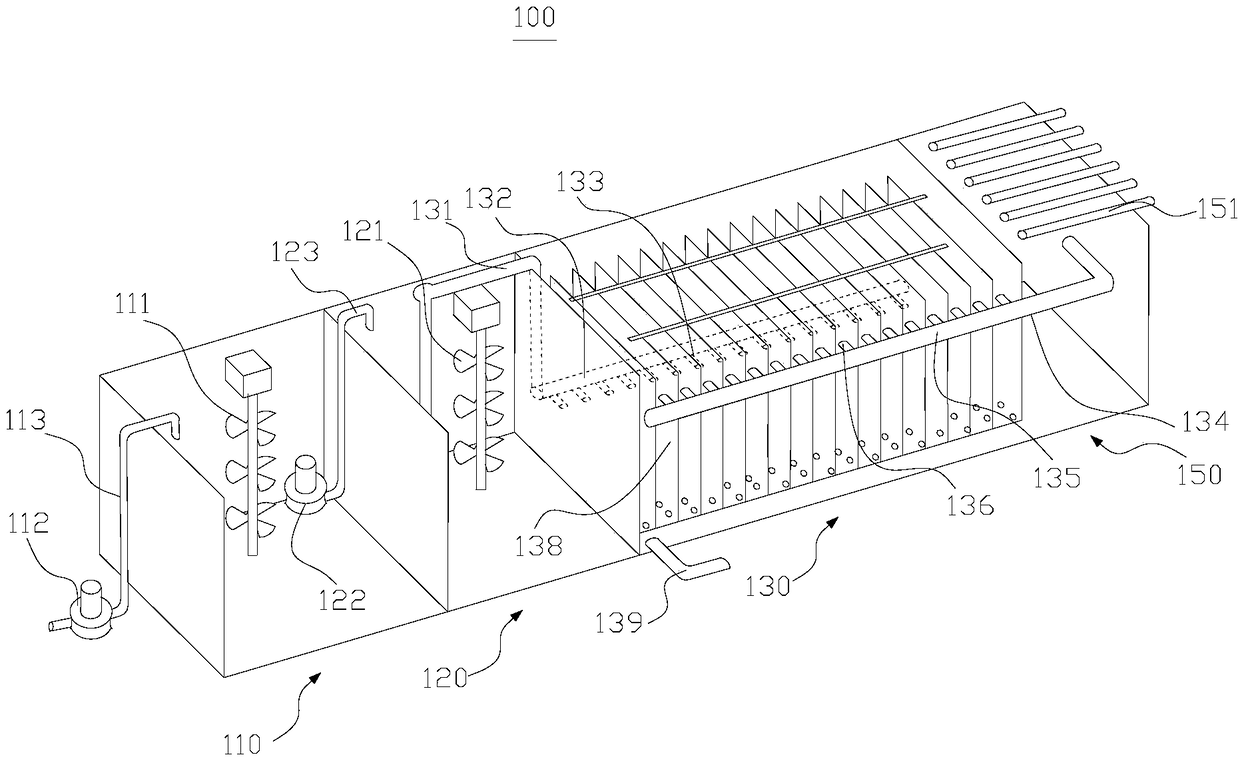

A high-efficiency treatment system and treatment method for uranium-containing wastewater

A technology of a treatment system and a treatment method, which is applied in the application field of water treatment, can solve the problems of high energy consumption, secondary pollution, and low treatment efficiency of uranium-containing wastewater, and achieves large treatment flow, secondary pollution, and difficulty in secondary pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

