Preparation method of magnetic/gold nano composite particle

A technology of composite particles and gold nanometers, applied in nanotechnology, metal processing equipment, coatings, etc., can solve problems such as cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Add 10 ml of ethylene glycol to a three-necked flask, weigh 0.08 g of polyglutamic acid and add it to fully dissolve; add 0.27 g of polyethyleneimine with a molecular weight of 25000 to another 3 ml of ethylene glycol and sonicate until it is completely dissolved; Add 0.65 g FeCl to 20 ml ethylene glycol 3 • 6H 2 O and 1.65 g NH 4 After OAc is sonicated until it is completely dissolved and uniformly dispersed, mix the above three ethylene glycol solutions and continue to ultrasonically disperse uniformly;

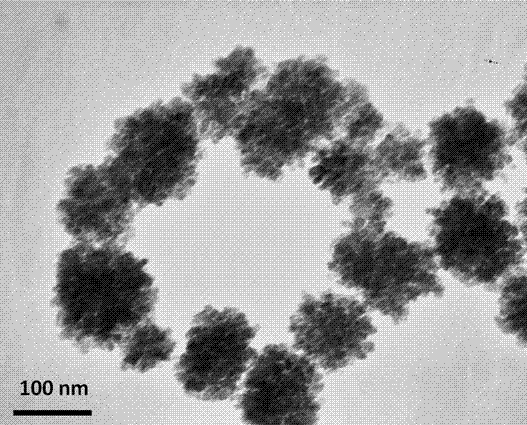

[0019] (2). Place the three-necked flask containing the glycol solution in step (1) in an electric heating mantle set to 160 ℃ and continue to heat and stir for 15 minutes. The mixed solution was transferred to a stainless steel reactor with a polytetrafluoroethylene liner, heated at 200 ℃ for 12 hours, and the product was washed three times with ethanol and deionized water; a 50 mL reactor can obtain 80-100 mg of magnetic material in one reaction. The average parti...

Embodiment 2

[0022] (1) Add 10 ml of ethylene glycol to the three-necked flask, weigh 0.09 g of hyaluronic acid and add it to fully dissolve; add 0.27 g of polyethyleneimine with a molecular weight of 600 to the other 3 ml of ethylene glycol and sonicate until it is completely dissolved; Add 0.65 g FeCl to 20 ml ethylene glycol 3 • 6H 2 O and 1.65 g NH 4 After OAc is sonicated until it is completely dissolved and uniformly dispersed, mix the above three ethylene glycol solutions and continue to ultrasonically disperse uniformly;

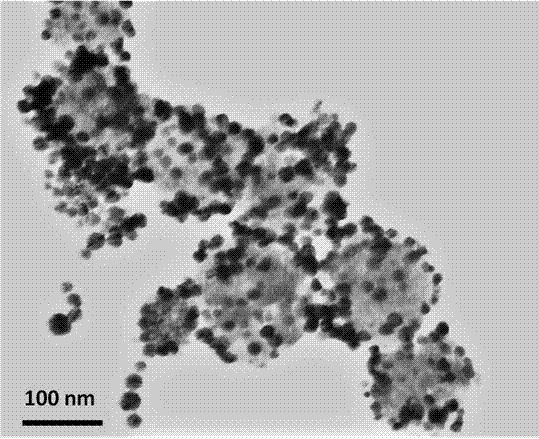

[0023] (2). Place the three-necked flask containing the glycol solution in step (1) in an electric heating mantle set to 160 ℃ and continue to heat and stir for 15 minutes. The mixed solution was transferred to a stainless steel reactor with a polytetrafluoroethylene liner, heated at 200 ℃ for 15 hours, and the product was washed three times with ethanol and deionized water; a 50-mL reactor can obtain 50-80 mg of magnetic material in one reaction. The average parti...

Embodiment 3

[0026] (1) Add 10 ml of ethylene glycol into the three-necked flask, weigh 0.08 g of chitosan and add it to fully dissolve it; add 0.27 g of polyethyleneimine with a molecular weight of 25000 to the other 3 ml of ethylene glycol until it is completely dissolved; Add 0.65 g FeCl to ml ethylene glycol 3 • 6H 2 O and 1.65 g NH 4 After OAc is sonicated until it is completely dissolved and uniformly dispersed, mix the above three ethylene glycol solutions and continue to ultrasonically disperse uniformly;

[0027] (2). Place the three-necked flask containing the glycol solution in step (1) in an electric heating mantle set to 160 ℃ and continue to heat and stir for 15 minutes. The mixed solution was transferred to a stainless steel reactor with a polytetrafluoroethylene liner, heated at 200 ℃ for 12 hours, and the product was washed three times with ethanol and deionized water; a 50 mL reactor can obtain 80-100 mg of magnetic material in one reaction. The average particle size is 180...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com