Bagged fertilizer

A bag-packing and bag-body technology, applied in the production field of slow-release fertilizers and fertilizers, can solve the problems of poor control intelligence, inability to use large-scale use, poor effect, etc., and is suitable for large-scale industrial production and promotion, with remarkable fertilizer efficiency Long-lasting, low-cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

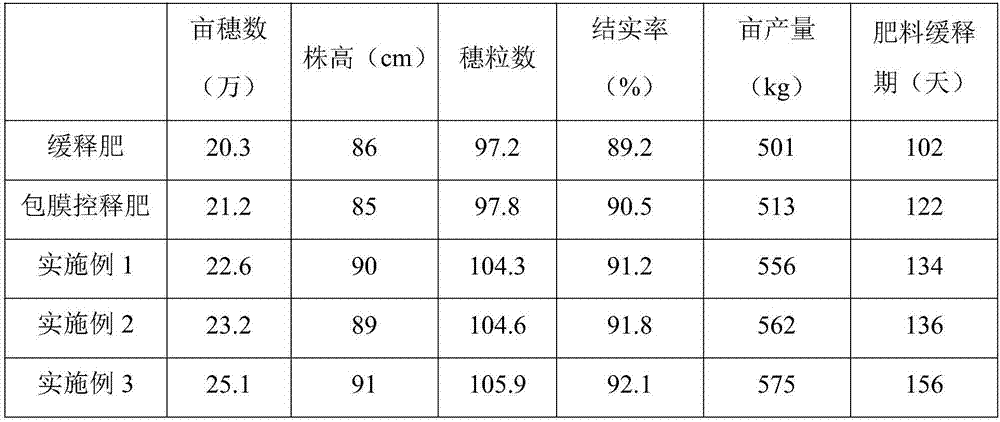

Examples

Embodiment 1

[0049] The concrete steps of the production and application of bagged fertilizer of the present invention are:

[0050] Step 1. Grind corn stalks to 100 mesh, mix them with polyhydroxyalkanoate at a ratio of 1:2, and make a bag.

[0051] Step 2. After the experiment, animal wastes such as animal carcasses are crushed, put into a fermentation machine and fermented for 4 days to obtain finished animal protein products, wherein 0.05 kg of fertilizer starter is added to every 1 kg of animal wastes during the fermentation process.

[0052] Step 3. Put 25 decomposed cow dung, 15 decomposed pig manure, 10 rice straw, 7 soybean cakes, 12 alfalfa, 15 amorpha, 12 lignite, 8 peanut meal, 10 kitchen waste, 8 vetch, 25 humic acid, and river Bottom mud 25, animal waste 15, NPK fertilizer 10, mixed trace elements 2 and traditional Chinese medicine composition 4 are uniformly mixed and granulated to obtain fertilizer granules.

[0053] Wherein, the trace elements include the following compon...

Embodiment 2

[0058] The concrete steps of the production and application of bagged fertilizer of the present invention are:

[0059] Step 1. Grind corn stalks to 100 mesh, mix them with polyhydroxyalkanoate at a ratio of 1:2, and make a bag.

[0060] Step 2. After the experiment, animal wastes such as animal carcasses are crushed, put into a fermenter and fermented for 5 days to obtain finished animal protein products, wherein 0.05 kg of fertilizer starter is added to every 1 kg of animal wastes during the fermentation process.

[0061] Step 3. Put 25 decomposed cow dung, 15 decomposed pig manure, 10 rice straw, 7 soybean cakes, 12 alfalfa, 15 amorpha, 12 lignite, 8 peanut meal, 10 kitchen waste, 8 vetch, 25 humic acid, and river Bottom sludge 25, animal waste 15, nitrogen, phosphorus and potassium fertilizer 10, mixed trace elements 2, traditional Chinese medicine composition 4, and mixed bacterial powder 0.006 were uniformly mixed and granulated to obtain fertilizer granules.

[0062] W...

Embodiment 3

[0068] The concrete steps of the production and application of bagged fertilizer of the present invention are:

[0069] Step 1. Grind corn stalks to 90 mesh, mix them with polyhydroxyalkanoate at a ratio of 1:2 to make a bag, and add 0.5 parts by weight of Chinese medicine extract, which consists of the following parts by weight Extracted from traditional Chinese medicine: Pulsatilla 15, Dandelion 28, Prunella vulgaris 12, Guanzhong 10, Shatang 25 and Plantain 18.

[0070] Step 2. After the experiment, the animal wastes such as animal carcasses are crushed, put into a fermenter and fermented for 3 days to obtain finished animal protein products, wherein 0.05 kg of fertilizer starter is added to every 1 kg of animal wastes during the fermentation process.

[0071] Step 3. Put 20 decomposed cow dung, 18 decomposed pig manure, 12 rice straw, 8 soybean cake, 14 alfalfa, 16 amorpha japonica, 13 lignite, 9 peanut meal, 12 kitchen waste, 9 vetch, 28 humic acid, and river Bottom slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com