A silk fibroin/gelatin stent material based on three-dimensional printing and a preparing method thereof

A fibroin, three-dimensional printing technology, applied in the fields of additive processing, medical science, prosthesis, etc., can solve the problems of biocompatibility and green degradable properties of scaffold materials, increase process difficulty and material cost, etc., and achieve excellent Biocompatibility and bioactivity, good effect of biocompatibility and bioactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

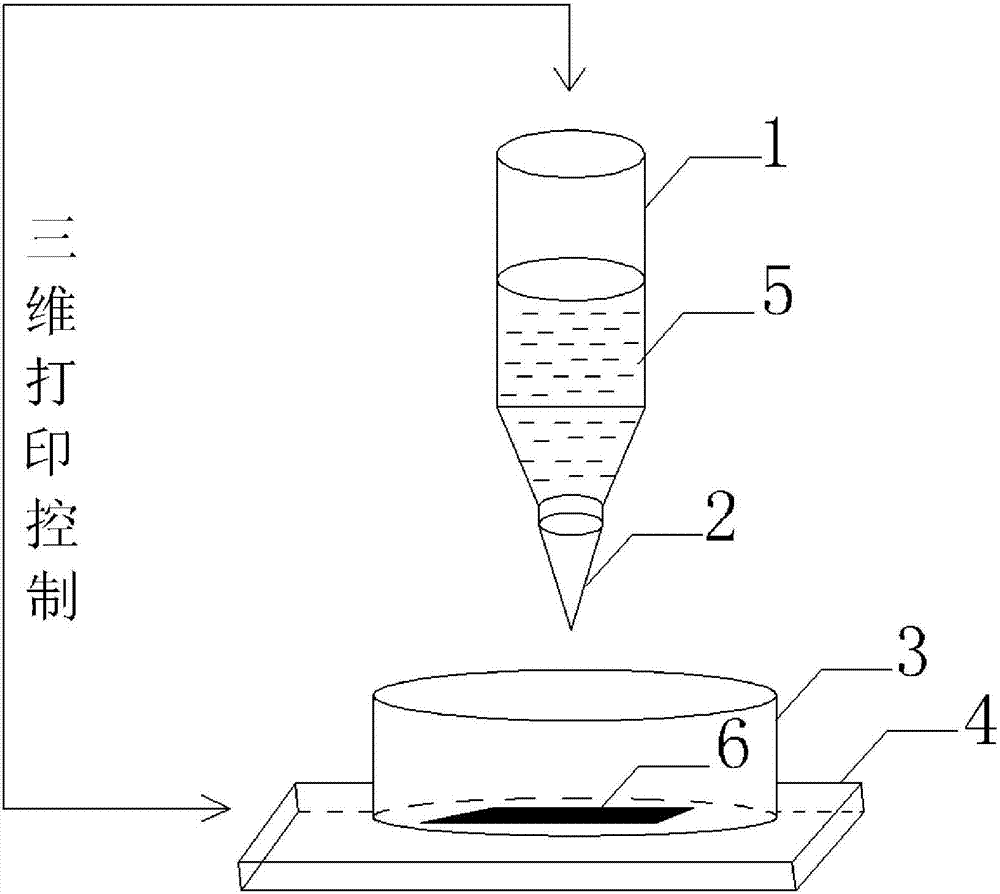

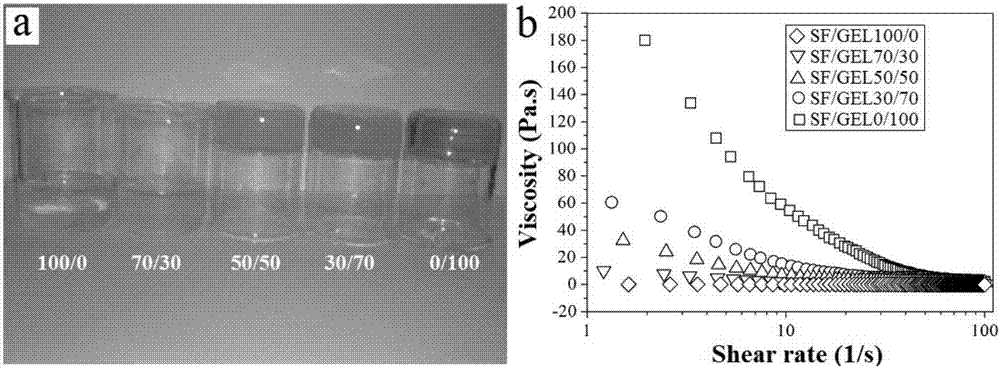

[0038] (1) Add the degummed silk fibers into the calcium chloride-ethanol-water ternary solution with a molar ratio of 1:2:8, heat and stir at 70°C until completely dissolved, filter, dialyze and concentrate to obtain a mass fraction of 3% fibroin solution, add gelatin to the fibroin solution, mix evenly to form a fibroin / gelatin composite hydrogel, wherein the mass ratio of the fibroin solution to the gelatin in the fibroin / gelatin mixed solution is 100:0.

