Copper-based composite material heat sink with graphite sheet oriented layered arrangement and preparation method thereof

A technology of copper-based composite materials and graphite flakes, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of difficult electrical machining and cutting of materials, poor directional thermal conductivity, and low orientation ratio of graphite flakes, etc., and achieves simple and easy operation methods Easy to cut by electrical machining, and improve the effect of anisotropic thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

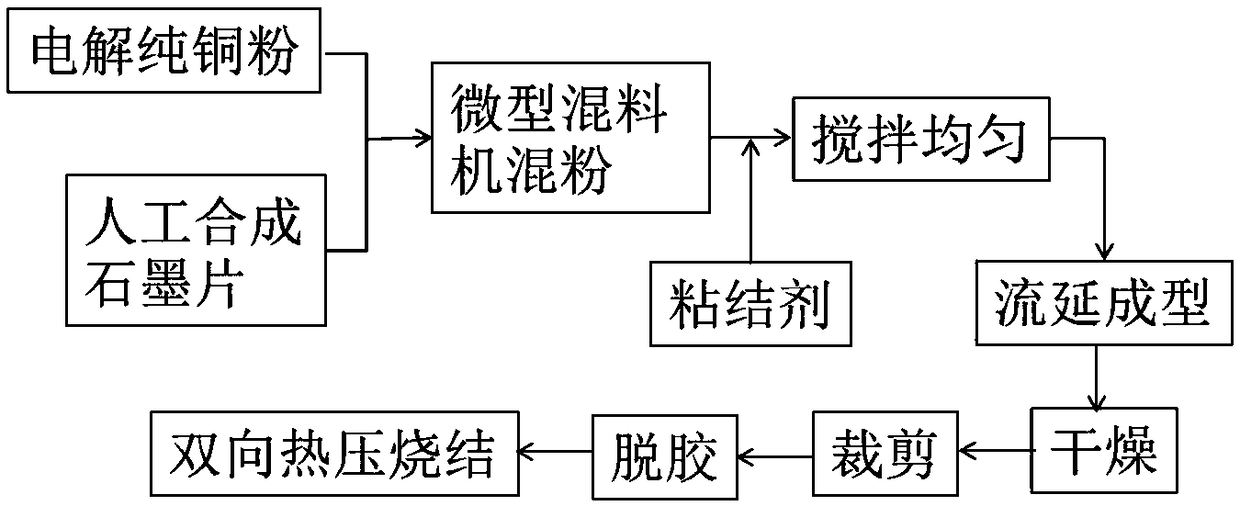

[0028] A high thermal conductivity electronic packaging composite material substrate, the raw material mixed powder is composed of 5-10μm electrolytic copper powder and 1-2mm diameter, 20-50μm thick synthetic graphite sheet, the volume fraction of pure copper powder and graphite sheet is respectively 60% and 40%.

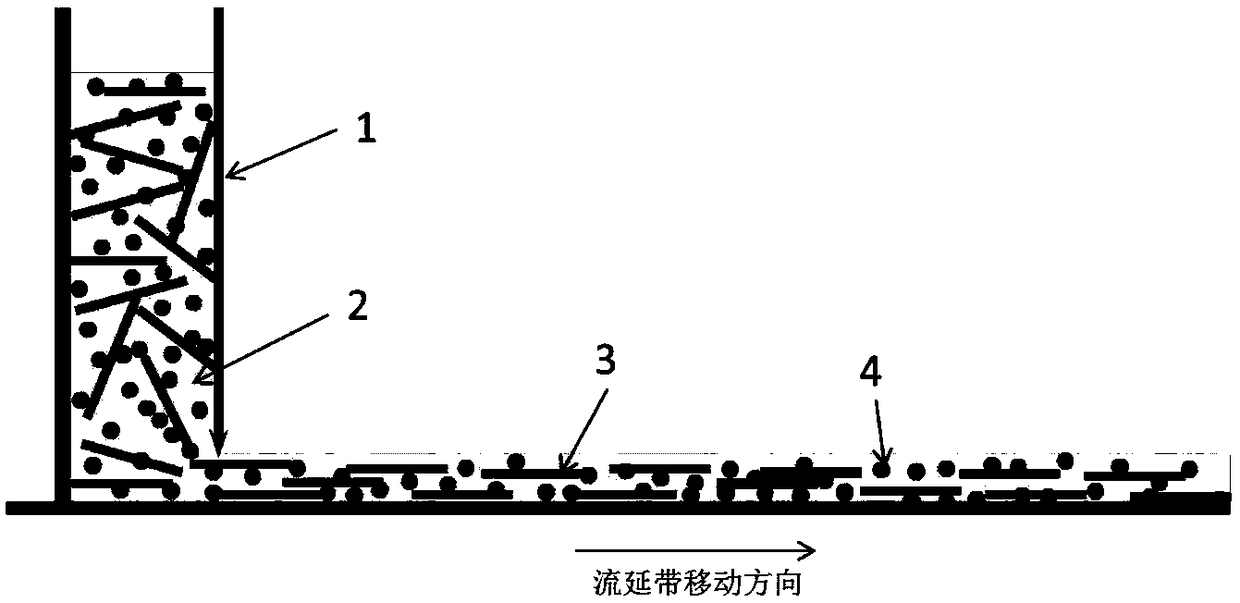

[0029] Mix the above-mentioned components in proportion, mix them in a micro mixer for 9 hours to form a uniform powder, add a binder with a mass ratio of polyvinyl butyral to ethanol of 1:9, and fully stir to form a uniform slurry. The slurry was poured into the casting device and cast into a film. After degumming at 400°C for 2 hours, the temperature was raised at 5°C / min to 1000°C during hot-pressing sintering, and the temperature was raised to 1000°C for bidirectional pressure sintering. Copper-based electronic packaging composites. The thermal conductivity along the direction parallel to the graphite sheet reaches 500w / m·k.

Embodiment 2

[0031] A high thermal conductivity electronic packaging composite material substrate, the raw material mixed powder is composed of 5-10μm electrolytic copper powder and 1-2mm diameter, 20-50μm thick synthetic graphite sheet, the volume fraction of pure copper powder and graphite sheet is respectively 50% and 50%.

[0032] Mix the above-mentioned components in proportion, mix them in a micro mixer for 9 hours to form a uniform powder, add a binder with a mass ratio of polyvinyl butyral to ethanol of 1:9, and fully stir to form a uniform slurry. The slurry was poured into a casting device and cast into a film. After degumming at 400°C for 2 hours, the temperature was raised at 5°C / min to 1000°C during hot pressing and sintering with bidirectional pressure and sintering, and the temperature was kept for 10 minutes. Copper-based electronic packaging composites. The thermal conductivity along the direction parallel to the graphite sheet reaches 550w / m·k.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| crush indicators | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com