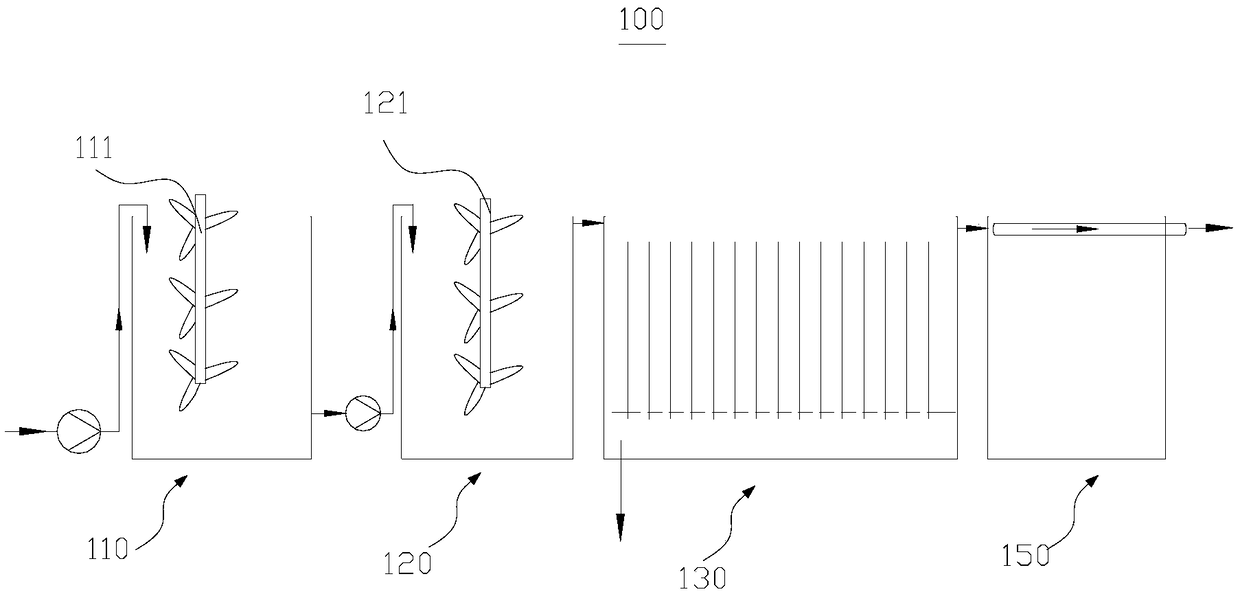

Method used

Image

Examples

Embodiment 1

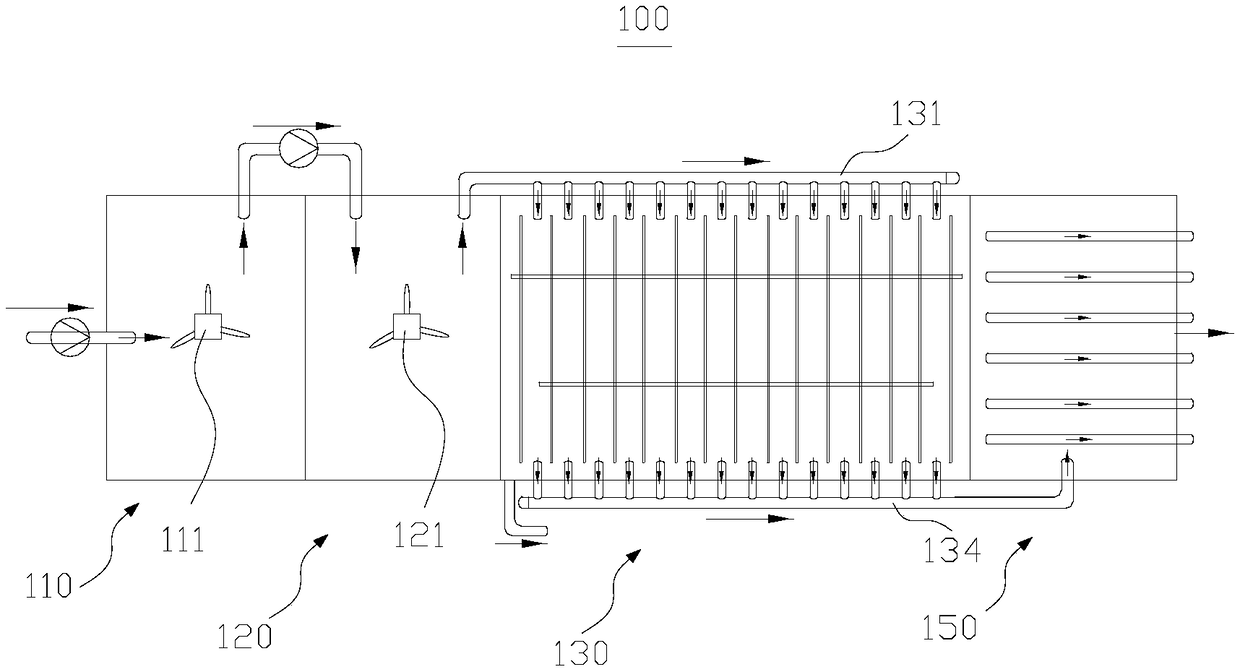

[0069] The heap leaching wastewater of a uranium tailings pond in Jiangxi was treated, the pH of the raw water was 4.0-5.0, and the uranium concentration was 4.94mg / L. Add polyaniline according to the molar ratio of organic ligand to uranium 3:1, the dosage of sodium sulfate electrolyte is 5%, and the residence time in the chelating agent adding pool 110 is 4min; The internal residence time is 4min; electrocoagulation reaction in a predetermined reactor composed of iron anode (8 pieces) and graphite cathode (7 pieces), the single electrode voltage is 1.4V, and the current density is 8mA / cm 2 , the waste water stays in the electrolytic tank 130 for 6 minutes, and the treatment capacity is 90t / d; finally, it is left in the sedimentation tank 150 for 40 minutes, and the final effluent of the sedimentation tank is taken to measure the uranium concentration of 0.02mg / L, and the iron concentration of the effluent is 0.571mg / L at this time ;Take water samples every 1h to measure the ...

Embodiment 2

[0071] The heap leaching wastewater of a uranium tailings pond in Guangzhou was treated, and the pH of the wastewater was determined to be 4.0-5.5, and the uranium concentration was 7.6mg / L. Add polyaniline according to the molar ratio of organic ligand to uranium 3:1, add 5% of electrolyte sodium sulfate, and stay in the chelating agent addition pool 110 for 4 minutes; use sodium hydroxide to adjust the pH to 6.8-7.2, The residence time in 120 is 