Processing method of green tea

A processing method and technology of green tea, which is applied in the field of tea processing, can solve the problems of bitterness and astringency of tea soup, and achieve the effect of reducing the taste of grass and facilitating rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

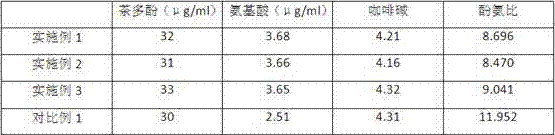

Examples

Embodiment 1

[0019] A kind of processing method of green tea is characterized in that, comprises the following steps:

[0020] Step 1. Material selection: select tea leaves with a single bud or one bud and one leaf;

[0021] Step 2. Drying: Use microwave vacuum drying technology to dry the picked tea leaves to a moisture content of 45%, a vacuum degree of 0.1Mpa, and a microwave power of 1.5kw;

[0022] Step 3, kneading: Spray the coconut juice evenly on the surface of the dried tea leaves, then put the tea leaves into the kneading machine for kneading. When kneading, knead the tea leaves for 5 minutes in a heavy kneading method, and then spray the tea leaves for the second time Coconut juice, after the coconut juice is sprayed for the second time, knead the tea leaves for 9 minutes in a light kneading manner, wherein the light kneading pressure is 200N, the rotating speed is 10r / min, the heavy kneading pressure is 550N, and the rotating speed is 25r / min;

[0023] Step 4, drying: use micr...

Embodiment 2

[0026] A kind of processing method of green tea is characterized in that, comprises the following steps:

[0027] Step 1. Material selection: select tea leaves with a single bud or one bud and one leaf;

[0028] Step 2. Drying: Use microwave vacuum drying technology to dry the picked tea leaves to a moisture content of 48%, a vacuum degree of 0.085Mpa, and a microwave power of 2kw;

[0029] Step 3. Kneading: Spray the coconut juice evenly on the surface of the dried tea leaves, and then put the tea leaves into the kneading machine for kneading. When kneading, knead the tea leaves for 4 minutes in a heavy kneading method, and then spray them on the surface of the tea leaves for the second time Coconut juice, after the coconut juice is sprayed for the second time, knead the tea leaves for 10 minutes in a light kneading manner, wherein the light kneading pressure is 300N, the rotating speed is 15r / min, the heavy kneading pressure is 600N, and the rotating speed is 20r / min;

[00...

Embodiment 3

[0033] A kind of processing method of green tea is characterized in that, comprises the following steps:

[0034] Step 1. Material selection: select tea leaves with a single bud or one bud and one leaf;

[0035] Step 2. Drying: Use microwave vacuum drying technology to dry the picked tea leaves to a moisture content of 46%, a vacuum degree of 0.09Mpa, and a microwave power of 1kw;

[0036] Step 3. Kneading: Spray the coconut juice evenly on the surface of the dried tea leaves, and then put the tea leaves into the kneading machine for kneading. When kneading, knead the tea leaves for 5 minutes by heavy kneading, and then spray the tea leaves for the second time Coconut juice, after the coconut juice is sprayed for the second time, knead the tea leaves for 8 minutes in a light kneading manner, wherein the light kneading pressure is 250N, the rotating speed is 13r / min, the heavy kneading pressure is 500N, and the rotating speed is 30r / min;

[0037] Step 4, drying: microwave dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com