Method for one-step synthesis of aniline-aniline derivative copolymer-coated magnetic nanoparticles

A technology of magnetic nanoparticles and aniline derivatives, applied in the field of magnetic nanoparticles, can solve the problems of limiting electrical and magnetic properties of conductive polymers, achieve low raw material costs, improve electrical and magnetic properties, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

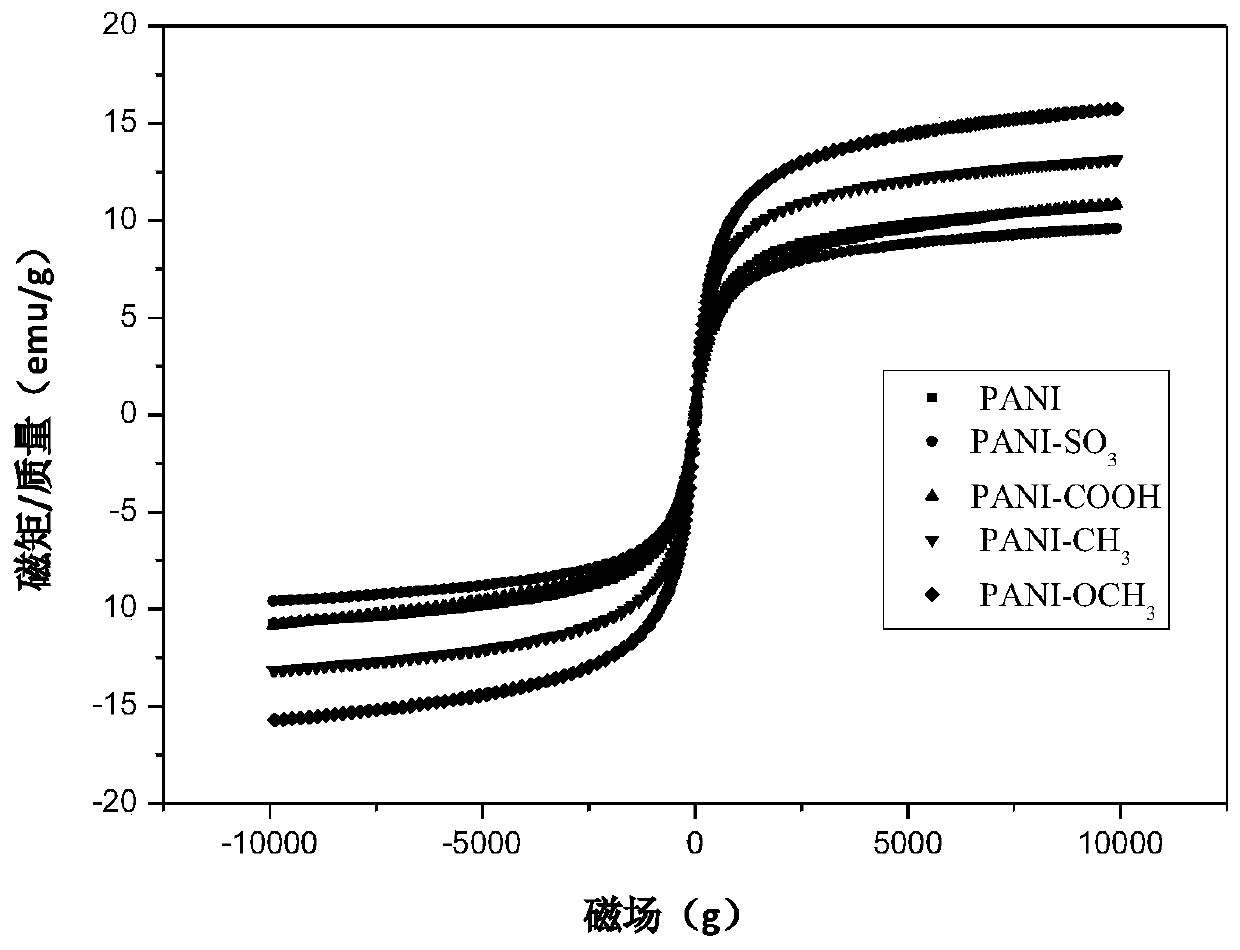

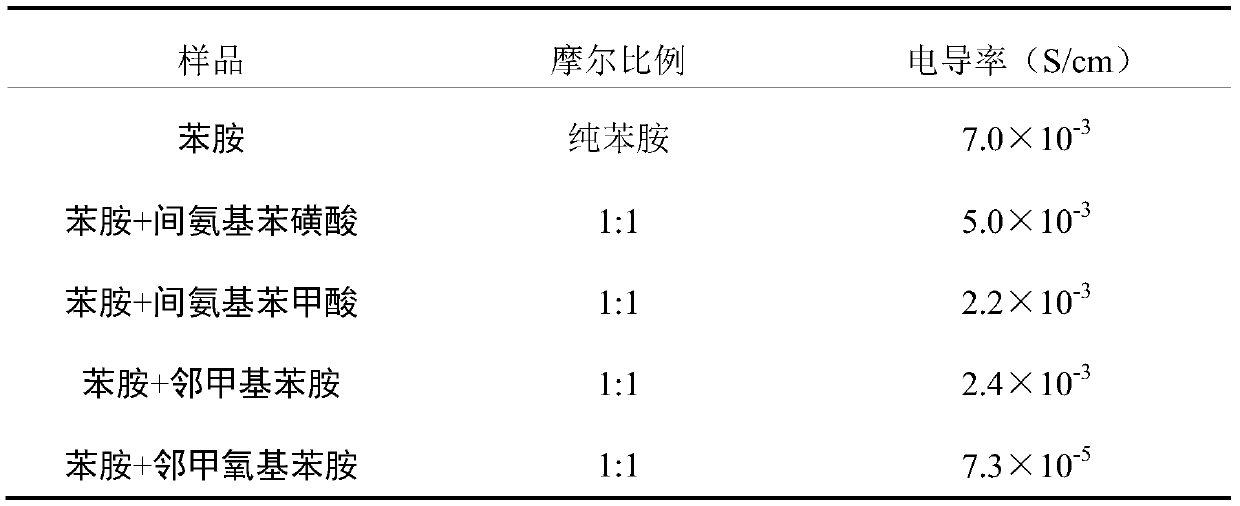

[0033] This example relates to a one-step method for synthesizing magnetic nanoparticles coated with aniline-aniline derivative copolymer. Specifically, aniline and m-aminobenzenesulfonic acid were added into a certain amount of 10 mL of 1M ammonia water at a molar ratio of 1:1, and ultrasonically dispersed to form a white emulsion. Then the white emulsion was stirred in a water bath at 37°C at 300 rpm, and after constant temperature, 1.8 mmol of ferrous chloride aqueous solution was added thereto, and then 45 mmol of ferric chloride solution was added dropwise. The system was allowed to react with stirring for 12 h to obtain a black solid. The resulting black solid was filtered, washed with distilled water until neutral, washed with ethanol until colorless, and finally washed three times with ether and dried in vacuum to obtain Fe coated with aniline-m-aminobenzenesulfonic acid copolymer. 3 o 4 magnetic nanoparticles.

Embodiment 2

