Hetero-metal iodide framework materials and preparation method thereof

A framework material, iodide technology, applied in organic chemistry methods, lead organic compounds, organic chemistry and other directions, to achieve the effects of novel structure, simple preparation process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, 0.380g of cuprous iodide, 0.456g of lead iodide, 0.022g of TPT, 0.08mL of hydroiodic acid (45%), and 5mL of methanol were added to a stainless steel reaction kettle lined with 10mL of polytetrafluoroethylene, sealed and stirred Two hours later, take out the stirring magnet, seal the stainless steel reaction kettle with the reaction liquid, and crystallize it in an oven at 160°C for 7 days. The crystals generated in the kettle were removed and washed repeatedly 5 times with deionized water, and dried at room temperature to obtain black block crystals of Pb 5 Cu 2 I 16 (Me 2 TPT) 2 .

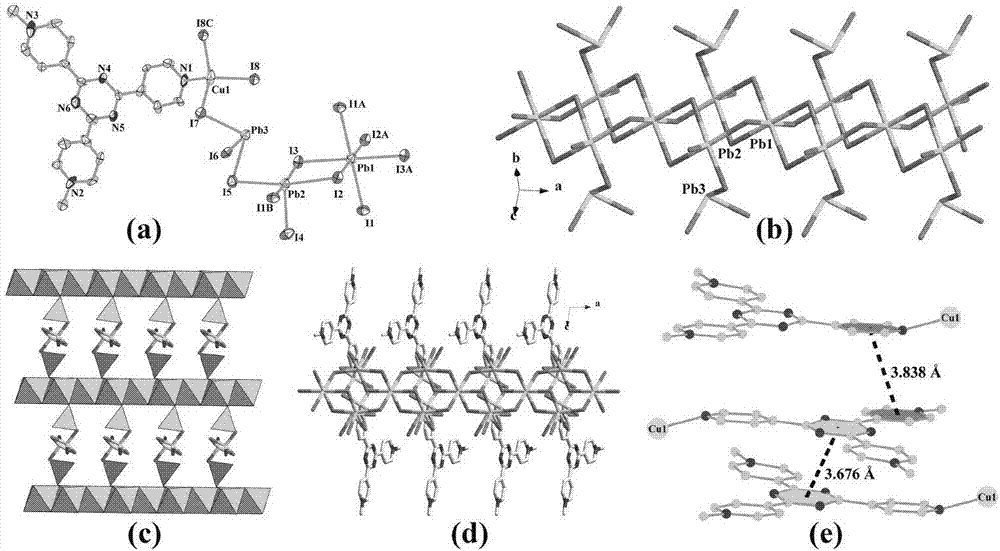

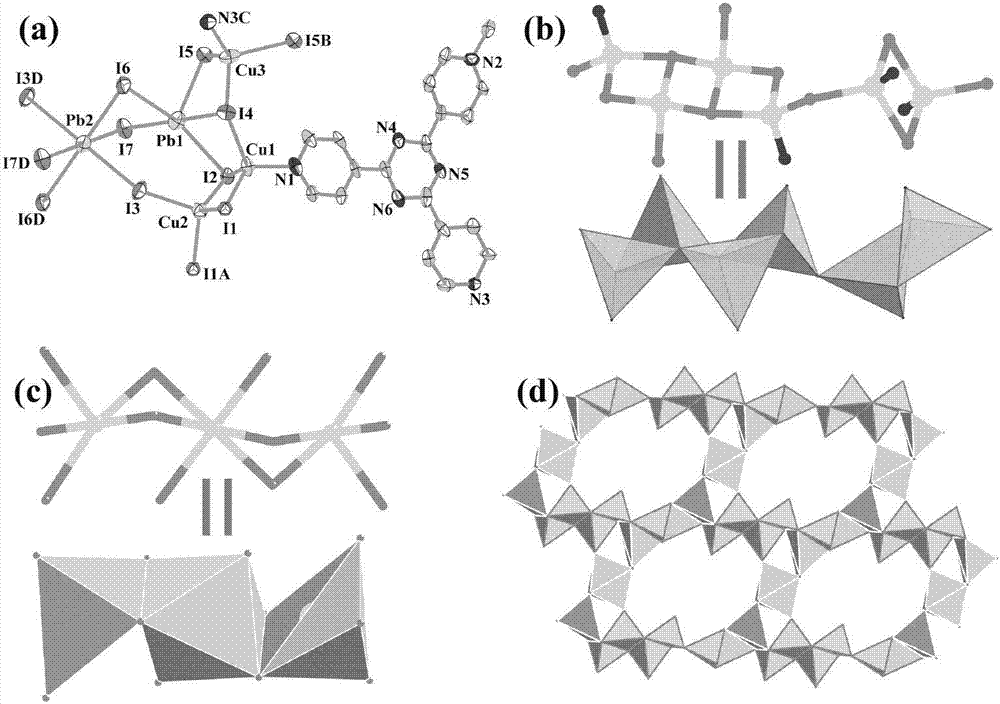

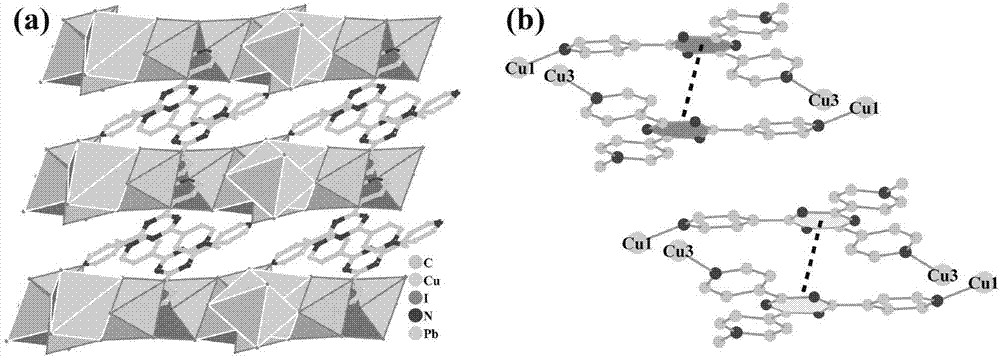

[0039] In this example, single crystal diffraction was performed on the prepared black blocky crystals, and the data analysis showed that the obtained complexes had a three-dimensional framework structure, wherein the iodide ions took the form of μ 2 and μ 3 The pattern bridges Cu(I) and Pb(II) to form a two-dimensional inorganic subunit layer, in which the two-dim...

Embodiment 2

