Anti-shellfish coating for concrete surface protection of water-conveying tunnel

A technology for concrete surfaces and water tunnels, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as unsuitable repair and protection of freshwater shellfish, improve operating efficiency and concrete life, and reduce shellfish erosion , improve the effect of anti-carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the first component is as follows: under the condition of 40° C. and stirring speed of 400-1200 rpm, mix epoxy resin, toughening modifier and active diluent in a reaction kettle for 30 minutes. Then, the heating is stopped, and the thixotropic agent and the nano-mixed filler are added into the reaction kettle, and the stirring is continued until all the materials are mixed evenly. Grinding the mixture with a grinder to a fineness of ≤50 μm is the first component.

[0024] The second component includes benzyl alcohol diluent, nano-mixed filler, and at least one of polyamide curing agent, phenalkamine curing agent, and modified fatty amine curing agent. In terms of mass percentage, the contents of benzyl alcohol diluent, nano-mixed filler, polyamide curing agent (600#, V140), phenalkamine curing agent and modified fatty amine amine curing agent are 5-10 parts and 100-160 parts respectively , 30-80 copies, 20-70 copies, 20-80 copies. Wherein, th...

Embodiment 1

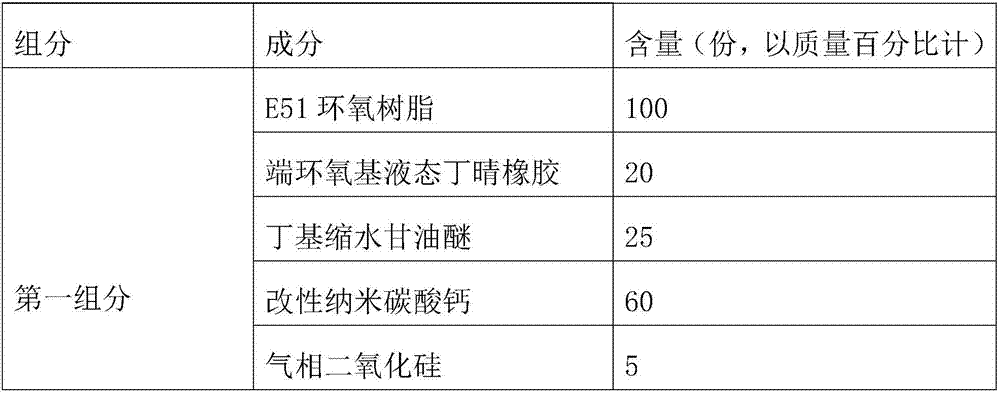

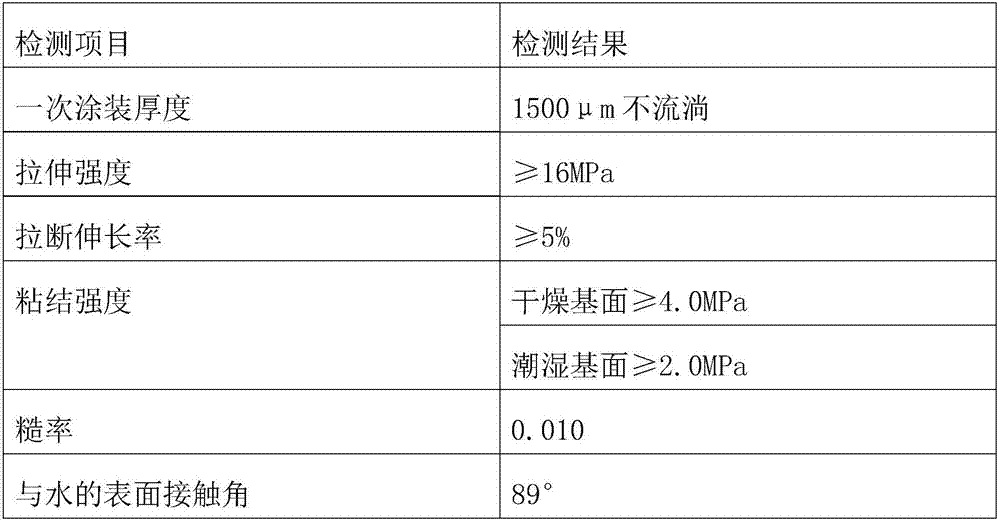

[0032] Table 1 and table 2 are respectively the formulas of the concrete surface protection of the water delivery tunnel and the anti-shellfish coating provided by the present invention, wherein, the preparation method of the protective coating is:

[0033] 1. The preparation method of the first component: Add E51 epoxy resin, epoxy-terminated liquid NBR as a toughening agent, and butyl glycidyl ether as a diluent into the reaction kettle according to the following ratio, and stir and mix evenly. Then add modified nano-calcium carbonate, fumed silicon dioxide, polytetrafluoroethylene micropowder, and silicon powder according to the following proportions, and mix well. Then, the mixture is ground to a fineness of less than 20 μm by using a three-roll mill, and loaded into barrels to obtain the first component.

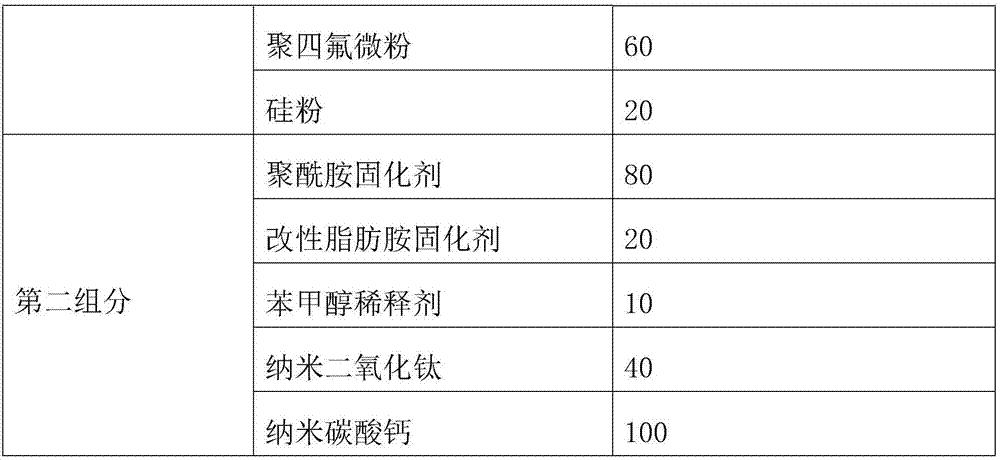

[0034] 2. The preparation method of the second component: add polyamide curing agent (600#), modified fatty amine curing agent (593), benzyl alcohol diluent, nano-titan...

Embodiment 2

[0042]Table 3 and table 4 are respectively the formulation and performance characteristics of the concrete surface protection of the water delivery tunnel and the anti-shellfish coating provided by the present invention, wherein, the preparation method of the protective coating is:

[0043] 1. The preparation method of the first component: Add epoxy resin, epoxy-terminated liquid NBR as a toughening agent, and diluent butanediol diglycidyl ether into the reaction kettle according to the following ratio, and stir and mix evenly. Then add modified nano-calcium carbonate, fumed silicon dioxide, polytetrafluoroethylene micropowder, and silicon powder according to the following proportions, and mix well. Then, the mixture is ground to a fineness of less than 20 μm by using a three-roll mill, and loaded into barrels to obtain the first component.

[0044] 2. The preparation method of the second component: Add polyamide curing agent (600#) and phenalkamine curing agent (T31), benzyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com