Iron, cobalt and nitrogen codoped carbon catalyst and preparation method and application thereof

A carbon catalyst and co-doping technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of single active site of TM-N-C catalyst, decreased catalytic activity of oxygen reduction, and uneven dispersion of active sites, etc. Achieve the effects of excellent oxygen reduction catalytic activity, good metal nanoparticle dispersion, and excellent mass transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of Iron / Cobalt Bimetallic Zeolite Imidazolate Framework Precursor

[0036]Weigh 208.5 mg of ferrous sulfate and 654.8 mg of cobalt nitrate and dissolve in 160 mL of methanol, weigh 3.9408 g of 2-methylimidazole and dissolve in 160 mL of methanol. 2 half an hour to remove dissolved O in the solvent 2 , to prevent Fe 2+ be oxidized; pour the above salt solution into 2-methylimidazole solution, stir for 2 min to mix evenly, at 30 o C.N 2 After standing for 12 hours in a protected environment, suction filtration, washing, and at 80 o After drying at C for 8 h, the obtained product was the precursor of iron / cobalt bimetallic zeolite imidazolate framework material (named Fe,Co-ZIF(1:3) according to the feed ratio of Fe and Co).

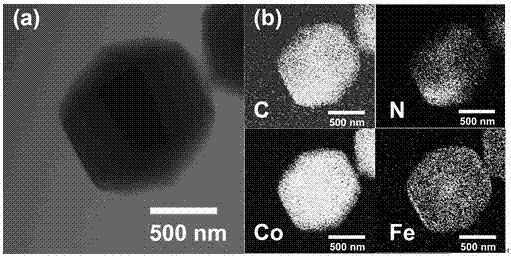

[0037] Preparation of Iron, Cobalt and Nitrogen Co-doped Carbon Catalysts

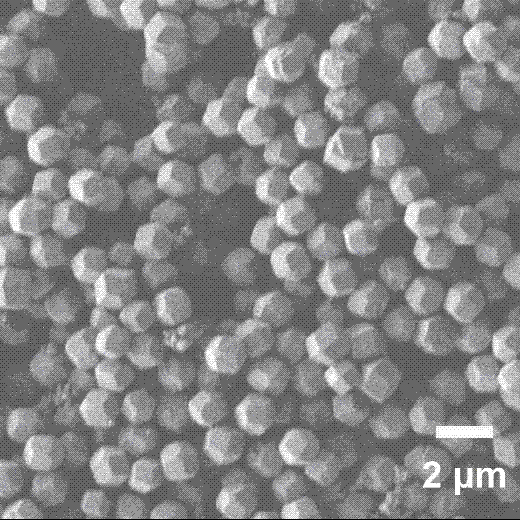

[0038] Take 200 mg of the above-mentioned iron / cobalt bimetallic zeolite imidazolate framework material precursor sample powder in a corundum crucible, and h...

Embodiment 2

[0040] Adopting the preparation process of Example 1, the difference is that the addition of ferrous sulfate becomes 139 mg, the addition of cobalt nitrate becomes 727.5 mg, and the prepared catalyst is Fe, Co, N-CNP (1:5) . Compared with the catalyst prepared in Example 1, the catalyst has negative onset potential and half-wave potential, and its catalytic activity is inferior to that of the catalyst in Example 1.

Embodiment 3

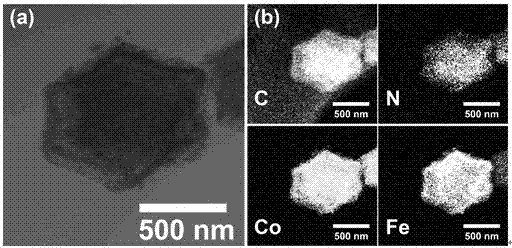

[0042] Adopt the preparation method of iron / cobalt bimetallic zeolite imidazolate framework material precursor in Example 1, the only difference is that the addition of ferrous sulfate becomes 417 mg, the addition of cobalt nitrate becomes 436.5 mg, wherein Fe 2+ / Co 2+ The molar ratio is 1:1. At this time, the morphology of the synthesized product has been completely deformed and no longer maintains a regular polyhedron structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com