Resource utilization method of agricultural organic waste

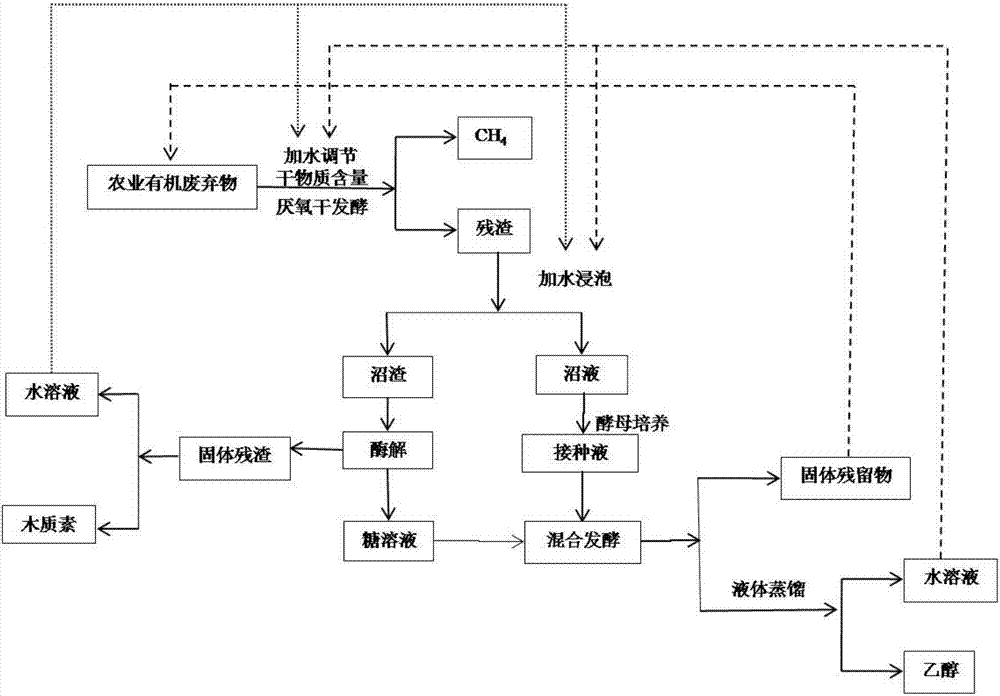

A technology for recycling organic waste, applied in the field of resource utilization of agricultural organic waste, can solve the problems of low methane yield, limited utilization of biogas slurry and biogas residue, etc., to improve purity, improve components and structure , The effect of improving the process yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, the resource utilization of agricultural organic waste is carried out according to the following steps:

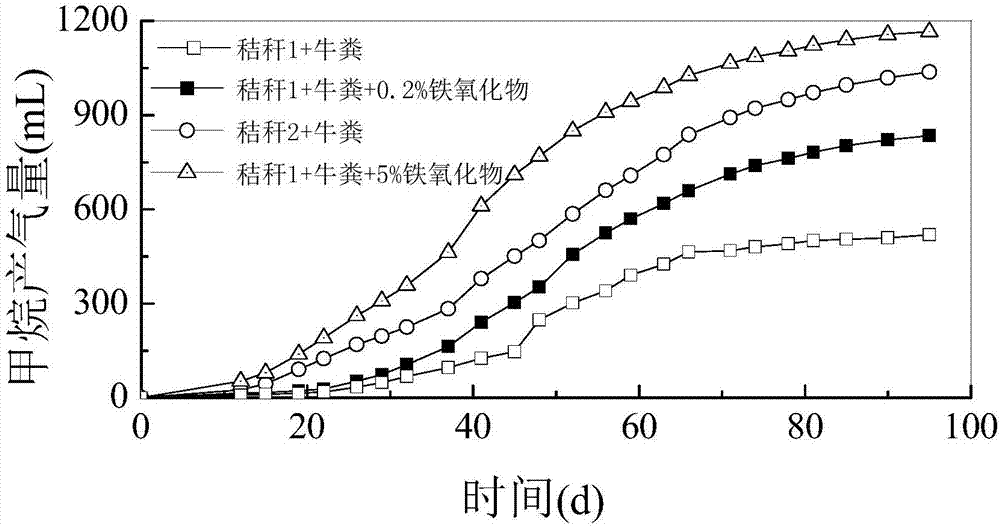

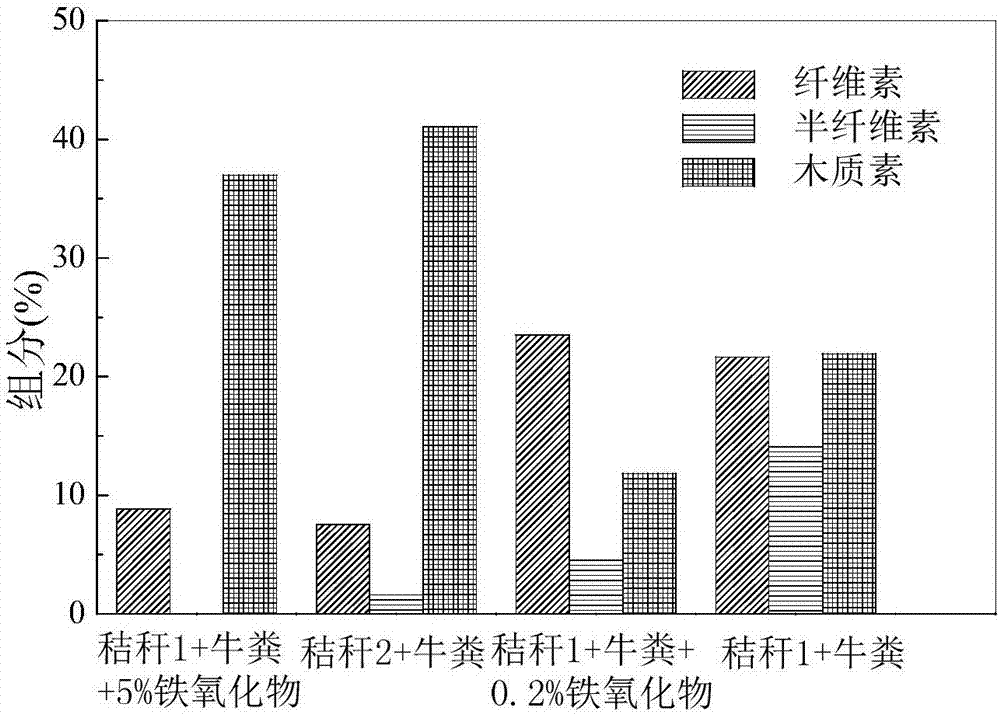

[0038] 1. Anaerobic dry fermentation test

[0039] A 250mL serum bottle was used as a reactor, and a total of 12 reactors were set up, which were divided into four groups, and each group had three parallel samples. The agricultural organic waste used in each group was: 5g straw 1+1.25g cow dung (based on dry matter mass), 5g straw 1+1.25g cow dung+iron oxide (the amount added is calculated as Fe, which is 0.2% of the total mass of volatile solids in straw 1 and cow dung), 5g straw 2+1.25g cow dung, 5g straw 1 +1.25g cow dung+iron oxide (the amount added is calculated as Fe, which is 5% of the total mass of volatile solids in straw 1 and cow dung). Add appropriate amount of water to control the dry matter content in the solution of each group of reactors to be 20%.

[0040] Anaerobic dry fermentation was carried out on each group of reactors, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com