Device and method for treating refractory pollutants through electrocatalytic oxidation

An electrocatalytic oxidation and refractory technology, which is used in oxidation water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problem of low ozone yield and utilization rate, restricting the development of Fenton method, and high treatment costs. problems, to achieve the effect of high production rate and utilization rate, complete degradation of organic matter, and simple reaction device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

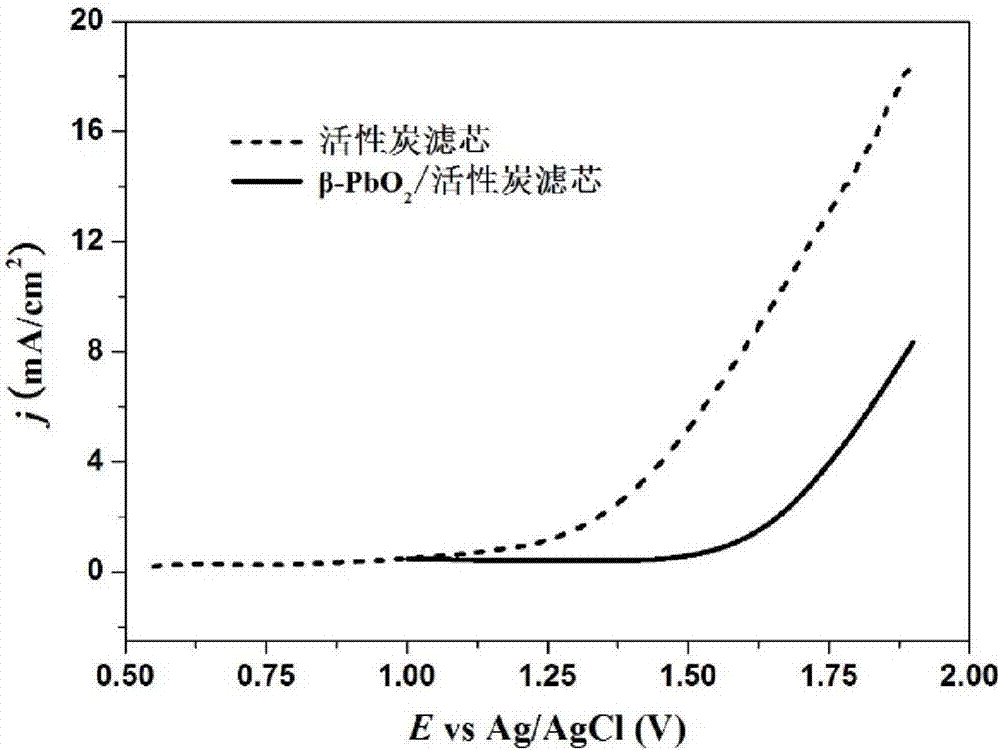

[0040] β-PbO proposed by the present invention 2 / Activated carbon anode electrocatalytic oxidation process is aimed at refractory organic pollutants, so this embodiment selects the concentrated water of low-pressure nanofiltration after the biological treatment process (referred to as NF concentrated water) as the treatment target, and takes NF concentrated water from a water plant in Beijing. The water quality indicators are shown in Table 1.

[0041] Table 1 Analysis table of NF concentrated water quality of a water plant in Beijing

[0042]

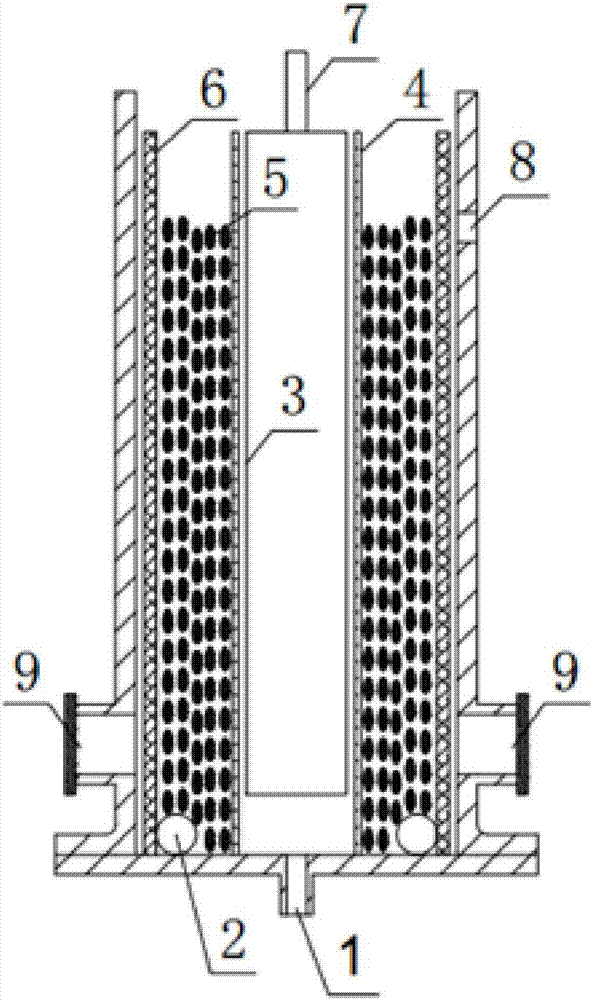

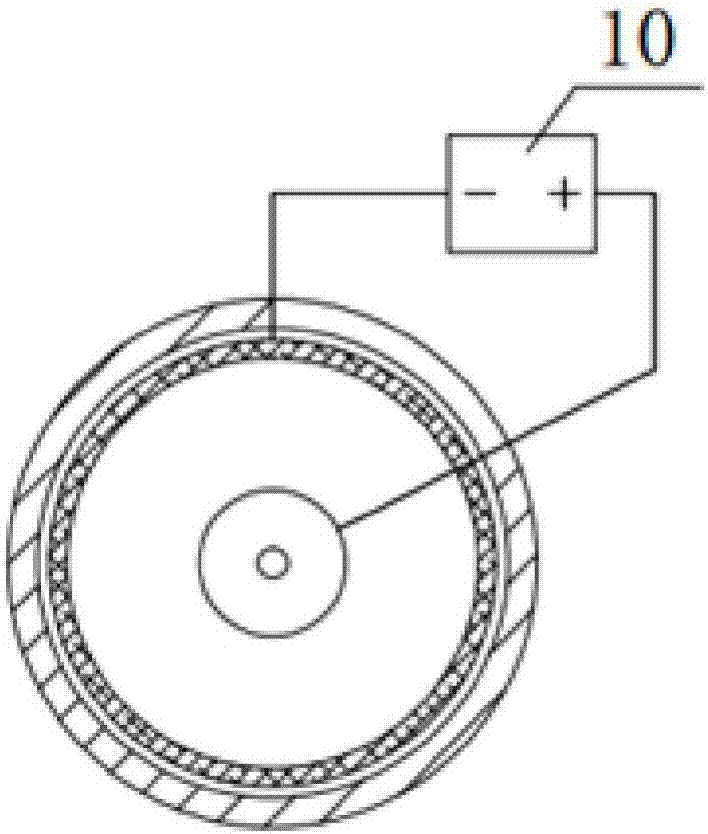

[0043] Electrocatalytic devices used such as figure 1 as shown, figure 1 It shows a schematic structural diagram of a device for electrocatalytic oxidation treatment of refractory pollutants according to an embodiment of the present invention, figure 2 for figure 1 A cross-sectional view of the device. The reaction device of the device for electrocatalytic oxidation treatment of refractory pollutants includes a cylindrical sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com