Composition for controlling contamination of boiler or other components and application thereof

A composition and boiler technology, applied in the direction of combustion product treatment, non-flammable liquid/gas transportation, combustion method, etc., can solve the problem of not reaching the rated load, restricting the use of Zhundong coal, and strong pollution of the heat exchange surface, etc. problems, to ensure safe and reliable operation, and to solve serious coking and pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of the composition

[0033] Siliceous materials and oxides of alkaline earth metals (wherein the silicate materials are magnesium silicate, sodium metasilicate, microsilica, white carbon black, etc.; alkaline earth metal oxides are magnesium oxide, barium oxide or calcium oxide) with a certain The ratio (silicon material: alkaline earth metal oxide = 0.25 ~ 1:3) is put into a mixer (twin-shaft screw mixer) and mixed evenly, and then the resulting mixture is put into a grinder (Raymond mill) to grind to fineness It can be 150-600 mesh. Subsequently, 100 to 1500 ppm of rare earth oxide (cerium nitrate or cerium oxide) is added to the above mill based on the total weight of the composition, thereby obtaining a composition.

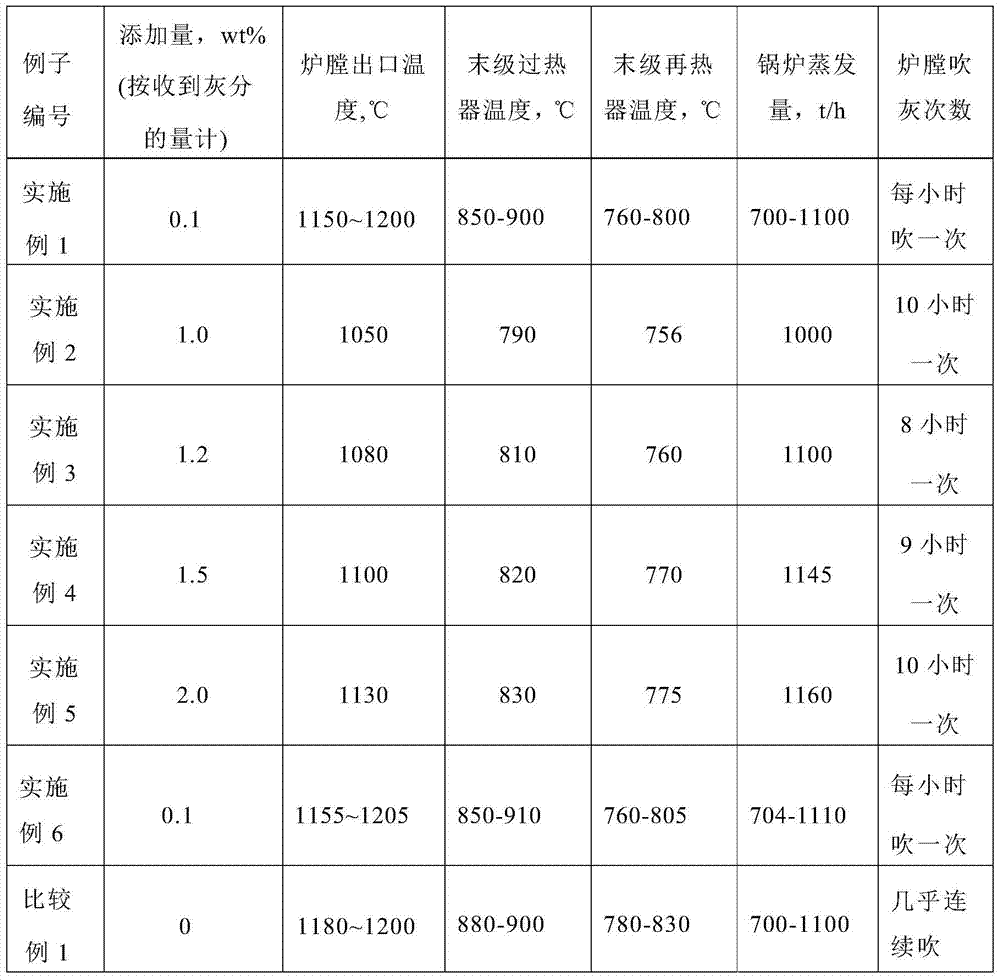

[0034] Calculated based on the amount of ash received, continuously spray 0.1% by weight composition into the convective heat exchange area upstream of the flue gas of a 350MW supercritical boiler, and then measure the furnace outlet tempe...

Embodiment 2

[0036] The composition in Example 1 is continuously sprayed into the convective heat exchange area upstream of the flue gas of the 350MW supercritical boiler, the difference is: based on the calculation of the amount of ash received, the content of the injected composition is 1.0 wt. %. Then measure the furnace outlet temperature, final superheater temperature, final reheater temperature, boiler evaporation and furnace soot blowing times. Wherein the above results are the results of adding the composition for one week. The test results are summarized in Table 1.

Embodiment 3

[0038] The composition in Example 1 is continuously sprayed into the convective heat exchange area upstream of the flue gas of the 350MW supercritical boiler, the difference is: based on the calculation of the amount of ash received, the content of the injected composition is 1.2 wt. %. Then measure the furnace outlet temperature, final superheater temperature, final reheater temperature, boiler evaporation and furnace soot blowing times. Wherein the above results are the results of adding the composition for one week. The test results are summarized in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com