FeS2 nano-material with three-dimensional structure, and preparation method and application thereof

A nanomaterial and three-dimensional structure technology, applied in the field of materials, can solve the problems of inability to meet practical application requirements, low maximum specific capacity, complex preparation process, etc., and achieve the effects of low cost, simple preparation process and high electrochemical activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] More preferably, the ultrasonic spraying conditions adopted in the preparation method include: the ultrasonic spraying frequency is 1.5-2.5 MHz, the nozzle diameter is 0.3-1.4 mm, the angle between the nozzle and the horizontal plane is 60-120°, and the applied DC voltage is 7-30kV, the curing distance is 5-10cm, the temperature is 0-35°C, the relative humidity is 10%-70%, and the carrier gas flow rate is 10-1000sccm. More preferably, the preparation method includes: placing the Fe nanoparticles in an air atmosphere, raising the temperature to 200-600° C. at a heating rate of 1-10° C. / min, performing constant temperature heat treatment for 10 minutes to 50 minutes, and then cooling naturally to room temperature, forming Fe with a three-dimensional porous structure 2 o 3 nanochain.

[0028] More preferably, the preparation method comprises: the Fe 2 o 3 The nanochains are placed in a hydrogen sulfide atmosphere, and the temperature is raised to 100-400°C at a heating...

