Method for preparing nitrogen, sulfur and potassium from polyhalite

A polyhalite and nitrogen-sulfur-potassium technology, which is applied in the field of nitrogen-sulfur-potassium compound fertilizer production, can solve problems such as the infeasibility of industrial production, and achieve the effects of low production cost, good water solubility, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

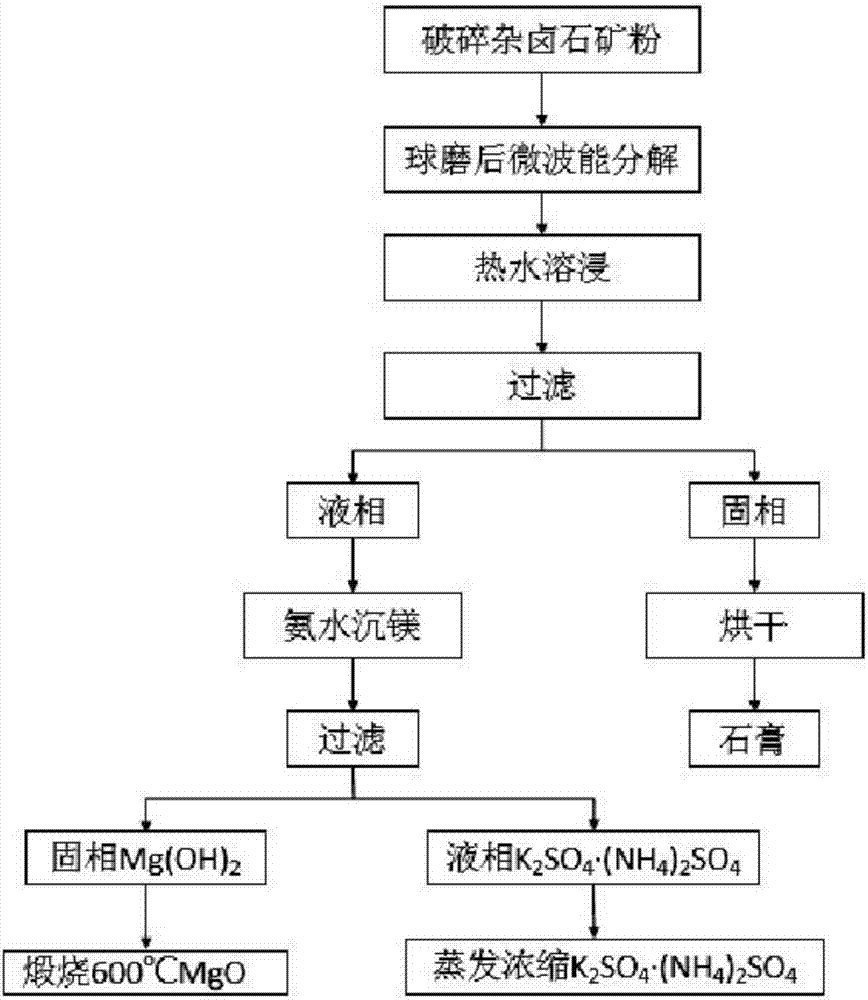

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

[0023] like figure 1 As shown, the method for preparing nitrogen, sulfur, and potassium from polyhalite includes: grinding polyhalite into 120-mesh ore powder, heating it in a microwave oven (200°C) for 10 minutes, and then leaching it with a hot solution to carry out Solid-liquid separation, the liquid phase is K 2 SO 4 ,MgSO 4 solution, solid phase is CaSO 4 (Gypsum) product, the liquid phase is precipitated with 25% (wt) ammonia water to remove magnesium, and then filtered, the solid phase is Mg(OH) 2 , After calcination at 600°C, light MgO products can be obtained. The liquid phase was concentrated and crystallized by evaporation to obtain K 2 SO 4 ·(NH 4 ) 2 SO 4 Product, this product is nitrogen-sulfur-potassium ternary compound fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com