Automobile door sealing rubber

A technology for sealing rubber and automobile doors, applied in the field of automobile rubber materials, can solve the problems of high density and hardness of dense rubber, poor sealing performance, wear and other problems, and achieve strong thermal insulation performance, good insulation performance, and high chemical stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

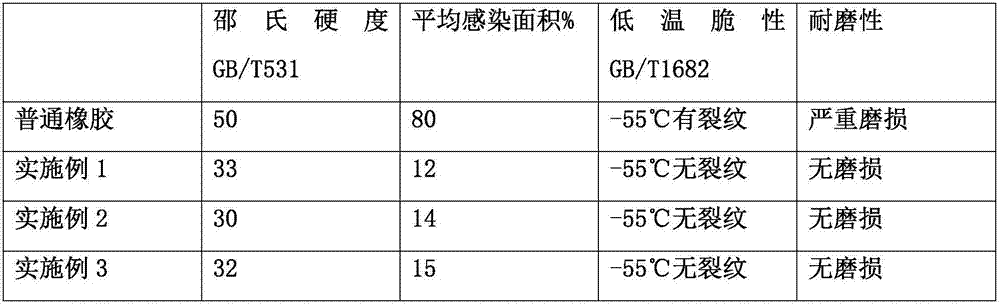

Examples

Embodiment 1

[0017] The components of the automobile door sealing rubber of the present invention are calculated in parts by weight: 30 parts of basalt fiber, 15 parts of nitrile rubber, 14 parts of vermiculite sheet, 7 parts of cadmium diethyldithiocarbamate, 5 parts of sulfur, high 6 parts of wear-resistant carbon black, 1 part of anti-aging agent, and 0.5 part of defoamer.

[0018] The preparation method of described rubber is:

[0019] Step 1: drop the nitrile rubber into the open mill and stir for 5 minutes;

[0020] Step 2: Put the vermiculite flakes into the open mill after roasting at a high temperature of 1200°C, and then add the remaining components into the open mill for mixing to obtain the mixed rubber;

[0021] Step 3: Routinely vulcanize the mixed rubber to obtain rubber.

Embodiment 2

[0023] Each component of the automobile door sealing rubber of the present invention is calculated by weight: 41 parts of basalt fiber, 18 parts of nitrile rubber, 12 parts of vermiculite sheet, 4 parts of cadmium diethyldithiocarbamate, 3 parts of sulfur, high 7 parts of wear-resistant carbon black, 2 parts of anti-aging agent, and 0.8 part of defoamer.

[0024] The preparation method of described rubber is:

[0025] Step 1: drop the nitrile rubber into the open mill and stir for 8 minutes;

[0026] Step 2: After the vermiculite flakes are roasted at a high temperature of 1000°C, they are put into the open mill, and then the remaining components are added into the open mill for mixing to obtain the rubber compound;

[0027] Step 3: Routinely vulcanize the mixed rubber to obtain rubber.

Embodiment 3

[0029] The components of the automobile door sealing rubber of the present invention are calculated in parts by weight: 50 parts of basalt fiber, 23 parts of nitrile rubber, 18 parts of vermiculite sheet, 6 parts of cadmium diethyldithiocarbamate, 4 parts of sulfur, high 8 parts of wear-resistant carbon black, 3 parts of anti-aging agent, and 1 part of defoamer.

[0030] The preparation method of described rubber is:

[0031] Step 1: drop the nitrile rubber into an open mill and stir for 10 minutes;

[0032] Step 2: Put the vermiculite flakes into the open mill after roasting at a high temperature of 1120°C, and then add the remaining components into the open mill for mixing to obtain the mixed rubber;

[0033] Step 3: Routinely vulcanize the mixed rubber to obtain rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com