Method for separating and refining 1, 2, 4-butantriol from microbial fermentation liquid

A refining method, butanetriol technology, applied in the fields of bioengineering and chemical engineering, can solve the problems of low efficiency, slow speed, complex components of fermentation products, etc., and achieve the effect of high separation efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

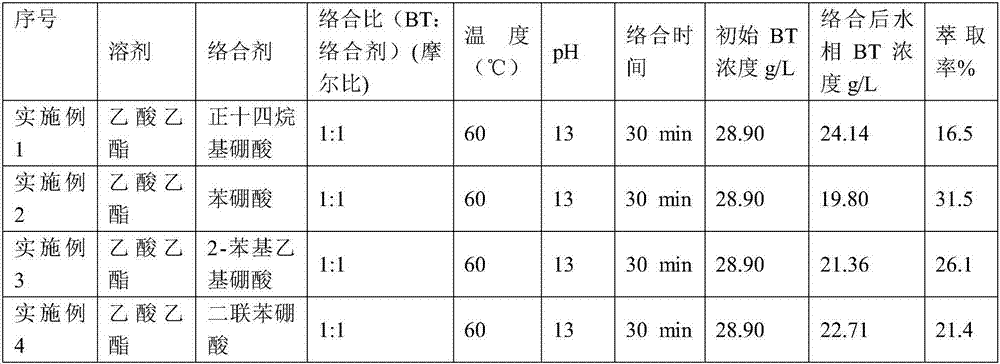

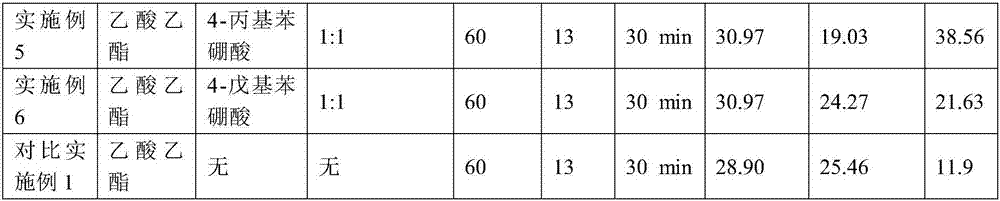

Examples

Embodiment 1

[0024] The BT fermented liquid in which the BT concentration is about 3-6 g / L is heat-sterilized and plate-and-frame filtered to remove bacteria and flocculated solid protein in the fermented liquid.

[0025] Add the ethyl acetate solution of n-tetradecylboronic acid to the fermented broth that removes the thalline after filtration, the total volume ratio of ethyl acetate and aqueous solution is about 1:1, make described n-tetradecylboronic acid and fermented broth The molar ratio of BT is controlled at about 1:1, forming two phases with aqueous solution. Among them, under the condition of 60°C, add 0.46g of n-tetradecylboronic acid complexing agent into 10ml of ethyl acetate, stir and dissolve, add 10ml of 0.1mol / L sodium hydroxide solution, and adjust the pH value to about 13 , then add 10ml of BT fermentation broth, stir slowly moderately, and use the complexation between the boric acid reagent in the organic phase and the BT in the fermentation broth to perform selective c...

Embodiment 2

[0028] The concentration of BT in the BT fermentation liquid is about 3-6g / L, and the fermentation liquid is sterilized by heat and filtered by plate and frame to remove the bacteria and flocculated solid protein in the fermentation liquid.

[0029] Add ethyl acetate solution of phenylboronic acid to the fermented broth after filtering to remove the bacteria, the total volume ratio of ethyl acetate to aqueous solution is about 1:1, so that the molar ratio of BT in the phenylboronic acid to the fermented broth is controlled At about 1:1, form two phases with the aqueous solution, moderately and slowly stir, use the complexation between the boric acid reagent in the organic phase and the BT in the fermentation broth to perform selective complexation extraction, after stirring for 30min, to the fermentation broth The concentration of BT in the medium is less than 0.5g / L, separate the aqueous phase and the organic solvent phase, and repeat this 3 times, each time using the same amo...

Embodiment 3

[0032] The BT product was obtained in the same manner as in Example 1 except that 2-phenylethylboronic acid was used as the organic boric acid.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap