Cadmium sulfide nanoflower, preparation thereof and application thereof

A technology of cadmium sulfide and nanoflowers, applied in cadmium sulfide, nanotechnology, inorganic chemistry, etc., can solve the problems of poor dispersion of nanoparticles, easy agglomeration, and small specific surface area, and achieve low equipment loss, good repeatability, and excellent production. The effect of hydrogen performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Preparation of Cadmium Sulfide Nanoflowers by Mixed Solvothermal Method of Diethylenetriamine and Ethanol (2∶1)

[0049] Measure 40ml of diethylenetriamine (DETA) and 20ml of ethanol, mix and stir, weigh 2mmol of Cd(AC) 2 2H 2 O and 10 mmol of thiourea were added to the mixed solution and stirred for 30 min until clarification. Transfer to a polytetrafluoroethylene reaction kettle with a volume of 80ml, cover and seal it, put it into a stainless steel sleeve and lock it, place it in a blast drying oven and heat it up to 80°C, keep it warm for 48h, and then cool it down to room temperature naturally. The obtained precipitate was washed once with ethanol solution and twice with deionized water, put into the refrigerator for pre-freezing for 12 hours, and then freeze-dried in a freeze dryer at -60°C for 12 hours under vacuum to obtain a light yellow powder.

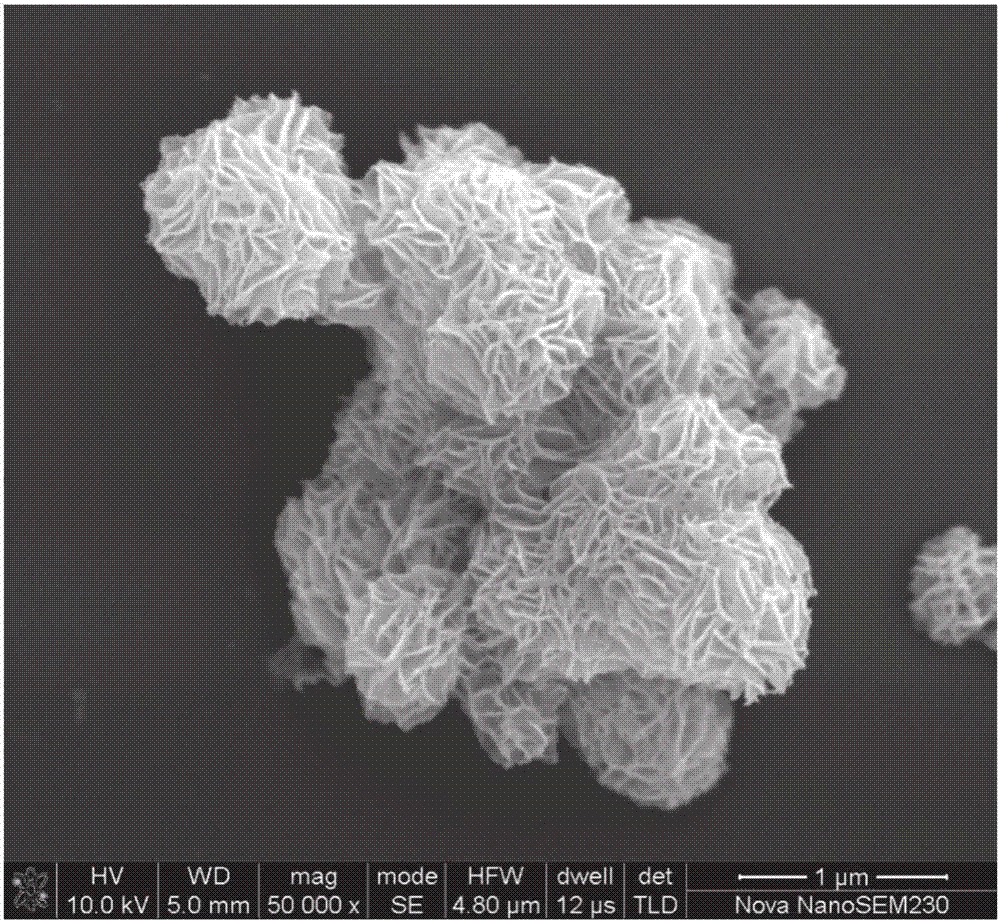

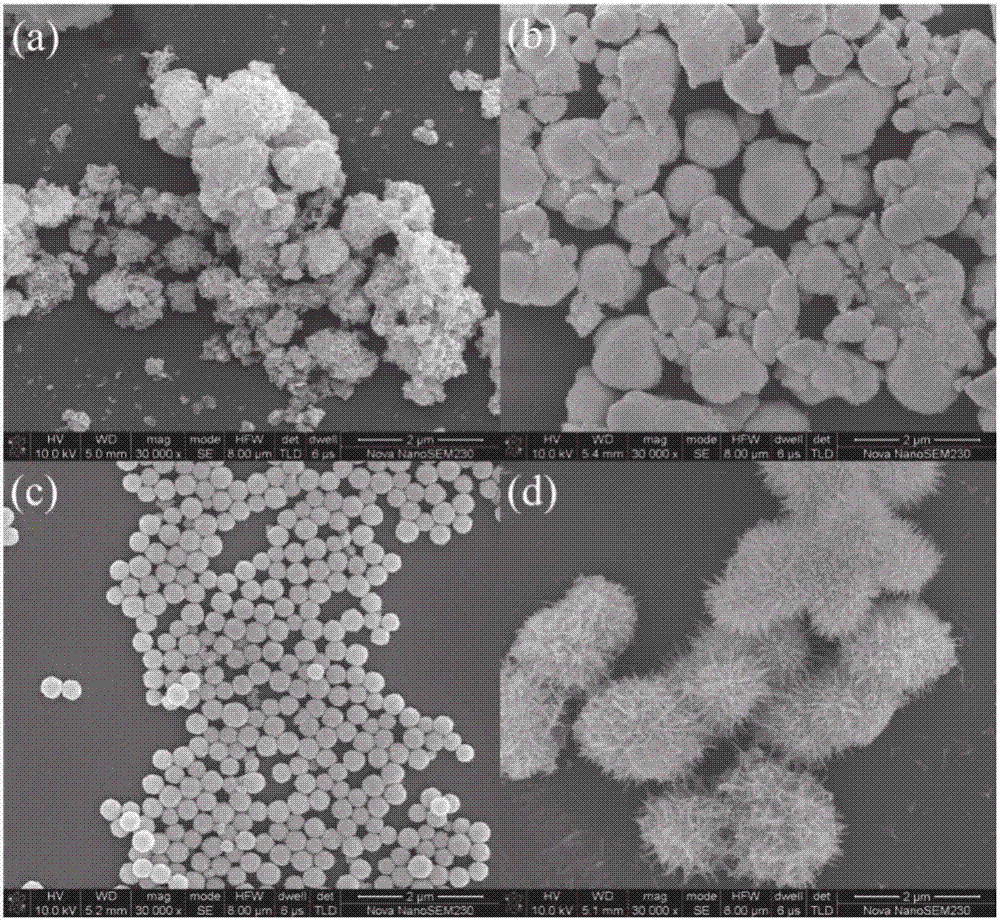

[0050] The SEM figure of the material that this embodiment makes is shown in figure 1, the appearance of cadmium...

Embodiment 2

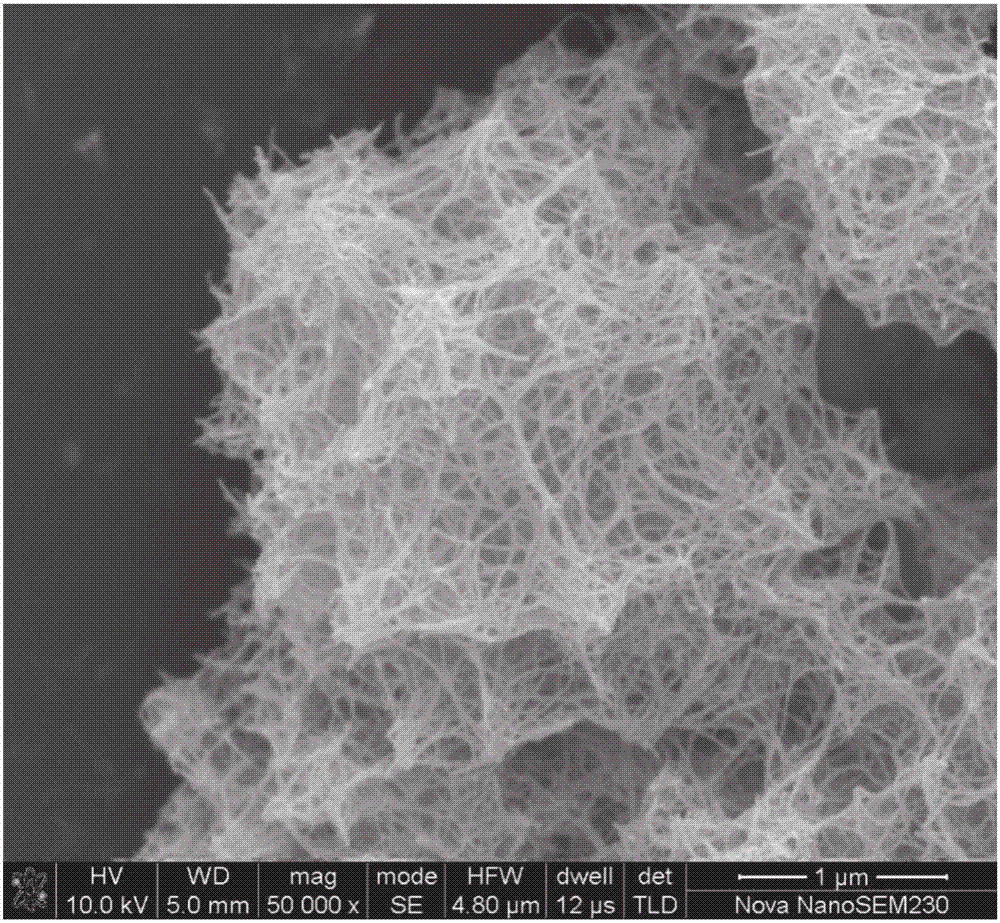

[0052] Compared with Example 1, the only difference is that the ratio of diethylenetriamine (DETA) and ethanol is 1:5, the total amount of mixed solvent and other parameters are equal to Example 1. The prepared cadmium sulfide has a flower-like appearance, a size of 200nm-2μm, and a specific surface area of 92.36m2 / g. The hydrogen production rate is 1.34mmol·h -1 g -1 .

Embodiment 3

[0054] Compared with Example 1, the only difference is that the ratio of diethylenetriamine (DETA) and ethanol is 5:1, the total amount of mixed solvent and other parameters are equal to Example 1. The prepared cadmium sulfide has a flower-like appearance, a size of 200nm-2μm, and a specific surface area of 65.33m2 / g. The hydrogen production rate is 2.53mmol·h -1 g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com