High-power SiC submerged arc welding power supply

A technology of submerged arc welding and high power, applied in the field of high power SiC submerged arc welding power supply, can solve the problems of difficult to improve dynamic characteristics of power supply, small capacity of MOSFET single tube, weak thermal tolerance of IGBT, etc., and achieve ultra-high-speed dynamic response performance, improved speed and accuracy, easy effects of welding process quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

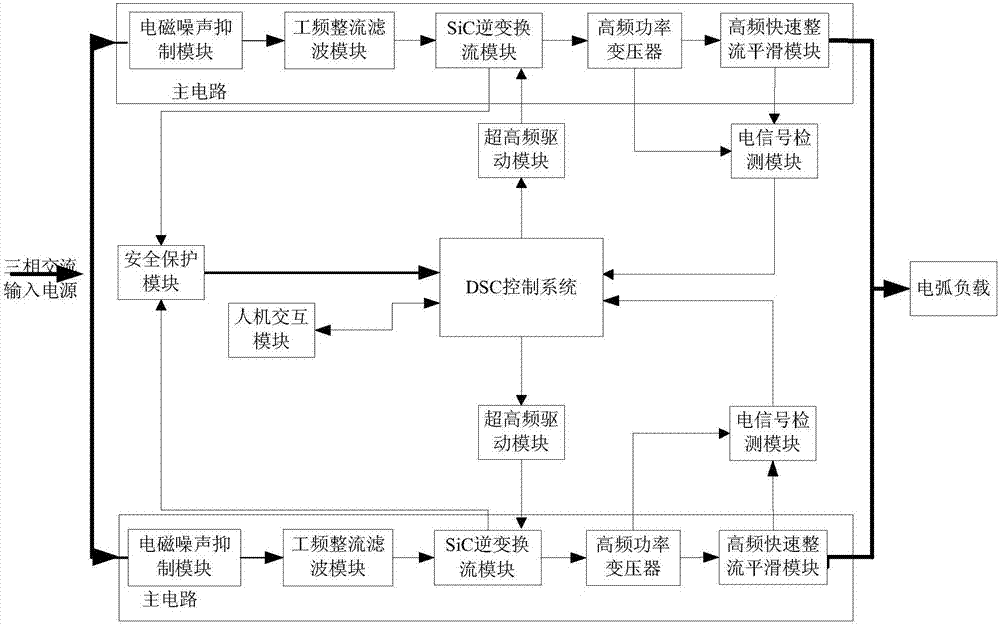

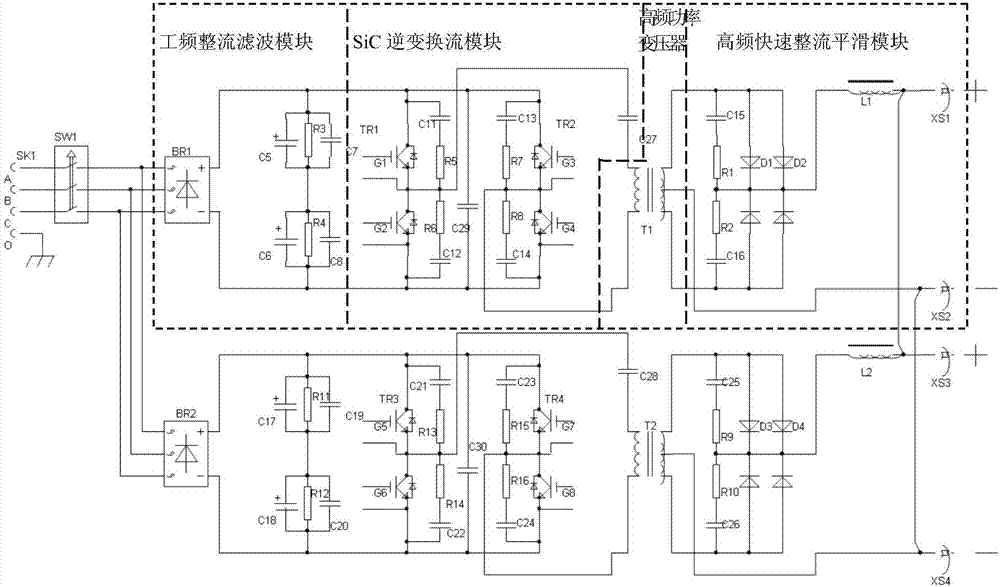

[0039] Such as Figure 1 to Figure 7 As shown, the high-power SiC submerged arc welding power supply in this embodiment includes two main circuits and a digital control circuit; each main circuit includes an electromagnetic noise suppression module, a power frequency rectification and filtering module, a SiC inverse converter module, A high-frequency power transformer and a high-frequency fast rectifying and smoothing module; wherein, the electromagnetic noise suppression module is connected to a three-phase AC input power supply; the high-frequency fast rectifying and smoothing module is connected to an arc load.

[0040] The digital control circuit includes a DSC control system, and a human-computer interaction module, a safety protection module, an ultra-high frequency drive module and an electrical signal detection module respectively connected with the DSC control system. There is one DSC control system, one human-computer interaction module and one safety protection modu...

Embodiment 2

[0063] The difference between the high-power SiC submerged arc welding power source of this embodiment and the first embodiment is that in this embodiment, there is one main circuit; DSC control system, human-computer interaction module, safety protection module, ultra-high frequency drive module and electrical signal detection There are one module respectively; the human-computer interaction module, safety protection module, UHF drive module and electrical signal detection module are respectively connected with the DSC control system; the UHF drive module is connected with the SiC inverse converter module; the safety protection module is connected with the SiC inverse The conversion flow module is connected; the electric signal detection module is respectively connected with the high-frequency power transformer and the high-frequency fast rectification smoothing module. The rest of the structure of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0065] The difference between the high-power SiC submerged arc welding power source of this embodiment and the first embodiment is that in this embodiment, there are more than three main circuits, and the number of main circuits can be set according to specific output power requirements. One DSC control system, one human-computer interaction module and one safety protection module; the number of UHF drive modules and electrical signal detection modules is the same as that of the main circuit; the human-computer interaction module, safety protection module, and UHF drive module The sum electric signal detection module is respectively connected with the DSC control system; the safety protection module is respectively connected with each ultra-high frequency drive module; , the high-frequency power transformer and the high-frequency fast rectifying smoothing module are respectively connected to the same electrical signal detection module. The rest of the structure of this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com