and blow it dry with a nitrogen gun; Next, put the dried sapphire substrate into another beaker containing 50 ml of acetone, perform ultrasonic cleaning for 15 minutes, take it out and dry it with a nitrogen gun; finally put the dried sapphire substrate into 100 ml of deionized In water, perform ultrasonic cleaning for 10 minutes, take it out and dry it with a nitrogen gun.

[0038] In the second step, the sapphire substrate is annealed. The sapphire substrate cleaned up in the first step is directly put into the double-temperatur...

Embodiment 2

[0049] A method for the controllable preparation of large-area p-type layered GaTe nanosheet self-assembled nanoflowers under normal pressure, comprising the steps of:

[0050] The first step is to clean the sapphire wafer and quartz boat. First, put a sapphire substrate with a size of 1×1cm, a thickness of 0.5mm, and a surface roughness of 0.2nm into a beaker filled with 50ml of ethanol, perform ultrasonic cleaning for 15 minutes, and take it out and blow it dry with a nitrogen gun; Next, put the dried sapphire substrate into another beaker containing 50 ml of acetone, perform ultrasonic cleaning for 15 minutes, take it out and dry it with a nitrogen gun; finally put the dried sapphire substrate into 100 ml of deionized In water, perform ultrasonic cleaning for 10 minutes, take it out and dry it with a nitrogen gun.

[0051] In the second step, the sapphire substrate is annealed. The sapphire substrate cleaned up in the first step is directly put into the double-temperatur...

Embodiment 3

[0058] A method for the controllable preparation of large-area p-type layered GaTe nanosheet self-assembled nanoflowers under normal pressure, comprising the steps of:

[0059] The first step is to clean the sapphire wafer and quartz boat. First, put a sapphire substrate with a size of 1×1cm, a thickness of 0.5mm, and a surface roughness of 0.2nm into a beaker filled with 50ml of ethanol, perform ultrasonic cleaning for 15 minutes, and take it out and blow it dry with a nitrogen gun; Next, put the dried sapphire substrate into another beaker containing 50 ml of acetone, perform ultrasonic cleaning for 15 minutes, take it out and dry it with a nitrogen gun; finally put the dried sapphire substrate into 100 ml of deionized In water, perform ultrasonic cleaning for 10 minutes, take it out and dry it with a nitrogen gun.

[0060] In the second step, the sapphire substrate is annealed. The sapphire substrate cleaned up in the first step is directly put into the double-temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com