Method for treating printing waste gas

A waste gas and micro-bubble technology, applied in the field of waste gas, can solve the problems of improving air quality, reducing the quality of life of residents, and the irritating smell of waste gas, so as to prevent cholesterol and triglycerides, help gastrointestinal motility, The effect of speeding up metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for processing printing waste gas in this embodiment includes the following steps:

[0021] A: Pass water through the nano-bubble device to generate micro-bubbles with a diameter of 50-100 nanometers;

[0022] B: After the microbubbles pass through the negative ion oxygenation device, the microbubbles are negatively charged;

[0023] C: Negatively charged micro-bubbles are mixed evenly with exhaust gas, and the micro-bubbles are mixed with exhaust gas and exploded to form a local environment with high temperature above 4000K and high pressure above 40MPa. In this environment, water molecules are decomposed into -H and -OH radicals, -H And -OH radicals break the molecular bonds of organic compounds in the exhaust gas and lose their activity;

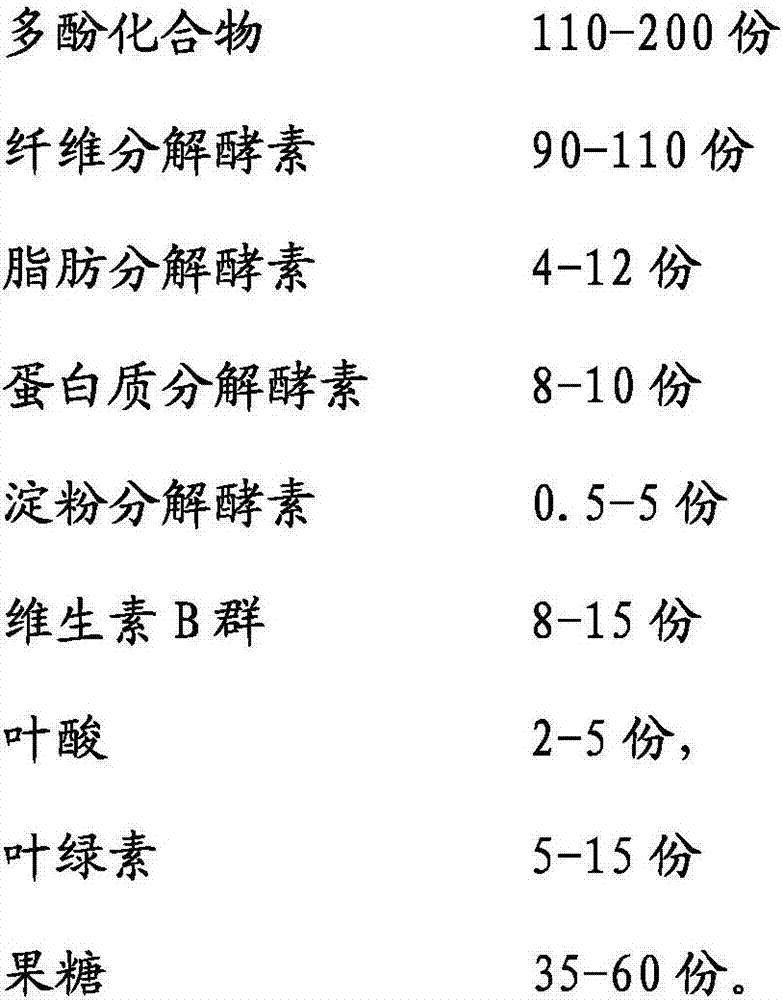

[0024] D: spraying biological deodorizing enzymes to exhaust gas; the biological deodorizing enzymes are composed of the following components by weight:

[0025]

[0026] The nano-scale microbubbles explode after mixi...

