Preparation method and application of nano copper-zinc compound antibacterial material

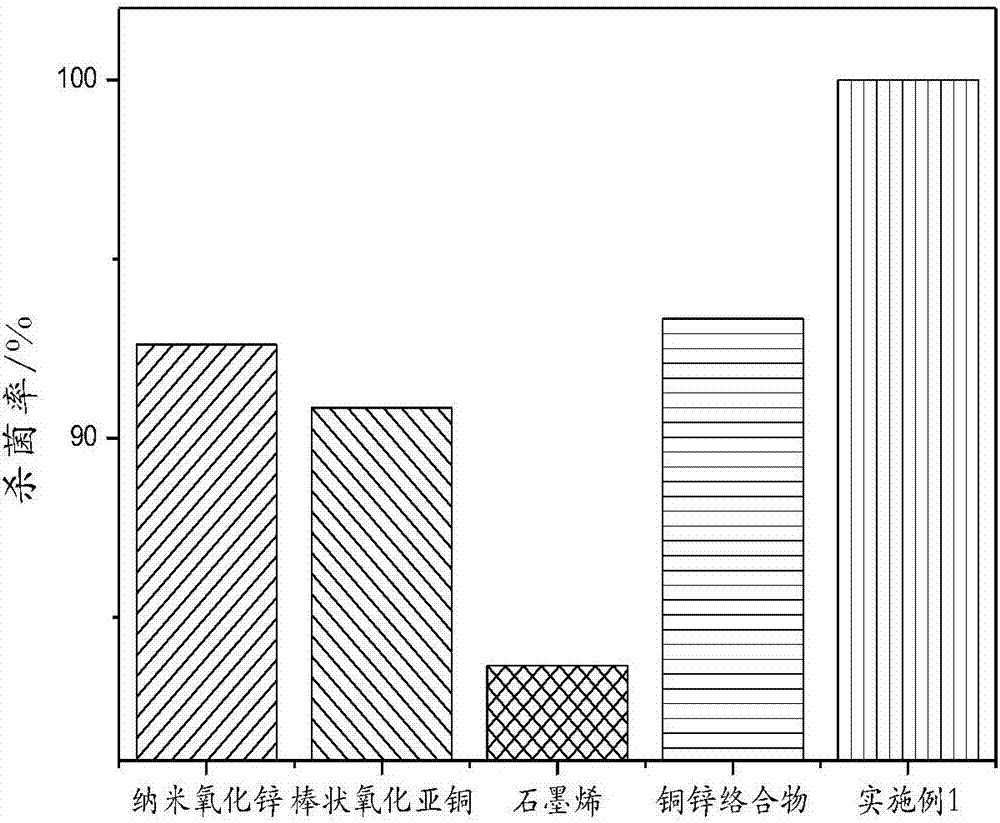

A composite antibacterial and nano-copper technology, applied in the field of environmental engineering, can solve the problems of incapable of high bactericidal effect, unsatisfactory bactericidal effect, single metal particles, etc., and achieves the effects of long antibacterial cycle, good antibacterial performance and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

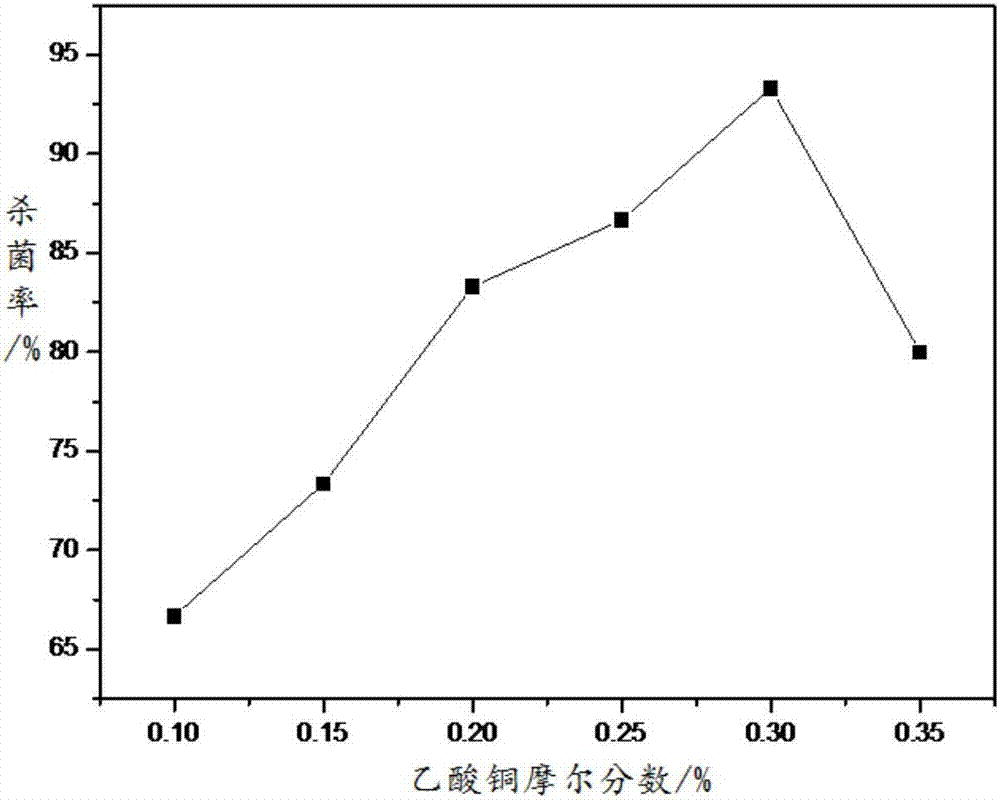

[0033] An embodiment of the present invention provides a method for preparing a nano-copper-zinc composite antibacterial material, which specifically includes the following steps:

[0034] S1: Dissolve the zinc salt and copper salt in water to form a copper-zinc solution, add an equal volume of absolute ethanol to the copper-zinc solution, and perform ultrasonic treatment to obtain solution I.

