Thermoplastic polyurethane elastomer with high barrier property and preparation method thereof

A thermoplastic polyurethane and elastomer technology, applied in the field of barrier thermoplastic polyurethane elastomer and its preparation, high barrier performance thermoplastic polyurethane elastomer and its preparation, can solve the problem that the barrier performance is not enough to meet the barrier performance, etc., to reduce the free volume, Effect of prolonged time and high barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

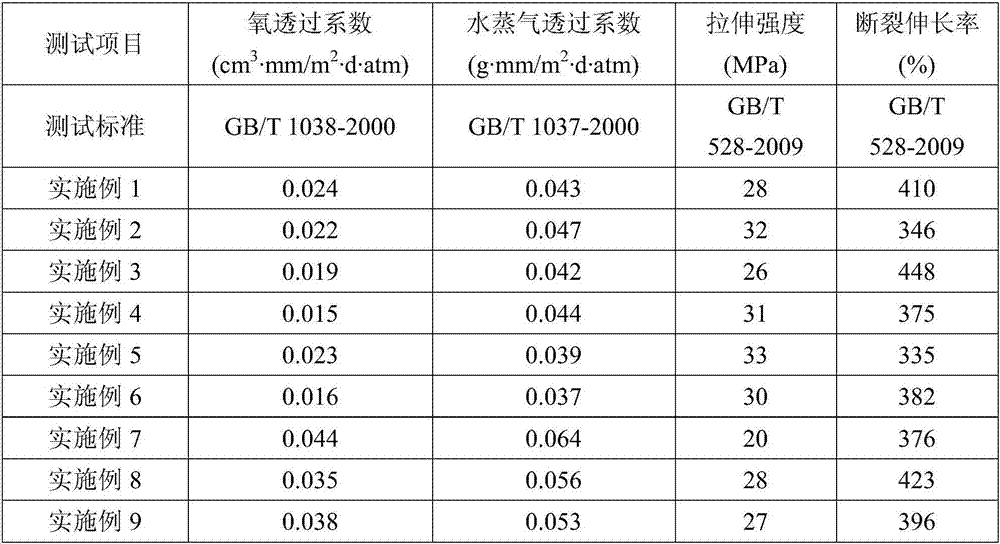

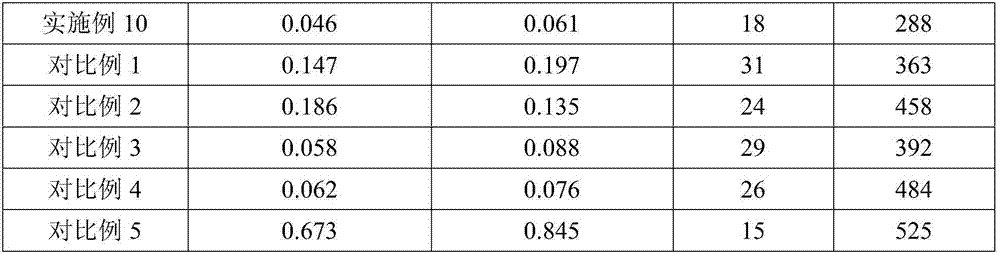

Examples

Embodiment 1

[0055] A barrier thermoplastic polyurethane elastomer, its raw material includes the following components in parts by mass:

[0056] 50 parts of diisocyanate (35 parts of 1,3-XDI and 15 parts of 1,3-H6XDI), 50 parts of oligomer polyol (25 parts of PEC and 25 parts of EVOH), 15 parts of chain extender (0.75 parts of isophthalic Methylamine, 1.5 parts of trimethylolpropane and 12.75 parts of 1,4-butanediol), 2 parts of layered silicate (montmorillonite), 0.5 parts of silane coupling agent (KH540) and catalyst (dilauric acid Dibutyltin) 0.1 part;

[0057] The number average molecular weight of PEC is 800, and the hydroxyl value is 50 mgKOH / g; the number average molecular weight of EVOH is 1000, and the molar percentage of vinyl alcohol units is 50 mol%.

[0058] The preparation method of above-mentioned barrier thermoplastic polyurethane elastomer comprises the steps:

[0059] (1) carry out drying treatment to diisocyanate, polyether polyol and chain extender;

[0060] (2) Add...

Embodiment 2

[0063] A barrier thermoplastic polyurethane elastomer, its raw material includes the following components in parts by mass:

[0064] 20 parts of diisocyanate (17 parts of 1,3-XDI and 3 parts of 1,3-H6XDI), 80 parts of oligomer polyol (15 parts of PPC and 65 parts of EVOH), 5 parts of chain extender (0.25 parts of Methylamine, 1 part of trimethylolpropane and 3.75 parts of 1,3-propanediol), 8 parts of layered silicate (kaolin), 2 parts of silane coupling agent (IPTS) and 1 part of catalyst (stannous octoate);

[0065] The number average molecular weight of PEC is 3000, and the hydroxyl value is 20 mgKOH / g; the number average molecular weight of EVOH is 800, and the molar percentage of vinyl alcohol units is 30 mol%.

[0066] The preparation method of above-mentioned barrier thermoplastic polyurethane elastomer comprises the steps:

[0067] (1) carry out drying treatment to diisocyanate, polyether polyol and chain extender;

[0068] (2) Add the dry formulation amount of diisoc...

Embodiment 3

[0071] A barrier thermoplastic polyurethane elastomer, its raw material includes the following components in parts by mass:

[0072] 30 parts of diisocyanate (24 parts of 1,3-XDI and 6 parts of 1,3-H6XDI), 70 parts of oligomer polyol (14 parts of PEC and 56 parts of EVOH), 10 parts of chain extender (0.1 Methylamine, 1.5 parts of trimethylolpropane and 8.4 parts of 1,6-hexanediol), 5 parts of layered silicate (mica), 1 part of silane coupling agent (KH560) and catalyst (dibutyltin dilaurate )0.5 copies;

[0073] The number average molecular weight of PEC is 2000, and the hydroxyl value is 40 mgKOH / g; the number average molecular weight of EVOH is 3000, and the molar percentage of vinyl alcohol units is 40 mol%.

[0074] The preparation method of above-mentioned barrier thermoplastic polyurethane elastomer comprises the steps:

[0075] (1) carry out drying treatment to diisocyanate, polyether polyol and chain extender;

[0076] (2) Add the dry formula amount of diisocyanate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com