Magnesium silicate-hydrothermal carbon composite material and its preparation method and application

A composite material, magnesium silicate technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems of limited adsorption capacity and poor adsorption effect, and achieve increased specific surface area and effective adsorption site, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

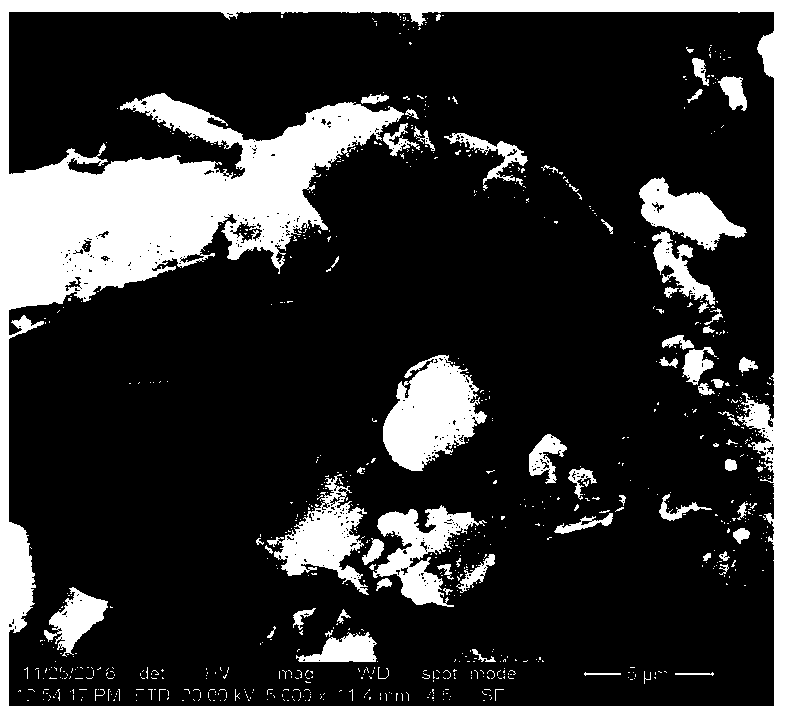

[0036] A magnesium silicate-hydrothermal carbon composite material of the present invention is in the form of black-gray powder macroscopically, including massive porous magnesium silicate and spherical hydrothermal carbon, and the hydrothermal carbon is supported on the surface and pores of the magnesium silicate. , and chemically combined with magnesium silicate. Among them, the particle size of the hydrothermal carbon is 500-1000 nm, and the loading of the hydrothermal carbon is 37% of the mass of the magnesium silicate-hydrothermal carbon composite material. The magnesium silicate-hydrothermal carbon composite material is environmentally friendly, non-toxic, and low in cost. It is not easy to agglomerate, and has a strong adsorption effect on cationic dyes and heavy metals in water.

[0037] A preparation method of the above-mentioned magnesium silicate-hydrothermal carbon composite material, comprising the following steps:

[0038](1) Dissolve 4.5 g of sodium silicate in...

Embodiment 2

[0046] Application 1 of the magnesium silicate-hydrothermal carbon composite material of embodiment 1 in adsorbing methylene blue dye in waste water:

[0047] In three groups of methylene blue aqueous solution (group 1, group 2 and group 3, each group of 5 pieces of 20mL each, the methylene blue concentrations of 5 pieces of each group were 50mg / L, 70mg / L, 85mg / L, 150mg / L, 240mg / L, respectively. L, pH = 5.3), 5 mg of the magnesium silicate-hydrothermal carbon composite material of Example 1 was added respectively, the first group was placed in a constant temperature water bath at 25 °C and 170 rpm for shaking for 24 hours; the second group was placed at 35 °C, The adsorption was completed by shaking in a constant temperature water bath at 170 rpm for 24 hours; the third group was placed in a constant temperature water bath at 45°C and 170 rpm and shaken for 24 hours. After the completion of each group, 10ml of the treated solution was passed through a 0.22μm water filter membr...

Embodiment 3

[0049] Application one of the magnesium silicate-hydrothermal carbon composite material of embodiment 1 in adsorbing cadmium in wastewater:

[0050] In the three groups of cadmium-containing aqueous solutions (group 1, group 2 and group 3, each group of 6 20mL, the cadmium concentration of each group of 6 were 30mg / L, 35mg / L, 40mg / L, 45mg / L, 50mg / L, 55mg / L, pH = 5.3), 5mg of the magnesium silicate-hydrothermal carbon composite material of Example 1 was added respectively, the first group was placed in a constant temperature water bath at 25°C and 170rpm and shaken for 24h; the second group Placed in a constant temperature water bath at 35°C and 170 rpm for 24 hours of shaking; the third group was placed in a constant temperature water bath at 45°C and 170 rpm and shaken for 24 hours to complete the adsorption. After completion, 10 ml of the treated solution in each group was passed through a 0.22 μm aqueous filter membrane, and the content of cadmium in each filtrate was dete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com