[0035] In this step, water-soluble zinc salt and copper salt are selected to form a copper-zinc mixed solution, and then a polar solvent is added to dissolve, which is beneficial to the high dispersion of copper-zinc in the solvent and prepares for the next complexation reaction.

[0036] S2: Adjust the pH of solution I to 5.5-6.7, add citric acid monohydrate, stir, and sonicate until there is no flocculation in the solution to obtain solution II.

[0037] In this step, citric acid monohydrate is selected as a complexing agent, which can effectively complex zinc ions and copper ions, s...

Embodiment 1

[0056] Preparation of nano-copper-zinc composite antibacterial material:

[0057] Dissolve 0.35mol of zinc acetate and 0.15mol of copper acetate in 500ml of water to form a copper-zinc solution, add 50ml of absolute ethanol, and sonicate for 0.5h to obtain solution I;

[0058] Adjust the pH of solution I to 6.0, add 0.6 mol of citric acid monohydrate, stir, 40kHz ultrasonic treatment for 0.75h until there is no flocculation in the solution, and obtain solution II;

[0059] Heat the solution II in an 80°C water bath, stir, and centrifuge to obtain a precipitate. The precipitate is washed with absolute ethanol for 3-5 times and then dried in an oven at 80°C for 24-48h. After drying, it is ground into a powder, and the powder is calcined in a muffle furnace at 500°C for 2h. Cooling to obtain copper-zinc complex;

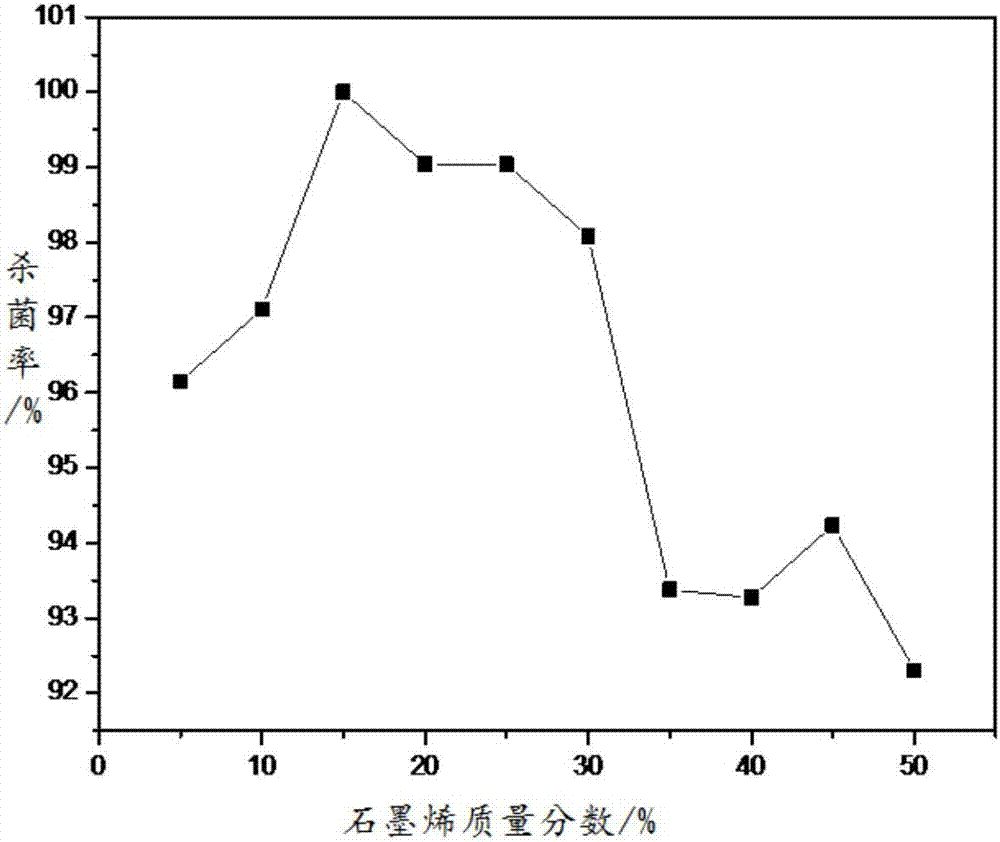

[0060] Mix 0.85g of copper-zinc complex and 0.15g of graphene in 80ml of N,N-dimethylacetamide solution, and ultrasonically treat it for 6 hours to obtain solution III...

Embodiment 2

[0065] Preparation of nano-copper-zinc composite antibacterial material:

[0066] Dissolve 0.67mol of zinc acetate and 0.33mol of copper acetate in 750ml of water to form a copper-zinc solution, add 75ml of absolute ethanol, and sonicate for 0.2h to obtain solution I;

[0067] Adjust the pH of solution I to 5.5, add 1 mol of citric acid monohydrate, stir, 30kHz ultrasonic treatment for 0.5h until there is no flocculation in the solution, and obtain solution II;

[0068] Heat the solution II in a 70°C water bath, stir, and centrifuge to obtain a precipitate. The precipitate is washed with absolute ethanol for 3-5 times and then dried in an oven at 80°C for 24-48h. After drying, it is ground into a powder, and the powder is calcined in a muffle furnace at 480°C for 3h. Cooling to obtain copper-zinc complex;

[0069] Mix 0.6g of copper-zinc complex and 0.2g of graphene in 40ml of N,N-dimethylacetamide solution, and ultrasonically treat for 5h to obtain solution III;

[0070] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com