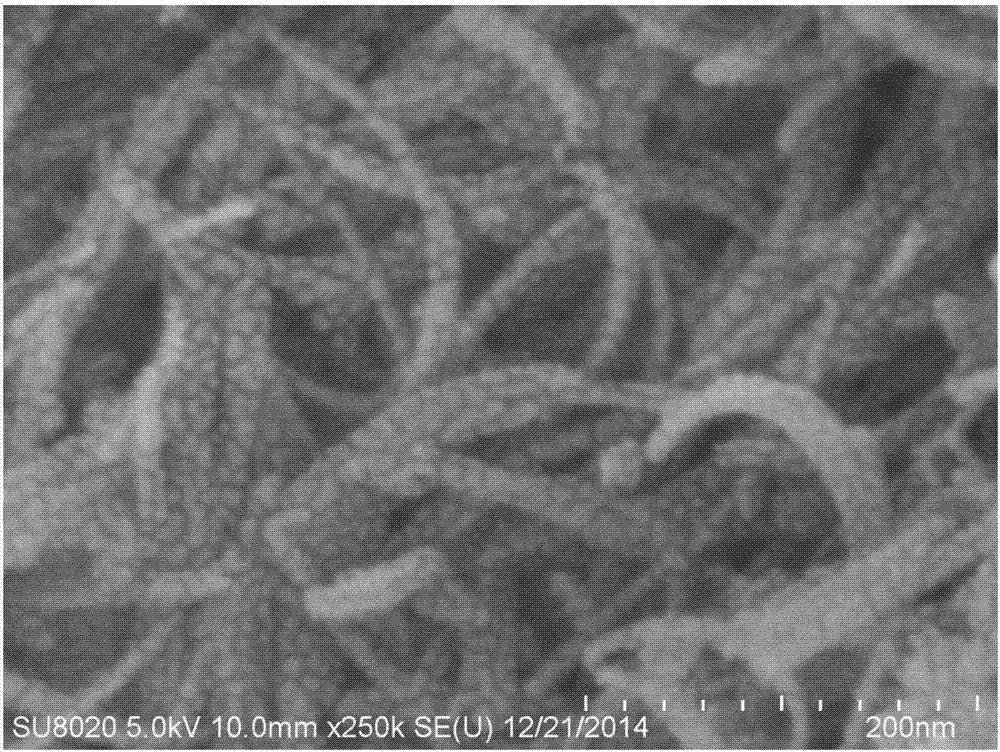

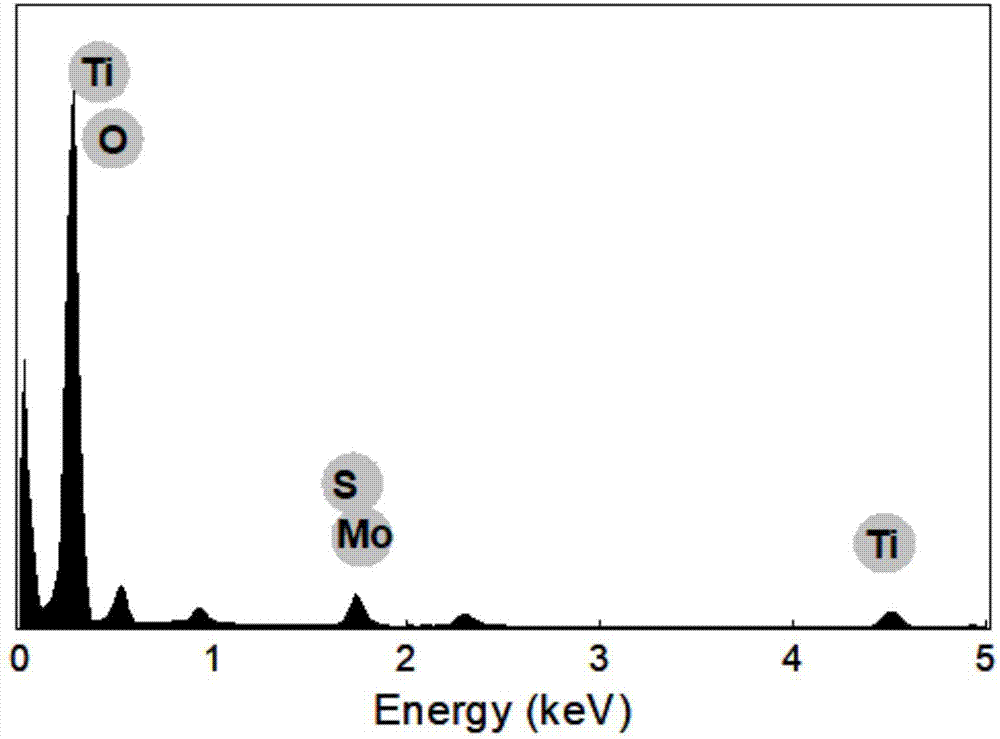

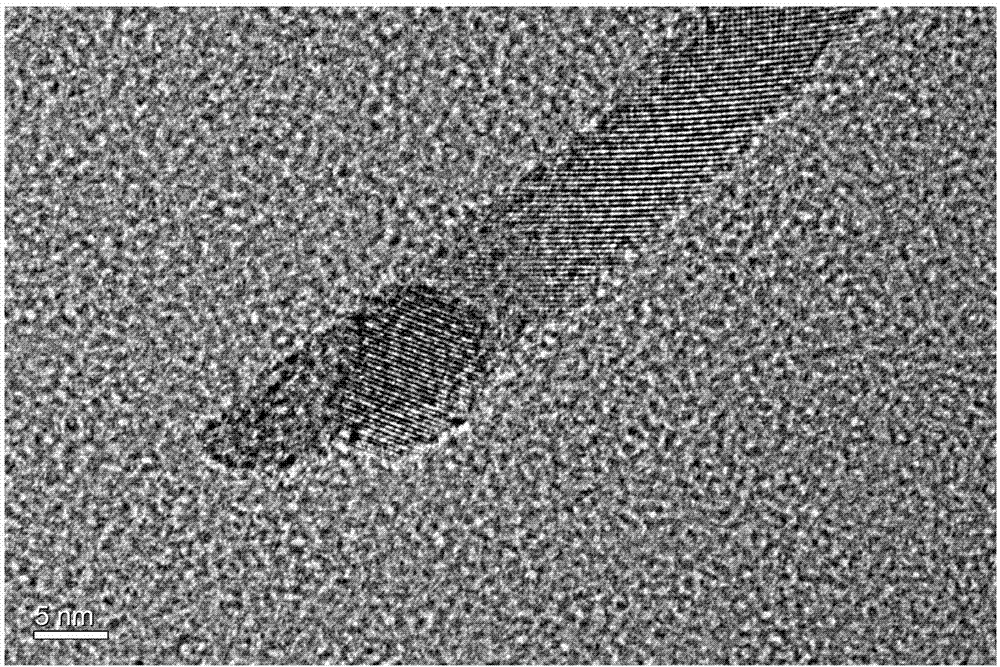

A molybdenum disulfide quantum dot/ultrafine titanium dioxide heterojunction nanoribbon photocatalyst and a preparing method and applications thereof

A technology of ultra-fine titanium dioxide and molybdenum disulfide, applied in the field of photocatalytic materials, can solve the problems of low photocatalyst efficiency, difficulty in wide application, high preparation cost, etc., achieve great application value, convenient and flexible application, and improve utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] ①Prepare the mixed organic solvent according to the volume ratio N,N-dimethylformamide: glacial acetic acid (DMF:HAc)=6:4, then mix the organic solvent, LiAc·2H 2 O, tetrabutyl titanate mixed organic solvent according to 100L, 2000g LiAc·2H 2 The proportion of 0.20L tetrabutyl titanate is added in the hydrothermal reaction kettle successively, and the filling degree is controlled at 60% of the reaction kettle volume, and stirred evenly; then the hydrothermal reaction kettle is sealed, and it is put into a drying box to make The hydrothermal temperature is controlled at 200°C, and the reaction time is controlled at 20h. After the reaction is completed, it is naturally cooled to room temperature. The product obtained is repeatedly washed with absolute ethanol until it is neutral, then suction filtered, and dried. The obtained white powder is ultrafine TiO 2 nanobelt;

[0025] ②Take the TiO obtained in step ① 2 Powder and dispersed in water, ultrasonically stirred for 30...

Embodiment 2