4min; electrocoagulation reaction in a predetermined reactor composed of iron anode (8 pieces) and graphite cathode (7 pieces), the single electrode voltage is 1.3V, and the current density is 8mA / cm 2 , the residence time of wastewater in the electrolytic tank 130 is 6min, and the treatment capacity is 90t / d; finally, it is left standing in the sedimentation tank 150 for 40min, and the final effluent of the sedimentation tank is taken to measure the uranium concentration to be 0.04mg / L, and the iron concentration in the effluent is 0...

Embodiment 3

[0073] Heap leaching wastewater from a uranium tailings pond in Xinjiang was treated, the raw water had a pH of 5.5-6 and a uranium concentration of 5.05mg / L. Add polyaniline according to the molar ratio of organic ligand to uranium 2.5:1, the dosage of electrolyte sodium sulfate is 5%, and the residence time in the chelating agent addition pool 110 is 3min; The internal residence time is 5 minutes; the electrocoagulation reaction is carried out in a predetermined reactor composed of iron anode (8 pieces) and graphite cathode (7 pieces), the single electrode voltage is 1.0V, and the current density is 7mA / cm 2 , the waste water stays in the electrolytic tank 130 for 5 minutes, and the treatment capacity is 90t / d; finally, it is left in the sedimentation tank 150 for 35 minutes, and the final effluent of the sedimentation tank is taken to measure the uranium concentration of 0.015mg / L, and the iron concentration of the effluent is 0.561mg / L at this time ;Take water samples ever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com