A heteroatom-doped flexible fabric-based carbon electrode material and its preparation and application

A technology of flexible fabrics and electrode materials, applied in the directions of hybrid capacitor electrodes, carbon-silicon compound conductors, etc., can solve problems such as poor electrochemical performance, and achieve the effects of low cost, low raw material requirements, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

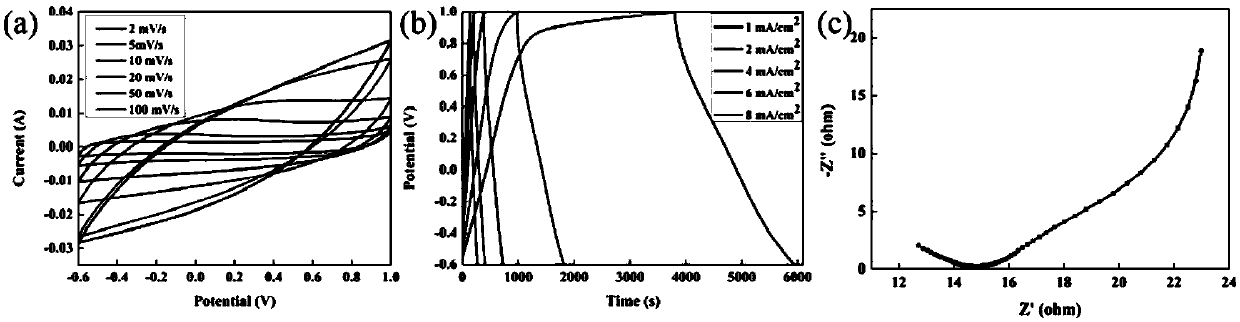

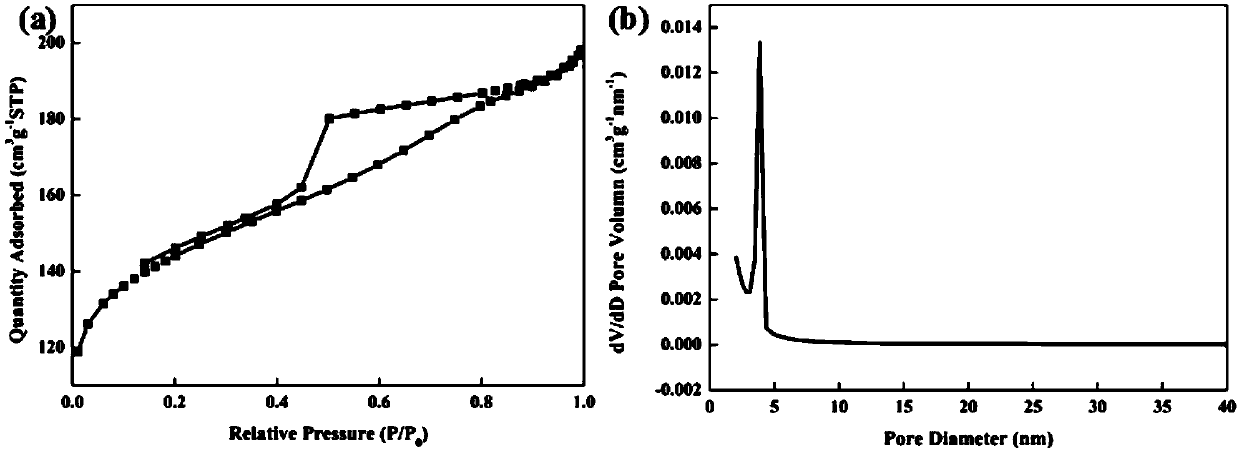

Examples

Embodiment 1

[0031] In this embodiment, reactive dyes are used to dye pure cotton fabric, and carbonized pure cotton fabric electrodes are prepared by carbonization process.

[0032] (1) Put 1 g of pure cotton fabric in a sodium hydroxide solution with a concentration of 15 g / L, shake it at a constant temperature at 95 °C for 1 h, wash it with deionized water until it is neutral, and dry it at 60 °C until it reaches a constant weight.

[0033] (2) Add the fabric in step (1) to 10% (o.w.f.) dye liquor (referring to the weight of the dye relative to the fabric is o.w.f.), the bath ratio is 1:50, add salt after dyeing at 60°C for 15 minutes , continue dyeing at 60°C for 15 minutes, then heat up to 90°C at a rate of 2°C / min, add soda ash, fix the color at 90°C for 30 minutes, cool down after dyeing, take out the sample, wash with cold water and soap (soap flakes) 2g / L, soda ash 2g / L, 95°C, 10min, liquor ratio 1:30), washing with water, and drying.

[0034] (3) Clean the fabric in step (2) wit...

Embodiment 2

[0044] In this example, acid dyes are used to dye silk fabrics, and carbonized silk fabric electrodes are prepared by carbonization process.

[0045](1) Add 1g of silk fabric to the dye solution of Weak Acid Red 2% (o.w.f.), Ammonium Sulfate 10% (o.w.f.), Sodium Sulfate 10% (o.w.f.), the bath ratio is 1:100, make up the required amount according to the bath ratio Water volume, after the dyeing bath is configured, squeeze the silk fabric soaked in water and put it into the dyeing bath to start dyeing. Under the condition of constant stirring, dye at 60°C, and then gradually heat up to 2°C / min. 90°C, keep warm and dye for 60 minutes, take out the sample after dyeing, wash with cold water, wash with water, and dry.

[0046] (3) Clean the fabric in step (2) with deionized water, and then dry it.

[0047] (4) The treated fabric is placed in a quartz porcelain boat, placed in the center of the quartz tube of the tube furnace, and high-purity nitrogen is passed through the whole pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com