Waterborne anticorrosive coating and preparation method thereof

A water-based technology for anti-corrosion coatings, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of only weather resistance, single function of water-based resin, and only film-forming function, etc., to achieve mature reaction methods, Significant technical progress, excellent water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

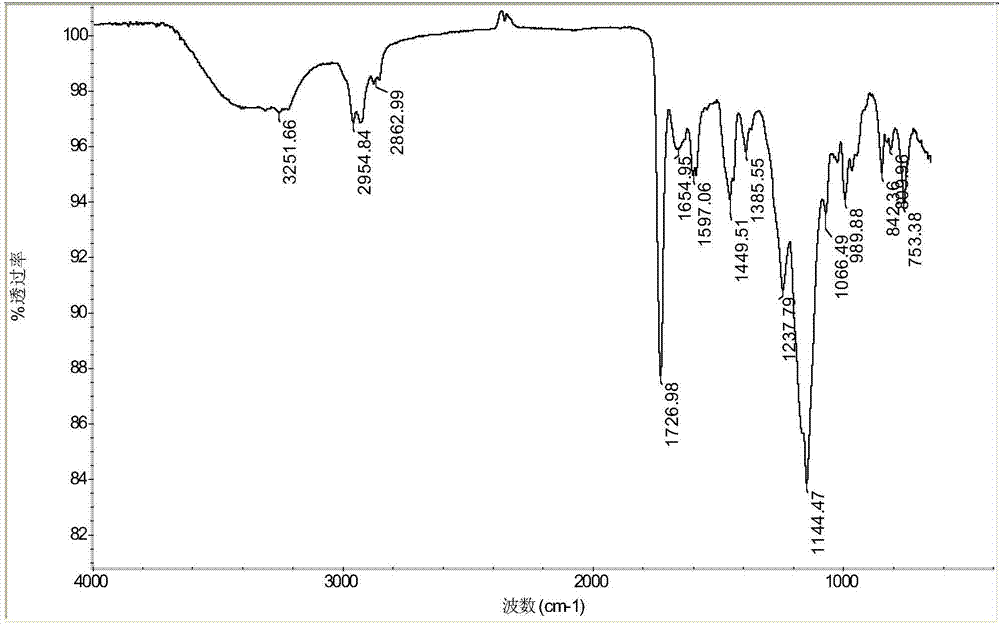

Image

Examples

Embodiment 1

[0078] A water-based anticorrosive coating, calculated in parts by weight, and its raw material composition and content are as follows:

[0079] 5 parts of hydrophilic modified aliphatic polyisocyanate curing agent;

[0080] 60 parts of water-based resin;

[0081] Leveling agent 0.05 parts;

[0082] Wetting agent 1 part;

[0083] Thickener 1 part;

[0084] 0.2 parts of defoamer;

[0085] 2 parts of film forming aids;

[0086] 0.02 parts of catalyst;

[0087] 20 parts deionized water;

[0088] The hydrophilic modified aliphatic polyisocyanate curing agent is Bayhydur XP 2655 of Bayer, Germany;

[0089] The said leveling agent is BYK 346 of BYK company;

[0090] The wetting agent is NP-100 of Dow Company;

[0091] The thickener is RM 825 from Rohm and Haas Co., Ltd.;

[0092] The defoamer is Nopco NXZ from Henkel, Germany;

[0093] The said film-forming aid is dipropylene glycol butyl ether from Dow Chemical Company;

[0094] The catalyst is dibutyl tin dilaurate;

[0095] The above-mentioned prepara...

Embodiment 2

[0108] A water-based anticorrosive coating, calculated in parts by weight, and its raw material composition and content are as follows:

[0109] 8 parts of hydrophilic modified aliphatic polyisocyanate curing agent;

[0110] 70 parts of water-based resin;

[0111] 0.1 part of leveling agent;

[0112] 10 parts of wetting agent;

[0113] Thickener 3 parts;

[0114] 1 part of defoamer;

[0115] 1.0 part of catalyst;

[0116] 5 parts of film forming aids;

[0117] 40 parts deionized water;

[0118] The hydrophilic modified aliphatic polyisocyanate curing agent is Bayhydur XP 2655 of Bayer, Germany;

[0119] The said leveling agent is BYK 346 of BYK company;

[0120] The wetting agent is NP-100 of Dow Company;

[0121] The thickener is RM 825 from Rohm and Haas Co., Ltd.;

[0122] The defoamer is Nopco NXZ from Henkel, Germany;

[0123] The said film-forming aid is dipropylene glycol butyl ether from Dow Chemical Company;

[0124] The catalyst is stannous octoate;

[0125] The above-mentioned preparatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com