Epitaxial wafer of gallium nitride-based light-emitting diode and preparation method thereof

A light-emitting diode, gallium nitride-based technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of low luminous efficiency of light-emitting diodes, achieve the effects of improving energy band difference, improving luminous efficiency, and improving crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

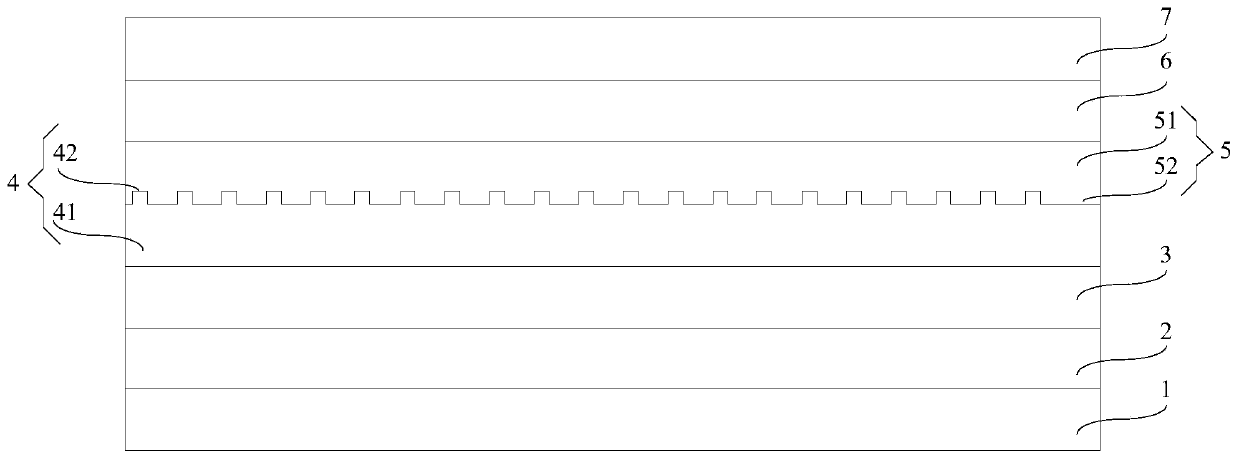

[0037] An embodiment of the present invention provides an epitaxial wafer of a gallium nitride-based light-emitting diode, see figure 1 , the epitaxial wafer includes a sapphire substrate 1, and a gallium nitride buffer layer 2, an undoped gallium nitride layer 3, an N-type gallium nitride layer 4, a multi-quantum well layer 5, P-type AlGaN layer 6 and P-type GaN layer 7 .

[0038] In this embodiment, the N-type GaN layer 4 includes an N-type GaN layer body 41 and a plurality of protrusions 42, the N-type GaN layer body 41 is a columnar structure, and the N-type GaN layer body 41 The bottom surface of the N-type GaN layer body 41 is disposed on the undoped GaN layer 3 , and a plurality of protrusions 42 are arranged in an array on the top surface of the N-type GaN layer body 41 . The multi-quantum well layer 5 includes a multi-quantum well layer body 51 and a filling part 52, and the filling part 52 is arranged on the N-type gallium nitride layer body 41 exposed between the p...