[0033] ① Make a mixed organic solvent with a volume ratio of DMF:HAc (N,N-dimethylformamide: glacial acetic acid) = 6:4, LiAc·2H 2 O, tetrabutyl titanate according to 120L mixed organic solvent, 2100g LiAc 2H 2 The ratio of 0.25L tetrabutyl titanate is added in the hydrothermal reaction kettle successively, and the filling degree is controlled at 50% of the reaction kettle volume, and stirred evenly; then the hydrothermal reaction kettle is sealed, and it is put into a drying box, so that The hydrothermal temperature is controlled at 200±10°C, and the reaction time is controlled at 16 hours. After the reaction is completed, it is naturally cooled to room temperature, and the obtained product is repeatedly washed with absolute ethanol to neutrality, then filtered with suction, and dried to obtain ultrafine TiO 2 Nanobelt white powder;

[0034] ②Take the TiO obtained in step ① 2 Powder and dispersed in water, ultrasonically stirred for 30±5min to obtain TiO with a concentratio...

Embodiment 3

[0038] ① Make a mixed organic solvent with a volume ratio of DMF:HAc (N,N-dimethylformamide: glacial acetic acid) = 6:4, LiAc·2H 2 O, tetrabutyl titanate mixed organic solvent according to 100L, 2000g LiAc·2H 2 The ratio of 0.20L tetrabutyl titanate is added in the hydrothermal reaction kettle successively, and the filling degree is controlled at 70% of the reaction kettle volume, and stirred evenly; then the hydrothermal reaction kettle is sealed, and it is put into a drying box to make The hydrothermal temperature is controlled at 200±10°C, and the reaction time is controlled at 18 hours. After the reaction is completed, it is naturally cooled to room temperature, and the obtained product is repeatedly washed with absolute ethanol until it is neutral, then suction filtered, and dried to obtain ultrafine TiO 2 Nanobelt white powder;

[0039] ②Take the TiO obtained in step ① 2 Powder and dispersed in water, ultrasonically stirred for 30±5min to obtain TiO with a concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com