[0041] In this embodiment, 0.380g of cuprous iodide, 0.472g of lead iodide, 0.022g of TPT, 0.10mL of hydroiodic acid (45%) and 6mL of methanol were added to a 10mL polytetrafluoroethylene-lined stainless steel reaction kettle, sealed and stirred After two hours, take out the stirring magnet, then seal the stainless steel reaction kettle with the reaction solution, and crystallize it in an oven at 160°C for 8 days. After the reaction is completed, take out the stainless steel reaction kettle and let it cool naturally at room temperature. The crystals generated within were removed and washed repeatedly 5 times with deionized water, and dried at room temperature to obtain black block crystals. After cooling, filtering, washing and drying methods as in Example 1, the various characterizations, results and implementation of the target product were obtained. Example 1 is the same.

Embodiment 3

[0043] In this embodiment, 0.389g of cuprous iodide, 0.460g of lead iodide, 0.020g of TPT, 0.14mL of hydroiodic acid (45%) and 5mL of methanol were added to a 10mL polytetrafluoroethylene-lined stainless steel reaction kettle, sealed and stirred After two hours, take out the stirring magnet, then seal the stainless steel reaction kettle with the reaction solution, and crystallize it in an oven at 160°C for 7 days. After the reaction is completed, take out the stainless steel reaction kettle and let it cool naturally at room temperature. The crystals generated within were removed and washed repeatedly 5 times with deionized water, and dried at room temperature to obtain black block crystals. After cooling, filtering, washing and drying methods as in Example 1, the various characterizations, results and implementation of the target product were obtained. Example 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com