Enhanced biological phosphorus removal method

A technology for biological phosphorus removal and water inflow, which is applied in chemical instruments and methods, biological water/sewage treatment, water pollutants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1) The reactor is built using SBR reactor. The reactor is cylindrical, with a bottom diameter of 400cm, a height of 1200cm, and an effective volume of 125L. It runs in the order of water intake, dark stirring, light stirring, light aeration, precipitation, drainage, and idleness. ; Idle time is 0-0.5h, set according to needs;

[0047] 2) Inoculate sludge, inoculate activated sludge in A2 / O process aeration tank, after sludge inoculation, when the SBR reactor is at the highest water level, the sludge concentration in the system is 4.95g / L;

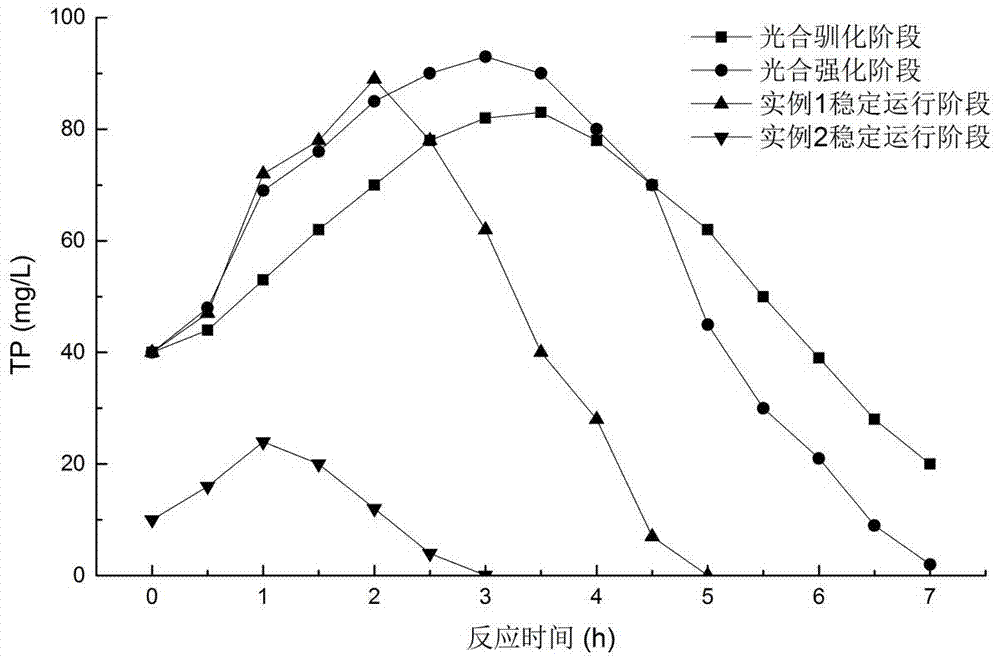

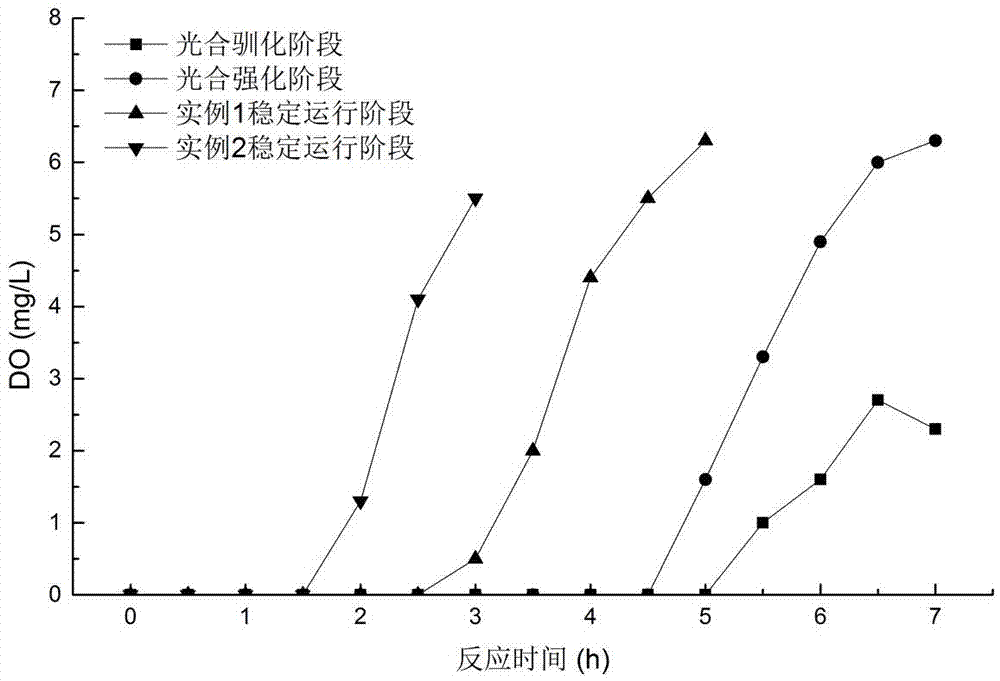

[0048] 3) In the photosynthetic acclimation stage, use tap water to add sodium phosphate and sodium acetate to mix water so that the influent TP is 40mg / L, the influent volatile fatty acid is 420mg / L, and the influent volatile fatty acid / TP=10.05> 10; According to step 1) sequence operation, each cycle is 8h, including 3h dark stirring, light stirring 2h, light aeration 2h, sedimentation 45min, the rest of the time is water intake, drainag...

Embodiment 2

[0052] Step 1)-4) Same as Example 1;

[0053] 5) In the sewage treatment stage, domestic sewage is used, the influent TP is 10mg / L, the influent COD is 200mg / L, and the influent COD / TP=20> 6. Influent alkalinity is 100mg / L, influent alkalinity / TP=2.5> 2; Adopt SBR reactor, run in the order of water intake, dark stirring, light stirring, precipitation, drainage, and idle, without aeration; dark stirring time 1h; when light stirring, the illumination is 3000lux / m 2 ; The age of the sludge in the control system is 10d; the light is stirred until TP in the system <0.1mg / L, stop stirring, settling for 30min, drain water, enter the next cycle after being idle, repeat this mode of operation; after 5d, the light stirring time is reduced from 4h to 2h, and then the fixed light stirring time is 2h (cycle time Is 3h). The maximum TP concentration in the system during the dark stirring stage is 24mg / L, which is 2.4 times the initial TP concentration of the system, indicating a good anaerobic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com