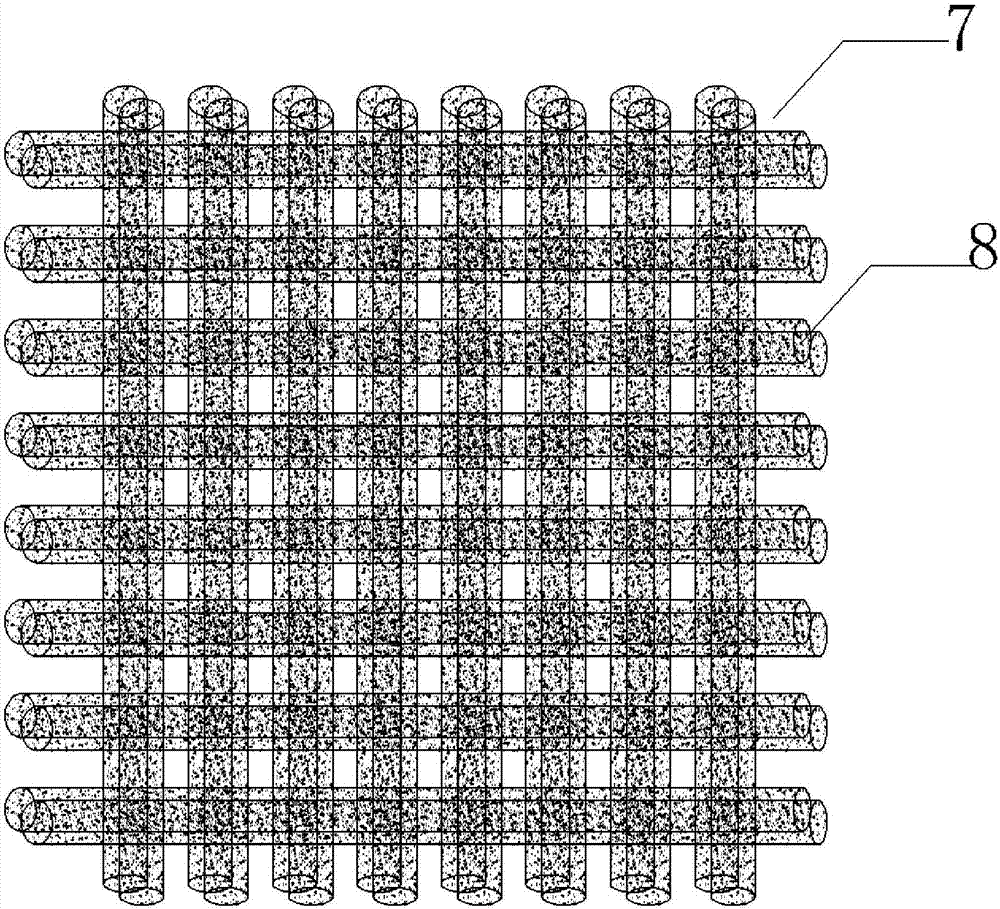

[0039] (2) In the MIMICS software, a scaffold model with a cyclic cross network structure was established, and a polystyrene petri dish was used as a scaffold receiving device. The fibroin / gelatin composite hydrogel was placed in the syringe of the 3D printer, and the needle was adjusted. The distance between the needle in the cylinder and the receiving device is 0.5mm, place the receiving device on the temperature control device, adjust the temperature of the temperature control device to 4°C, and set it aside.

[0040] ...

Embodiment 2

[0043] (1) Add the degummed silk fibers into the calcium chloride-ethanol-water ternary solution with a molar ratio of 1:2:8, heat and stir at 80°C until completely dissolved, filter, dialyze and concentrate to obtain a mass fraction of 8% fibroin solution, add gelatin to the fibroin solution, mix evenly to form a fibroin / gelatin composite hydrogel, wherein the mass ratio of the fibroin solution to the gelatin in the fibroin / gelatin mixed solution is 70:30.

[0044] (2) In the MIMICS software, a scaffold model with a cyclic cross network structure was established, and a polystyrene petri dish was used as a scaffold receiving device. The fibroin / gelatin composite hydrogel was placed in the syringe of the 3D printer, and the needle was adjusted. The distance between the needle in the cylinder and the receiving device is 0.5mm, place the receiving device on the temperature control device, adjust the temperature of the temperature control device to 4°C, and set it aside.

[0045] ...

Embodiment 3

[0048] (1) Add the degummed silk fibers into the calcium chloride-ethanol-water ternary solution with a molar ratio of 1:2:8, heat and stir at 75°C until completely dissolved, filter, dialyze and concentrate to obtain a mass fraction of 5% fibroin solution, add gelatin to the fibroin solution, mix evenly to form a fibroin / gelatin composite hydrogel, wherein the mass ratio of the fibroin solution to the gelatin in the fibroin / gelatin mixed solution is 50:50.

[0049] (2) In the MIMICS software, a scaffold model with a cyclic cross network structure was established, and a polystyrene petri dish was used as a scaffold receiving device. The fibroin / gelatin composite hydrogel was placed in the syringe of the 3D printer, and the needle was adjusted. The distance between the needle in the cylinder and the receiving device is 0.5mm, place the receiving device on the temperature control device, adjust the temperature of the temperature control device to 4°C, and set it aside.

[0050] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com