Biological feed and preparation method thereof

A technology of biological feed and weight, which is applied in the direction of animal feed, animal feed, additional food elements, etc., can solve the problems of high production cost of enzymatic fermentation and fermentation, and achieve the effects of ensuring the safety of pork food, improving the nutritional level, and improving the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

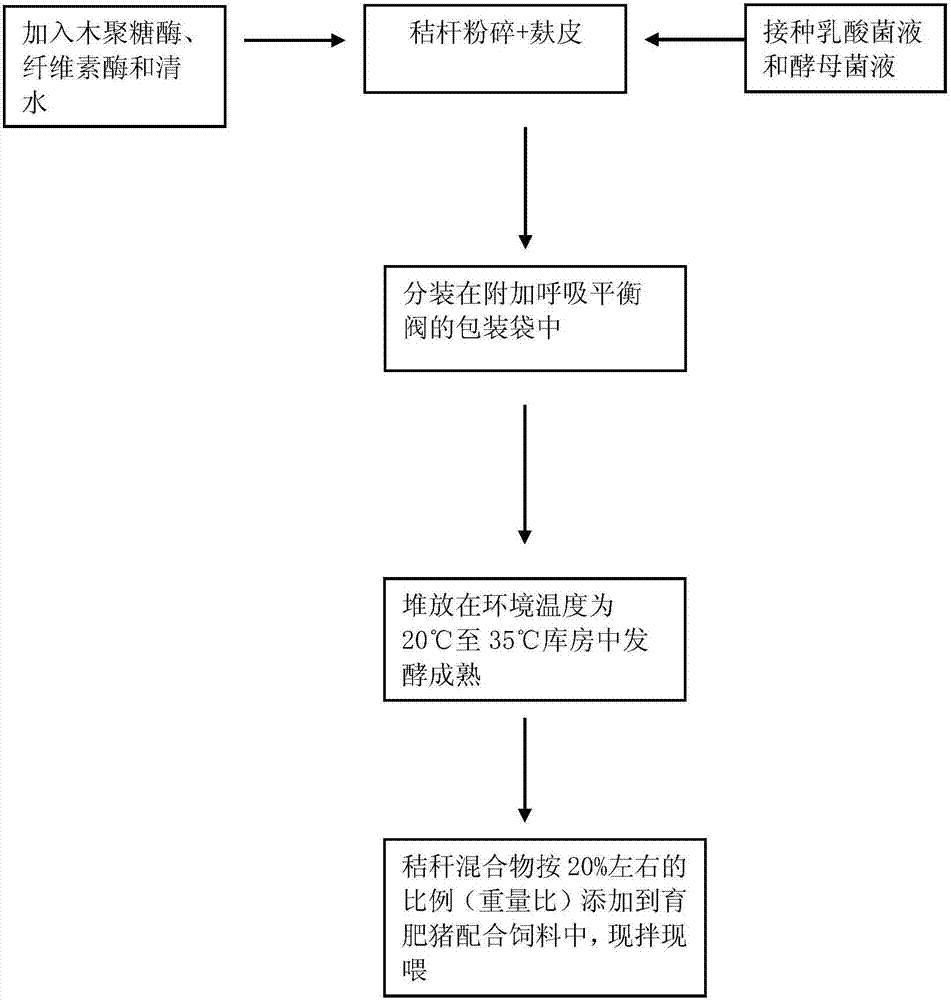

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Crush the stalks, the length of which should not exceed 5mm.

[0033] The second step: add wheat bran accounting for about 5% of the weight of the straw to the straw powder.

[0034] Step 3: Add 0.02% xylanase (50,000 IU / g) and 0.01% cellulase (20,000 IU / g) to the mixture of straw and wheat bran.

[0035] Step 4: adding clear water to the mixture with the enzyme added, injecting clear water into the mixture according to 80% of the straw weight, and fully mixing.

[0036] Step 5: Inoculate the lactic acid bacteria liquid and yeast liquid into the mixture that has been injected with clean water. The inoculation proportion of the lactic acid bacteria liquid accounts for about 2% of the straw weight; the inoculation proportion of the yeast liquid accounts for about 0.5% of the straw weight.

[0037] Step 6: Pack the mixed and inoculated materials into packaging bags with additional breathing balance valves, seal them tightly, and stack them in a warehouse with an ...

Embodiment 2

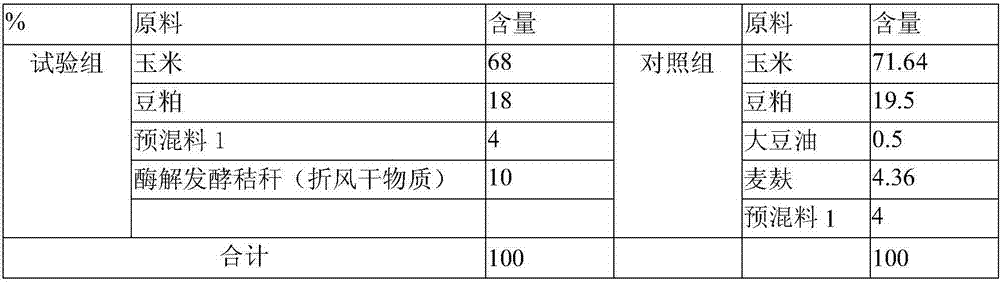

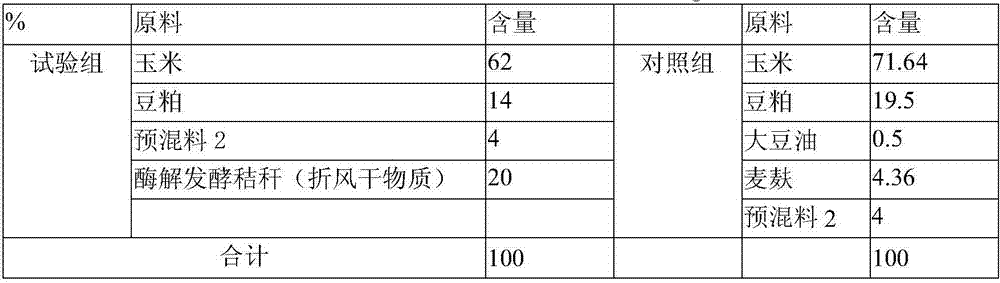

[0042]Select binary hybrid pigs (long × large) of about 40kg, and divide them into 2 treatments according to random block design, each treatment has 6 repetitions (columns), and each repetition has 6 pigs. A total of 12 pens were used in the experiment. The test is divided into two stages: 40-60kg and 60-90kg body weight stage feeding. The experimental group was fed a compound diet containing fermented straw, and the control group was fed a conventional diet containing antibiotics. The test results showed that there was no significant difference in average daily gain, daily feed intake and feed / weight gain ratio between the experimental group and the control group in the first stage (P>0.05). The average daily gain increased by 3.1%; the average daily gain, daily feed intake and feed / weight gain ratio of the second stage between the test group and the control group did not show significant differences (P>0.05). The average daily gain of the enzymatically hydrolyzed and ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com