Single donor-doped positive temperature coefficient thermal-sensitive ceramic and preparation method thereof

A technology of positive temperature coefficient and heat-sensitive ceramics, which is applied in the field of single donor-doped positive temperature coefficient heat-sensitive ceramics and its preparation, can solve the problems of low breakdown voltage, small dispersion of room temperature resistance and high breakdown voltage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

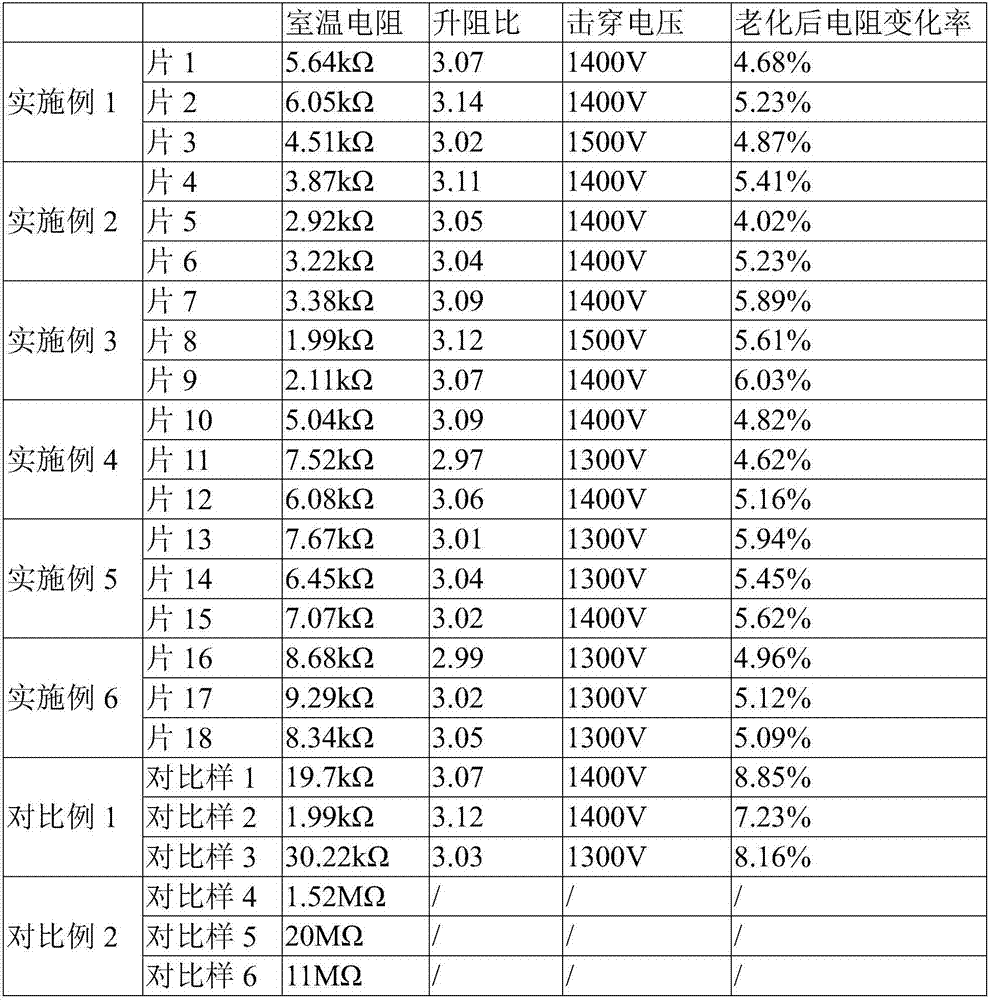

Examples

preparation example Construction

[0016] The first aspect of the present invention provides a method for preparing a single-donor-doped positive temperature coefficient thermosensitive ceramic, the method comprising the following steps:

[0017] (1) BaTiO 3 , PbTiO 3 、TiO 2 and Nb 2 o 5 Carry out the first mixing and the first sintering to obtain the formula Ba 1- x Pb x TiO 3 The mixed powder of lead barium titanate;

[0018] (2) the mixed powder, SiO 2 Performing second mixing and second sintering with manganese source to obtain single donor doped positive temperature coefficient thermosensitive ceramics;

[0019]Among them, BaTiO 3 and PbTiO 3 The dosage satisfies the general formula Ba 1-x Pb x TiO 3 x in 0.15 ~ 0.25, and relative to 100mol of Ba 1-x Pb x TiO 3 ,TiO 2 The dosage is 1~2mol, Nb 2 o 5 The dosage is 0.08~0.1mol, SiO 2 The dosage is 1~3mol, MnO 2 The dosage is 0.04~0.08mol.

[0020] Preferably, the general formula Ba 1-x Pb x TiO 3 x in is 0.16 to 0.24. The prepared s...

Embodiment 1

[0046] (1) Add 120 parts by weight of distilled water (barium titanate, lead titanate, titanium dioxide, The weight ratio of the total amount of diniobium to water is 1:1.2) after ball milling for 4 hours (the diameter of the grinding ball is 4mm, and the weight ratio to water is 1:0.5), and dried at 100°C, it is a premixed powder. The particle diameter is 2 μm;

[0047] The premixed powder is sintered for the first time. The sintering procedure is to heat from room temperature to 1150 °C at a heating rate of 5 °C / min, and keep it for 2 hours; Mixed powder of lead barium acid. Among them, the general formula of barium lead titanate is Ba 1-x Pb x TiO 3 , x is 0.16;

[0048] (2) According to 100 parts by weight of mixed powder, 0.8 parts by weight of silicon dioxide, the concentration of 8.5ml is 0.5% by weight of Mn(NO 3 ) 2 solution (converted to MnO 2 0.02 parts by weight).

[0049] After the mixed powder is pulverized and ground, it is sieved with a 120-mesh sieve,...

Embodiment 2

[0053] (1) Add 120 parts by weight of distilled water (barium titanate, lead titanate, titanium dioxide, The weight ratio of the total amount of diniobium to water is 1:1.2) after ball milling for 5 hours (the diameter of the grinding ball is 4mm, and the weight ratio to water is 1:0.4), and dried at 120°C, it is a premixed powder. The particle diameter is 1 μm;

[0054] The premixed powder is subjected to the first sintering. The sintering procedure is to heat from room temperature to 1100 °C at a heating rate of 3 °C / min, and keep the temperature for 1.5 h; then to cool down to room temperature at a cooling rate of 5 °C / min. Mixed powder of lead barium titanate. Among them, the general formula of barium lead titanate is Ba 1-x Pb x TiO 3 , x is 0.24;

[0055] (2) get 100 parts by weight of mixed powder, 0.8 parts by weight of silicon dioxide, and 8.5ml concentration of 0.5% by weight of Mn(NO 3 ) 2 solution (converted to MnO 2 0.02 parts by weight).

[0056] After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com