Process method for producing building gypsum powder by utilizing citric acid gypsum

A technology of citric acid gypsum and building gypsum powder, which is applied in the comprehensive treatment and reuse of solid waste, and the field of producing building gypsum by using citric acid gypsum, which can solve the problems of short residence time, reduce moisture, and uneven heating of materials, so as to reduce the failure rate and maintenance costs, reduce production and operation costs, and strive for compact process layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

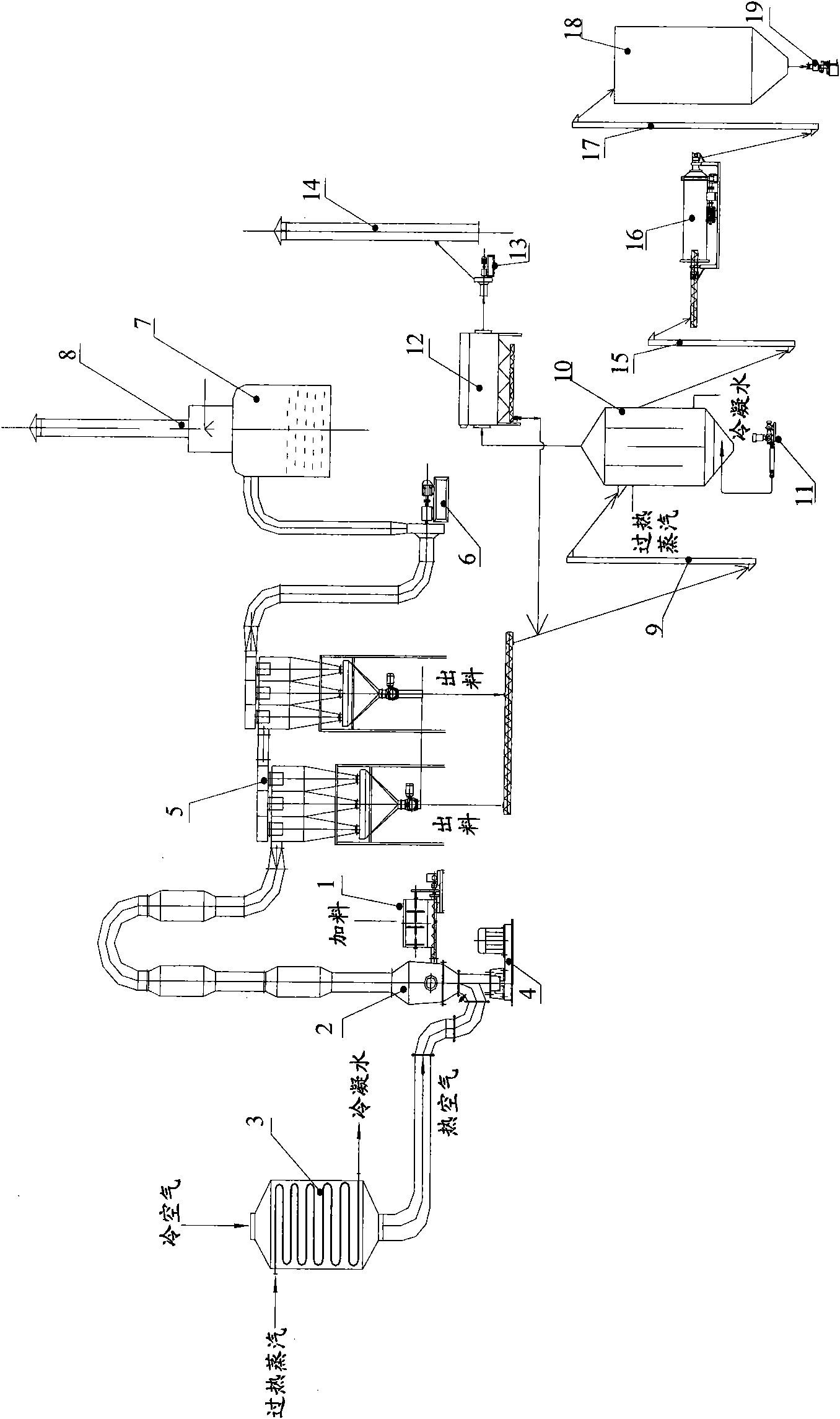

Method used

Image

Examples

Embodiment 1

[0035] 1. Transport the citric acid gypsum that has been stacked and homogenized for one month to the feed hopper, and send it to the airflow dryer through the feeder;

[0036] 2. The cold air enters the dryer from the bottom of the dryer after heat exchange by the high-temperature exhaust gas of the power plant into high-temperature hot air, and the drying temperature is 400°C;

[0037] 3. Citric acid gypsum performs mass transfer and heat exchange with hot air in the dryer. At the same time, the dispersing device at the bottom of the dryer continuously disperses the material to enhance the heat transfer effect. After drying, the attached water content of the material is 2.46%. ;

[0038] 4. The dried material is separated from the material by the secondary cyclone dedusting, and the separated material enters the fluidized calciner;

[0039] 5. The material enters the calcination furnace through the hoist for continuous calcination, the calcination temperature is 180°C, and ...

Embodiment 2

[0045] 1. Transport the citrate gypsum that has been stacked and homogenized for 2 months to the feed hopper, and send it to the airflow dryer through the feeder;

[0046] 2. The cold air enters the dryer from the bottom of the dryer after heat exchange by the high-temperature exhaust gas of the power plant into high-temperature hot air, and the drying temperature is 420°C;

[0047] 3. Citric acid gypsum performs mass transfer and heat exchange with hot air in the dryer. At the same time, the dispersing device at the bottom of the dryer continuously disperses the material to enhance the heat transfer effect. After drying, the attached water content of the material is 2.12%. ;

[0048] 4. The dried material is separated from the material by the secondary cyclone dedusting, and the separated material enters the fluidized calciner;

[0049] 5. The material enters the calcination furnace through the hoist for continuous calcination, the calcination temperature is 220°C, and the c...

Embodiment 3

[0055] 1. Transport the citric acid gypsum that has been stacked and homogenized for 3 months to the feed hopper, and send it to the airflow dryer through the feeder;

[0056] 2. The cold air enters the dryer from the bottom of the dryer after heat exchange by the high-temperature exhaust gas of the power plant into high-temperature hot air, and the drying temperature is 450°C;

[0057] 3. The citric acid gypsum performs mass transfer and heat exchange with the hot air in the dryer. At the same time, the dispersing device at the bottom of the dryer continuously disperses the material to enhance the heat transfer effect. After drying, the attached water content of the material is 1.64%. ;

[0058] 4. The dried material is separated from the material by the secondary cyclone dedusting, and the separated material enters the fluidized calciner;

[0059] 5. The material enters the calcination furnace through the hoist for continuous calcination, the calcination temperature is 200°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com