Squab amino acid oral liquid, preparation method and application thereof

An amino acid oral liquid, pigeon technology, applied in the application, the function of food ingredients, food science and other directions, can solve problems such as affecting the taste, and achieve the effects of easy absorption, high quality taste and high amino acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation technology of embodiment 1 squab amino acid oral liquid

[0030] 1. Preparation of pigeon meat slurry

[0031] Slaughter the pigeons, wash them, take the meat, cut the meat into pieces about 2*2cm in size, add pure water according to the material-to-water ratio of 1:3, and mash them with a tissue grinder to prepare squab meat slurry.

[0032] 2. Preparation of pigeon enzymatic solution

[0033] Add 1500-1875U of flavor protease per gram of pigeon meat (the enzyme activity of flavor protease is 15000U / g), enzymolyze at 53-57°C for 6-7 hours, then heat at 95°C for 10 minutes , followed by centrifugation at 4°C and 12000r / min for 5min, the supernatant was taken, and the mass ratio of activated carbon to squab enzymolyzate was 10-15%, after adding activated carbon and standing for 2h, filtered to obtain the filtrate, which was Pigeon enzyme hydrolyzate.

[0034] 3. Deodorization

[0035] The beta-cyclodextrin is added into the filtrate according to the m...

Embodiment 2

[0039] The antioxidant capacity of embodiment 2 squab amino acid oral liquid

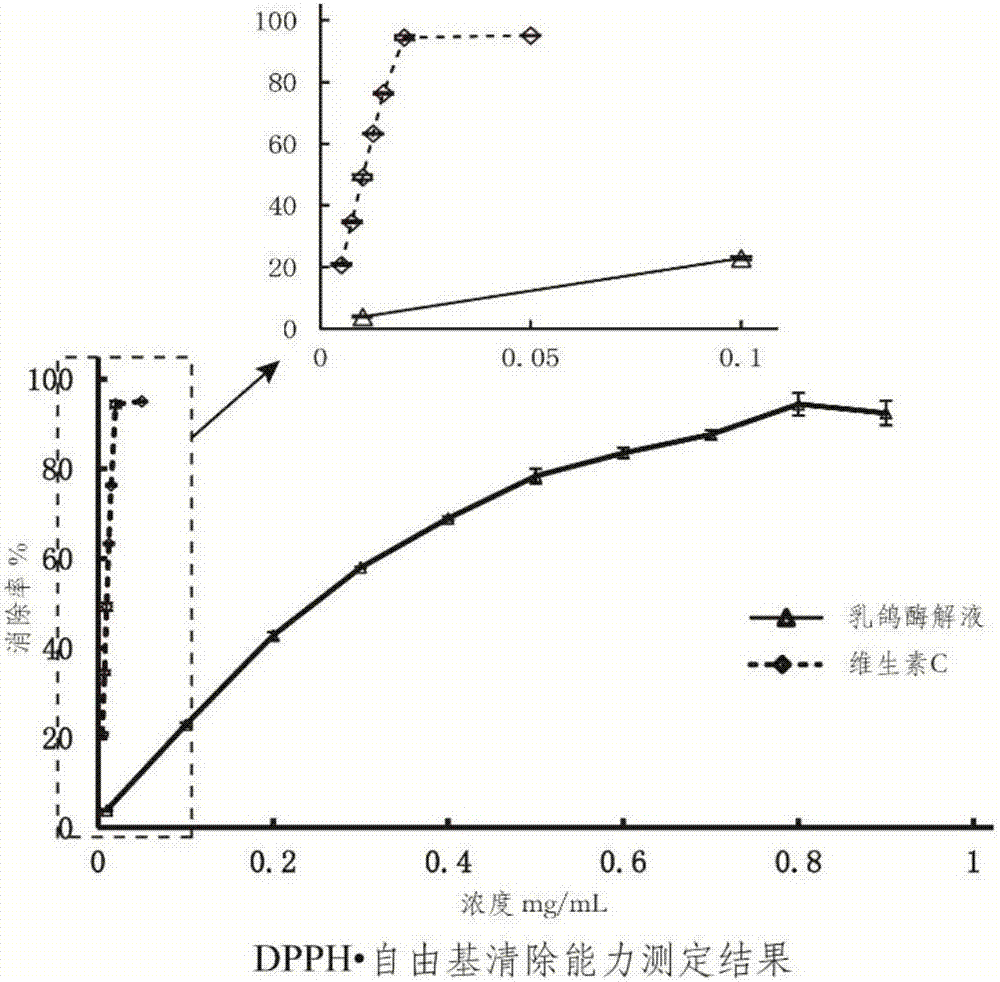

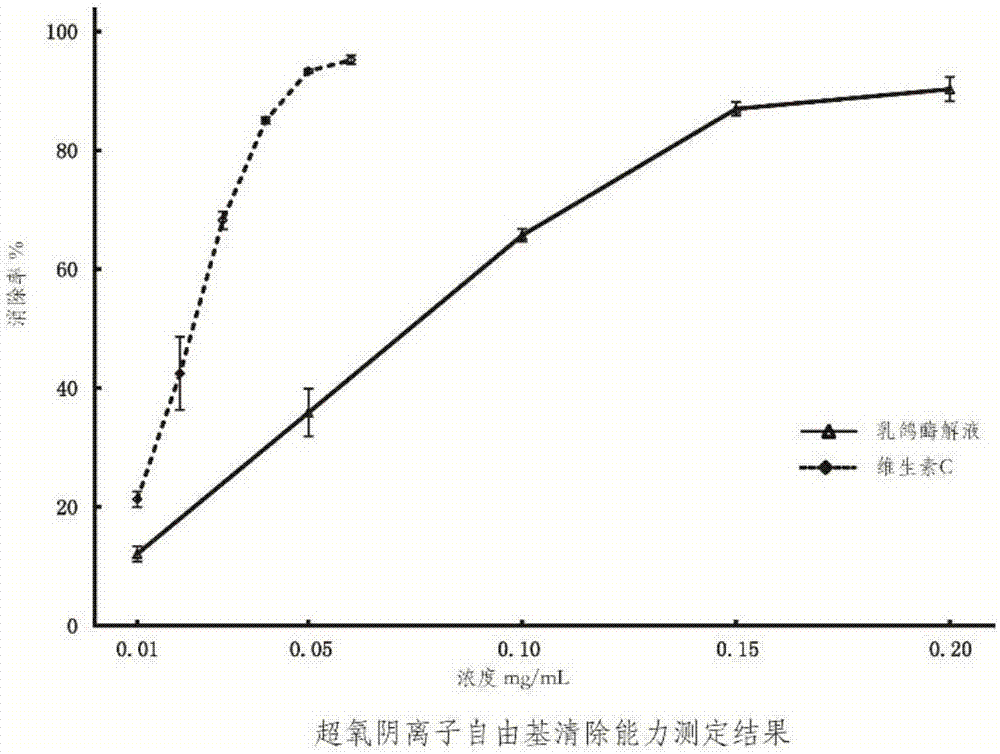

[0040] The obtained squab enzymatic solution was diluted in proportion, and its antioxidant capacity was tested, and compared with the antioxidant capacity of vitamin C. The data show that the squab enzymatic hydrolyzate has good antioxidant capacity, so it can be known that the squab amino acid oral liquid formulated with squab enzymatic hydrolyzate also has good antioxidant capacity.

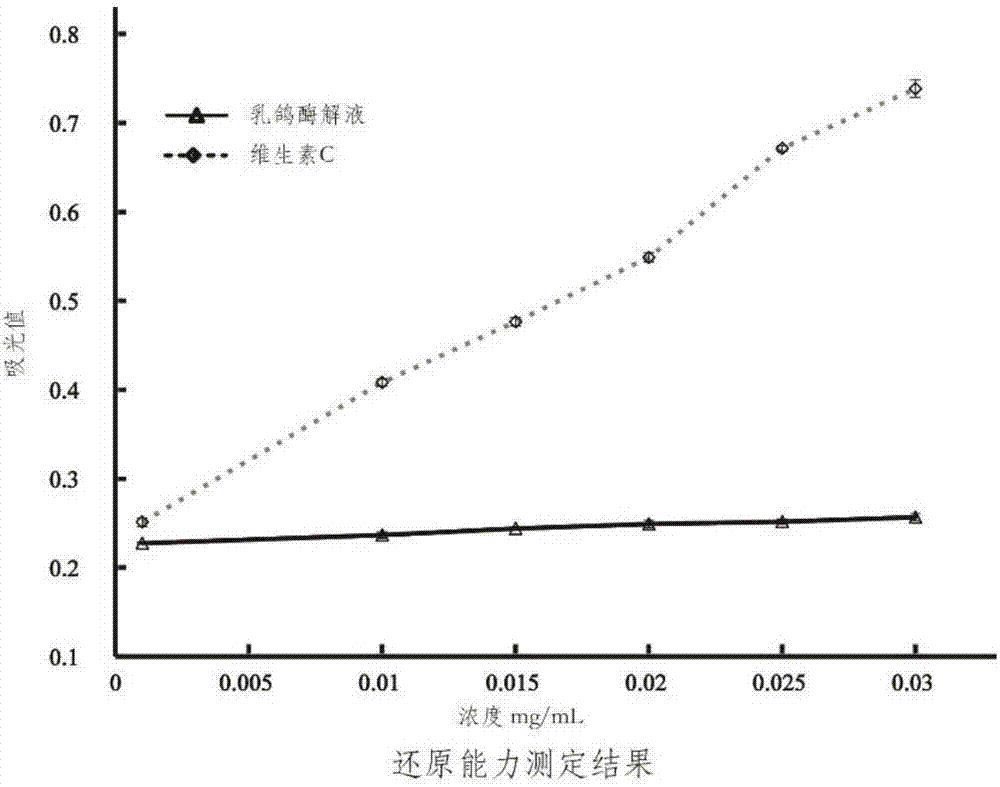

[0041] Taking vitamin C as the control, the reducing ability of the pigeon enzymatic solution was determined by the potassium ferricyanide reduction method. Determination of superoxide anion free radical (O2 - ) scavenging ability, adopt Fenton system OH Elimination method to measure the scavenging ability of squab enzymolyzate to hydroxyl radical (OH ), test result is as follows:

[0042] 1. The measurement result of reducing ability of squab enzymatic hydrolyzate (potassium ferricyanide reduction method)

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com