A kind of graphene coating and preparation method for anticorrosion in sea mud area

A graphene and coating technology, applied in anti-corrosion coatings, fire-resistant coatings, epoxy resin coatings, etc., can solve problems such as difficulty in dispersion, easy re-aggregation of graphene, and achieve enhanced anti-corrosion performance, better adsorption effect, and excellent composition. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

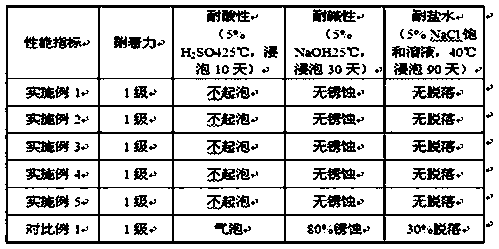

Examples

Embodiment 1

[0034] (1) Disperse 10 parts by weight of hollow mesoporous silica microspheres with a particle size of 10 μm and a pore size of 10 nm, 20 parts by weight of graphene and 2 parts by weight of silver powder with a particle size of 60 nm in 30 parts by weight of a dispersion medium at 30°C In ethanol, shake and stir, so that the surface of hollow mesoporous silica microspheres is evenly loaded with graphene and silver powder;

[0035] (2) Add 16 parts by weight of propylene glycol resin monomer and dimethyl silicone oil monomer mixture to (1) and stir at a high speed, the stirring speed is 500rpm, and stir for 20 minutes, so that the resin monomer wraps the medium loaded with graphene and silver powder. porous silica microspheres to obtain a composite microsphere suspension;

[0036] (3) Add 1 part by weight of cumene hydroperoxide whose temperature is controlled at 80°C to the composite microsphere suspension described in (2) in the form of dropwise addition at a rate of 10 dro...

Embodiment 2

[0039] (1) 20 parts by weight of hollow mesoporous silica microspheres with a particle size of 1 μm and a pore size of 40 nm, 15 parts by weight of a mixture of double-layer graphene, graphene oxide and nitrogen-doped graphene, and 5 parts by weight Silver powder with a particle size of 300nm is dispersed in 20 parts by weight of deionized water as a dispersion medium at 60°C, oscillating and stirring, so that the surface of hollow mesoporous silica microspheres is evenly loaded with graphene and silver powder;

[0040](2) Add 40 parts by weight of propylene glycol resin monomer and simethicone monomer mixture to (1) and stir at a high speed at a stirring speed of 200rpm, and stir for 50 minutes to make the resin monomer wrap the graphene-loaded and silver powder. Mesoporous silica microspheres to obtain a composite microsphere suspension;

[0041] (3) 2 parts by weight of the mixture of azobisisobutyronitrile, benzoyl, dicumyl peroxide and di-tert-butyl peroxide, which is con...

Embodiment 3

[0044] (1) 12 parts by weight of hollow mesoporous silica microspheres with a particle size of 3 μm and a pore size of 25 nm, 15 parts by weight of a mixture of double-layer graphene, multilayer graphene, and graphene oxide, and 7 parts by weight of particles Silver powder with a diameter of 120nm is dispersed in 28 parts by weight of xylene as a dispersion medium at 35°C, oscillating and stirring, so that the surface of the hollow mesoporous silica microspheres is uniformly loaded with graphene and silver powder;

[0045] (2) Add 35 parts by weight of phenolic resin monomer, propylene glycol resin monomer and dimethyl silicone oil monomer to (1) and stir at a high speed at a stirring speed of 480rpm, and stir for 25 minutes to make the resin monomer wrap the loaded graphene Mesoporous silica microspheres with silver powder to obtain a composite microsphere suspension;

[0046] (3) Add 1.5 parts by weight of a mixture of tert-butyl hydroperoxide, benzoyl and di-tert-butyl pero...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com