Titanium alloy laser welding protection method

A laser welding and titanium alloy technology, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of unfavorable laser penetration welding and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

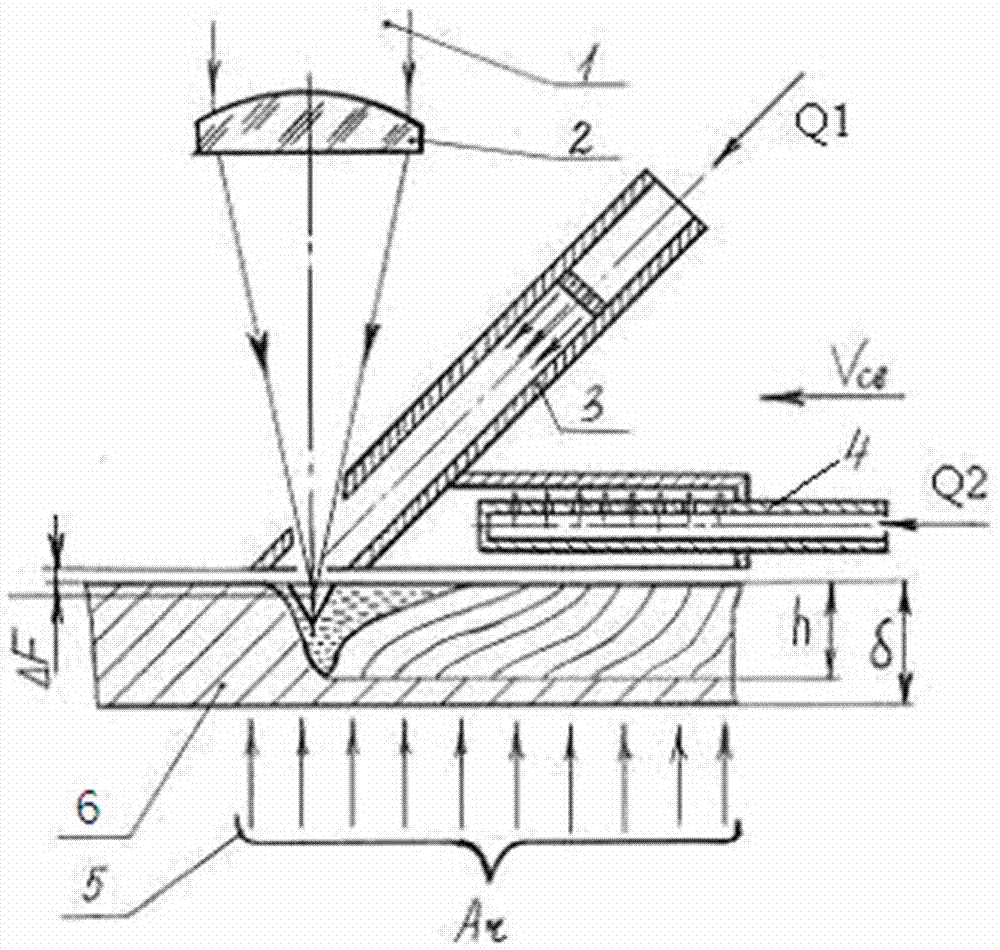

Method used

Image

Examples

Embodiment 1

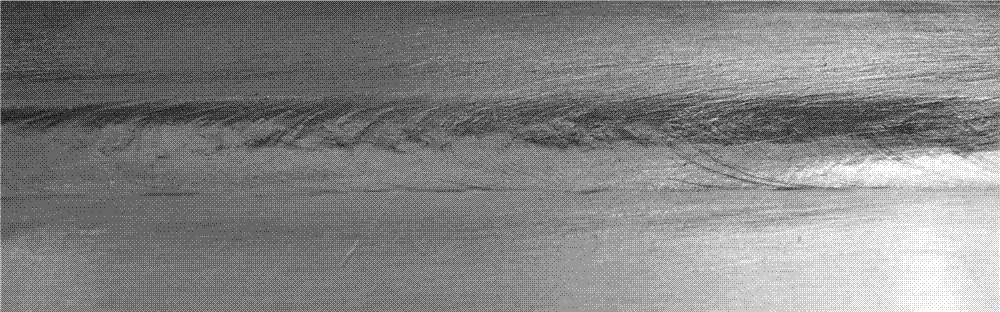

[0027] Under the designed welding protection system, the 2.5mm thick BT20 alloy is laser welded, the welding speed is 18m / h, the defocus is -1mm, and the laser power is 1.0kW. like figure 2 As shown, the appearance of the upper surface of the weld of 2.5mm thick BT20 alloy is easy to see from its surface color and state, even if the weld width is large (weld shape coefficient K=2~3), it will not be on the weld surface. Oxides and nitrides are formed.

Embodiment 2

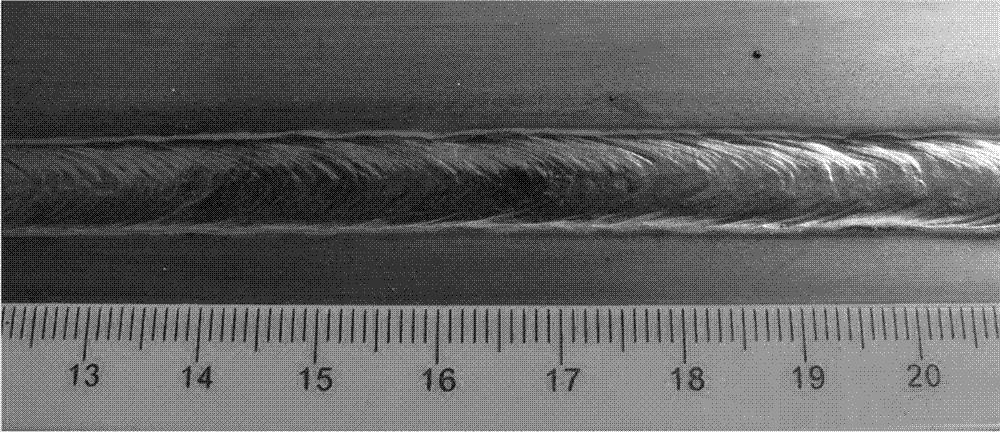

[0029] Under the designed welding protection system, the 6mm thick BT6 alloy is laser welded, the welding speed is 36m / h, the defocus is -2mm, and the laser power is 5 kW (weld shape coefficient K≈1.3). like image 3 As shown, it is the appearance of the upper surface of the BT6 alloy weld with a thickness of 6mm. The silver weld proves that the atmosphere does not enter the molten pool, and the gas protection effect is good. like Figure 4 As shown, it is a metallographic picture of a 6mm BT6 alloy butt joint. It can be seen that there are no metallurgical pores, indicating that the welding process is stable.

Embodiment 3

[0031] Under the designed welding protection system, the 4.6mm thick BT22 alloy and the 1.6mm BT22 alloy sample are welded, the welding speed is 60m / h, the defocus is -2mm, and the laser power is 3.0kW. like Figure 5 Shown is the appearance of the upper surface of the 4.6mm thick BT22 alloy and 1.6mm thick BT22 alloy butt joint laser welded by the protection system. The color and condition of the weld seam confirm that the protection method can be used to weld samples of different thicknesses within 3mm.

[0032] Table 1 Chemical composition used in titanium alloy test (mass ratio %)

[0033] NO Alloy grade C Fe Si Cr Mo V N Al Zr O H 1 ВТ6 <0.1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com