Embodiment 2

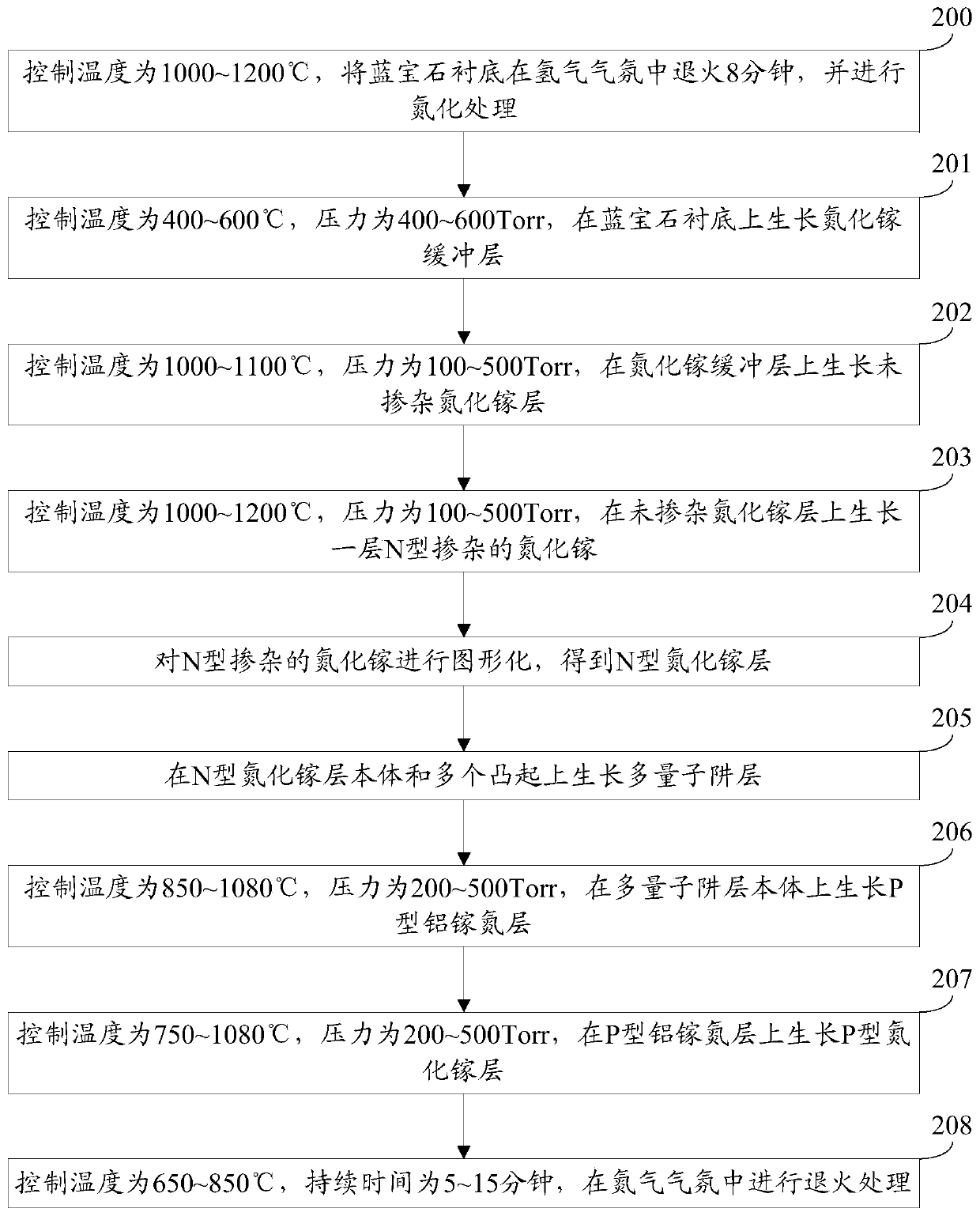

[0061] An embodiment of the present invention provides a method for preparing an epitaxial wafer of a gallium nitride-based light-emitting diode, which is suitable for preparing the epitaxial wafer provided in Embodiment 1. See figure 2 , the preparation method comprises:

[0062] Step 200: Control the temperature to 1000-1200° C., anneal the sapphire substrate in a hydrogen atmosphere for 8 minutes, and perform nitriding treatment.

[0063] Understandably, step 200 may serve to clean the surface of the sapphire substrate.

[0064] In this embodiment, controlling the temperature and pressure both refers to controlling the temperature and pressure in the reaction chamber for growing epitaxial wafers, which will not be described in detail below.

[0065] In this embodiment, the sapphire substrate adopts [0001] crystal orientation sapphire.

[0066] Step 201: Control the temperature to 400-600° C. and the pressure to 400-600 Torr to grow a GaN buffer layer on the sapphire subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com