Embodiment 2

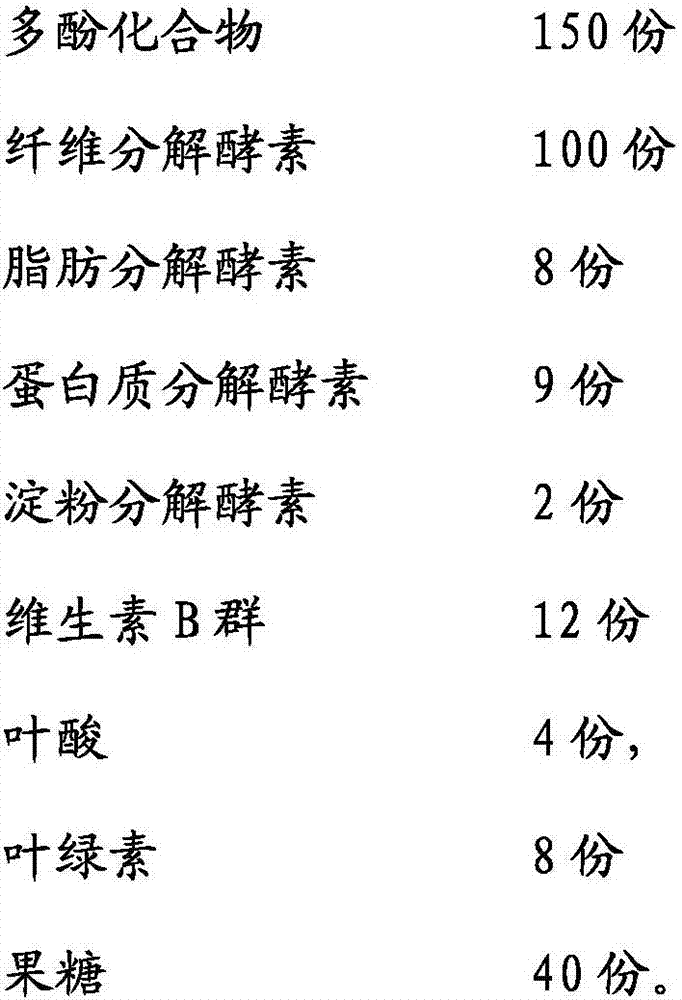

[0028] Step D biological deodorizing enzyme described in the present embodiment is made up of following components by weight:

[0029]

Embodiment 3

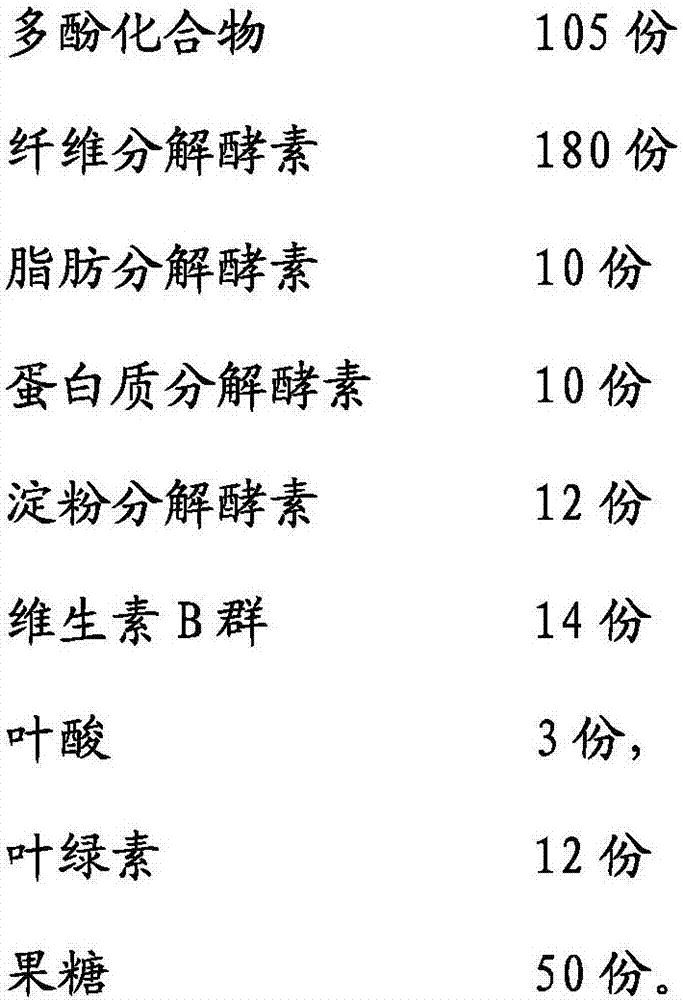

[0031] Step D biological deodorizing enzyme in the present embodiment is made up of following components by weight:

[0032]

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com