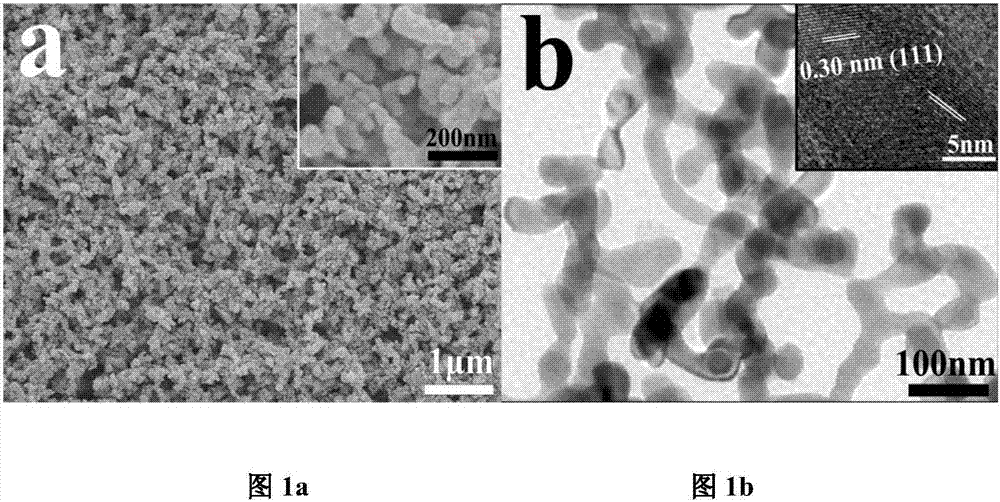

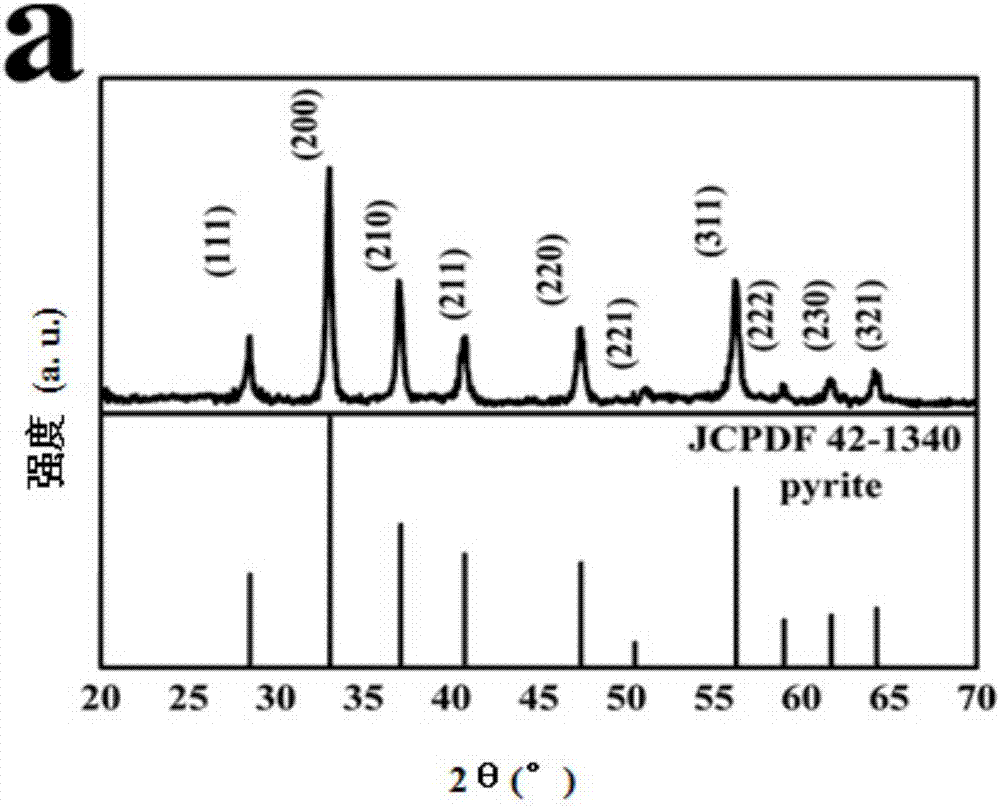

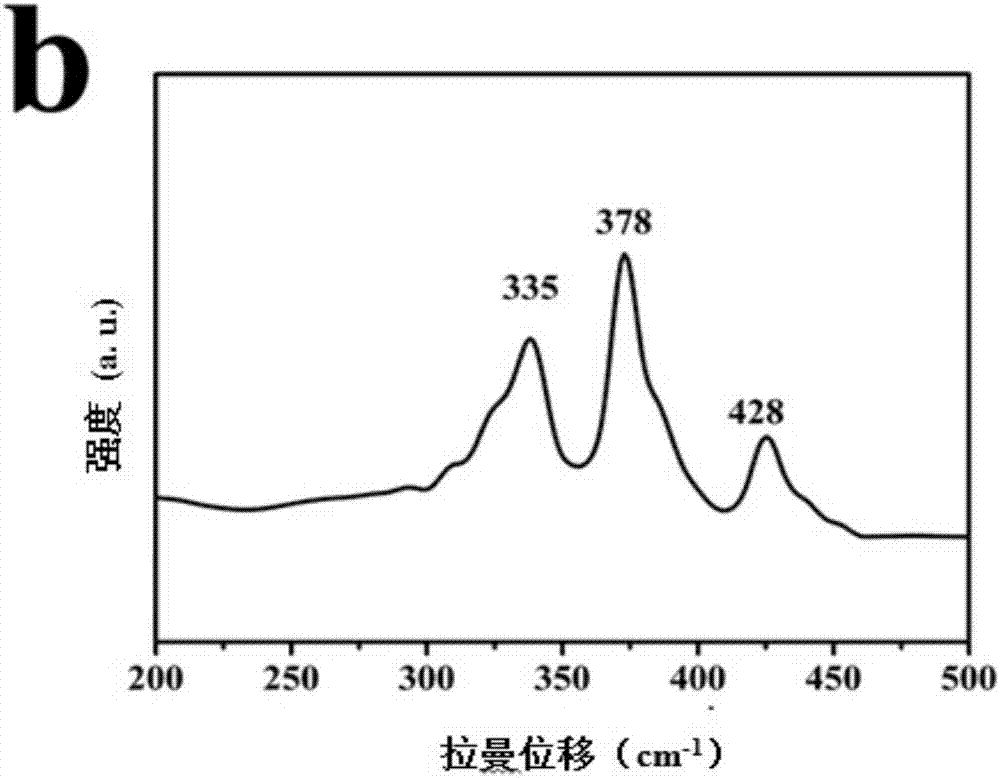

Embodiment 1

[0050] Embodiment 1: Fe(CO) 5 (0.06M) and acetone were mixed at a volume ratio of 1:35, and stirred under magnetic stirring (100 rpm) for 20 minutes to form a yellow transparent solution; then add the prepared precursor solution into two spray barrels of ultrasonic spray, Make an atomized spray. The ultrasonic spray frequency is 1.7MHz, the nozzle diameter is 0.4mm, the angle between the nozzle and the horizontal plane is adjusted to 90°, a DC voltage of 8kV is applied, the curing distance is 6cm, the temperature is 5°C, and the relative humidity is 5%. The Fe(CO ) 5 Small droplets with a diameter of about 5 μm were brought out by compressed air (gas flow rate 30 sccm), and the droplets were sprayed onto a hot plate with a surface temperature of 60 °C to generate a large amount of carbon monoxide gas and Fe nanoparticles. The above-mentioned Fe nanoparticles prepared by ultrasonic spraying were put into a tube furnace for heat treatment in an air atmosphere (gas flow rate 50...

Embodiment 2

[0051] Embodiment 2: Fe(CO) 5 (0.25M) and acetone are mixed at a volume ratio of 1:35, and stirred for 50 minutes under magnetic stirring (1800 rpm) to form a yellow transparent solution; then add the prepared precursor solution into the two spray barrels of ultrasonic spray, Make an atomized spray. The ultrasonic spray frequency is 1.7MHz, the nozzle diameter is 1.2mm, the angle between the nozzle and the horizontal plane is adjusted to 90°, a DC voltage of 25kV is applied, the curing distance is 8cm, the temperature is 30°C, and the relative humidity is 60%. Fe(CO ) 5 Small droplets with a diameter of about 5 μm were brought out by compressed air (gas flow rate 800 sccm), and the droplets were sprayed onto a hot plate with a surface temperature of 160 °C to generate a large amount of carbon monoxide gas and Fe nanoparticles. The above-mentioned Fe nanoparticles prepared by ultrasonic spraying were put into a tube furnace for heat treatment in an air atmosphere (gas flow ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com