[0035] This example relates to a one-step method for synthesizing magnetic nanoparticles coated with aniline-aniline derivative copolymer. Specifically, aniline and m-aminobenzoic acid were added to a certain amount of 10 mL of 1M ammonia water at a molar ratio of 1:1, and ultrasonically dispersed to form a white emulsion. Then the white emulsion was stirred in a water bath at 37°C at 300 rpm, and after constant temperature, 1.8 mmol of ferrous chloride aqueous solution was added thereto, and then 45 mmol of ferric chloride solution was added dropwise. The system was allowed to react with stirring for 12 h to obtain a black solid. The resulting black solid was filtered, washed with distilled water until neutral, then washed with ethanol until colorless, and finally washed three times with ether and dried in vacuum to obtain Fe coated with aniline-m-aminobenzoic acid copolymer. 3 o 4 magnetic nanoparticles.

Embodiment 3

[0037] This example relates to a one-step method for synthesizing magnetic nanoparticles coated with aniline-aniline derivative copolymer. Specifically, aniline and o-methylaniline were added into a certain amount of 10 mL of 1M ammonia water at a molar ratio of 1:1, and ultrasonically dispersed to form a white emulsion. Then the white emulsion was stirred in a water bath at 37°C at 300 rpm, and after constant temperature, 1.8 mmol of ferrous chloride aqueous solution was added thereto, and then 45 mmol of ferric chloride solution was added dropwise. The system was allowed to react with stirring for 12 h to obtain a black solid. The resulting black solid was filtered, washed with distilled water until neutral, then washed with ethanol until colorless, and finally washed three times with ether and dried in vacuum to obtain Fe coated with aniline-o-methylaniline copolymer. 3 o 4 magnetic nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com