Recovery method for salt crystals in brine refining mother liquor used for salt production

A recovery method and technology of refined halogen, applied in chemical instruments and methods, alkali metal halide, alkali metal halide purification and other directions, can solve the problems of waste of resources and wealth, waste, not considering the recovery of salt crystals, etc., to achieve removal capacity Strong, significant effect, stable process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

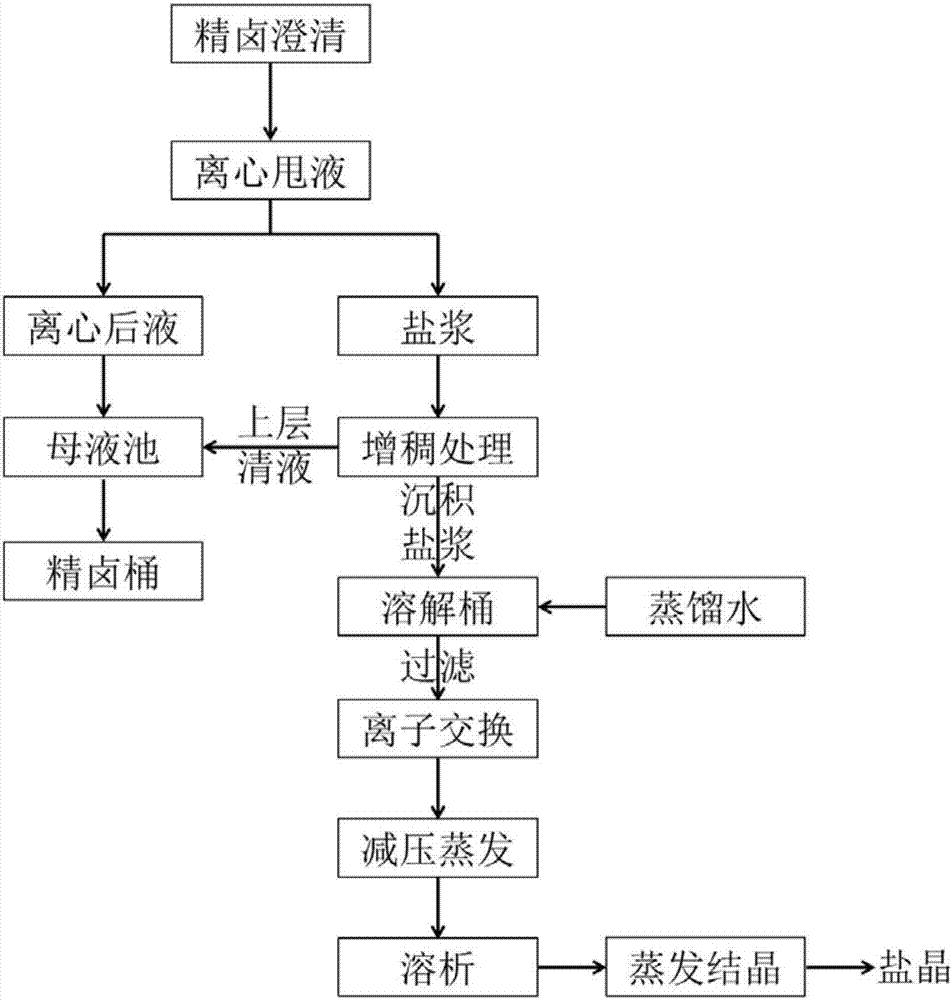

[0038] A method for recovering salt crystals from salt-making refined brine mother liquor, the steps of which are:

[0039] 1) After the clarification of raw brine, dosing reaction and refined brine clarification, mine salt brine enters the centrifuge to centrifuge the liquid. The salt slurry is pumped into the thickener by a salt slurry pump for thickening treatment. After thickening, the mass ratio of solid to liquid is 1:2.5;

[0040] 2) After thickening the salt slurry, let it stand for a period of ≥ 2 hours. After standing, the supernatant liquid of the salt slurry overflows into the mother liquor pool and mixes with the centrifuged liquid, and puts it into the brine bucket together, and deposits the liquid at the bottom. The salt slurry is pumped into the dissolution tank, and double distilled water is added to the dissolution tank to fully dissolve the soluble part in the salt slurry. In order to improve the dissolution rate, the dissolution tank is equipped with a stir...

Embodiment 2

[0049] A method for recovering salt crystals from salt-making refined brine mother liquor, the steps of which are:

[0050] 1) After the clarification of raw brine, dosing reaction and refined brine clarification, mine salt brine enters the centrifuge to centrifuge the liquid. The salt slurry is pumped into the thickener by a salt slurry pump for thickening treatment. After thickening, the mass ratio of solid to liquid is 1:2;

[0051] 2) After thickening the salt slurry, let it stand for a period of ≥ 2 hours. After standing, the supernatant liquid of the salt slurry overflows into the mother liquor pool and mixes with the centrifuged liquid, and puts it into the brine bucket together, and deposits the liquid at the bottom. The salt slurry is pumped into the dissolution tank, and double distilled water is added to the dissolution tank to fully dissolve the soluble part in the salt slurry. In order to improve the dissolution rate, the dissolution tank is equipped with a stirri...

Embodiment 3

[0060] A method for recovering salt crystals from salt-making refined brine mother liquor, the steps of which are:

[0061] 1) After the clarification of raw brine, dosing reaction and refined brine clarification, mine salt brine enters the centrifuge to centrifuge the liquid. The salt slurry is pumped into the thickener by a salt slurry pump for thickening treatment. After thickening, the mass ratio of solid to liquid is greater than 1:1.5;

[0062] 2) After thickening the salt slurry, let it stand for a period of ≥ 2 hours. After standing, the supernatant liquid of the salt slurry overflows into the mother liquor pool and mixes with the centrifuged liquid, and puts it into the brine bucket together, and deposits the liquid at the bottom. The salt slurry is pumped into the dissolution tank, and double distilled water is added to the dissolution tank to fully dissolve the soluble part in the salt slurry. In order to improve the dissolution rate, the dissolution tank is equippe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com