Method for determining polymerization inhibitor in acrylic acid and derivatives thereof

A technology of polymerization inhibitors and derivatives, applied in the field of analysis of organic chemical products, can solve problems such as environmental impact, strong corrosion, and odor stimulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

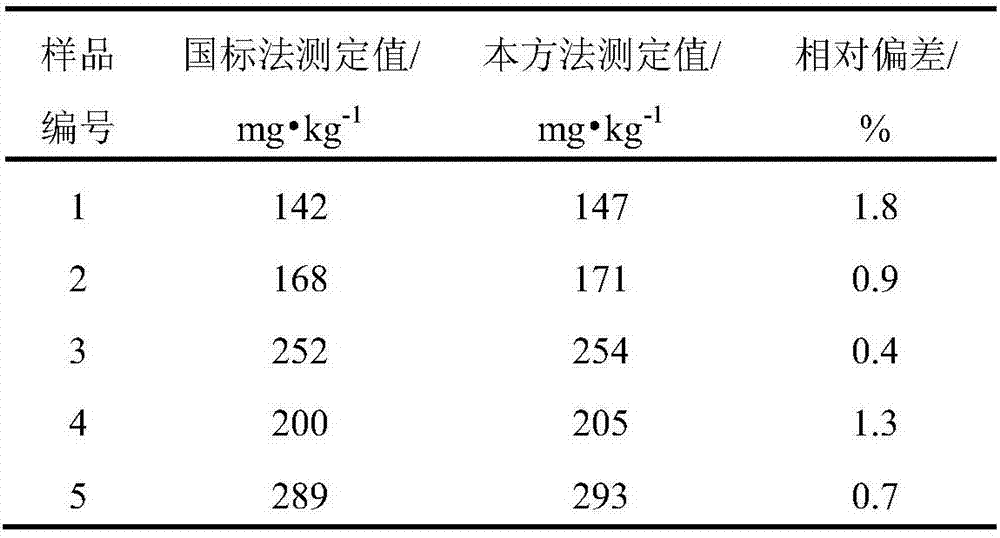

Embodiment 1

[0016] 1) Prepare acidic isopropanol solution: the volume ratio of isopropanol (AR) to 6mol / L hydrochloric acid solution is 1:0.3.

[0017] 2) Preparation of standard solution: Weigh 0.1000g MEHQ into a 100mL volumetric flask filled with 50mL of acidic isopropanol. Mix well to dissolve it completely, and dilute to the mark with acidic isopropanol to prepare a standard solution.

[0018] 3) Preparation method of sodium nitrite solution: dissolve 2 g of sodium nitrite in water and dilute to 100 mL.

[0019] 4) Drawing of the working curve: Draw 1, 2, 4, 6 and 10mL of standard solutions, pour them into 50mL volumetric flasks respectively, dilute each to the mark with acidic isopropanol, and mix thoroughly. Take 10mL of standard solutions from each of these standard solutions in turn and place them in 50mL volumetric flasks filled with about 20mL of acidic isopropanol, add 2mL of sodium nitrite solution, and dilute to the mark with acidic isopropanol. Mix well and let stand for ...

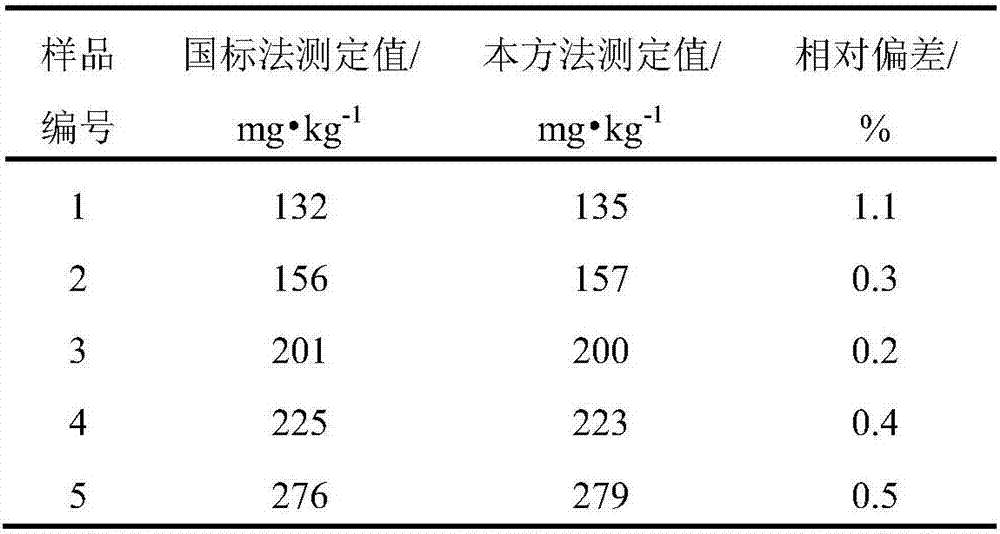

Embodiment 2

[0024] 1) Prepare acidic isopropanol solution: the volume ratio of isopropanol (AR) to 6mol / L hydrochloric acid solution is 1:0.4.

[0025] 2) Preparation of standard solution: Weigh 0.1000g TBHQ into a 100mL volumetric flask filled with 50mL of acidic isopropanol. Mix well to dissolve it completely, and dilute to the mark with acidic isopropanol to prepare a standard solution.

[0026] 3) Preparation method of sodium nitrite solution: dissolve 2 g of sodium nitrite in water and dilute to 100 mL.

[0027] 4) Drawing of the working curve: Draw 1, 2, 4, 6 and 10mL of standard solutions, pour them into 50mL volumetric flasks respectively, dilute each to the mark with acidic isopropanol, and mix thoroughly. Take 10mL of standard solutions from these standard solutions in turn, place them in 50mL volumetric flasks filled with about 20mL of acidic isopropanol, add 2.5mL of sodium nitrite solution, and dilute to the mark with acidic isopropanol. Mix well and let stand for 10min. U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com