Preparation of amorphous calcium phosphate/polylactic acid electrostatic spinning bracket

An amorphous calcium phosphate and electrospinning technology, applied in medical science, prosthesis, etc., can solve the problems of limited donor sources, secondary injury of patients, and limited capacity, and achieve real-time monitoring of the operation process and good biocompatibility Sexuality and degradability, the effect of promoting osseointegration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Preparation of amorphous calcium phosphate precursor by chemical wet method

[0022] In the experiment, the amorphous calcium phosphate precursor was prepared by chemical wet method, and 2.95g Ca(NO 3 ) 2 4H 2 O and 0.99g (NH 4 ) 2 HPO 4 Ensure that Ca / P=1.67, dissolve with 20mL of distilled water respectively, and obtain 12.5mmol of Ca(NO 3 ) 2 4H 2 O and 7.5mmol of (NH 4 ) 2 HPO 4 solution. Slowly drop the solution containing calcium ions into the solution containing phosphate, stir slowly with a glass rod to mix the solution evenly, and adjust the pH of the solution with ammonia water to keep the pH value of the reaction system at about 7.4. The obtained mixture was poured into a 50mL centrifuge tube, centrifuged at 3000rpm for 3min, and freeze-dried to obtain amorphous calcium phosphate powder, which was ready for use.

Embodiment 2

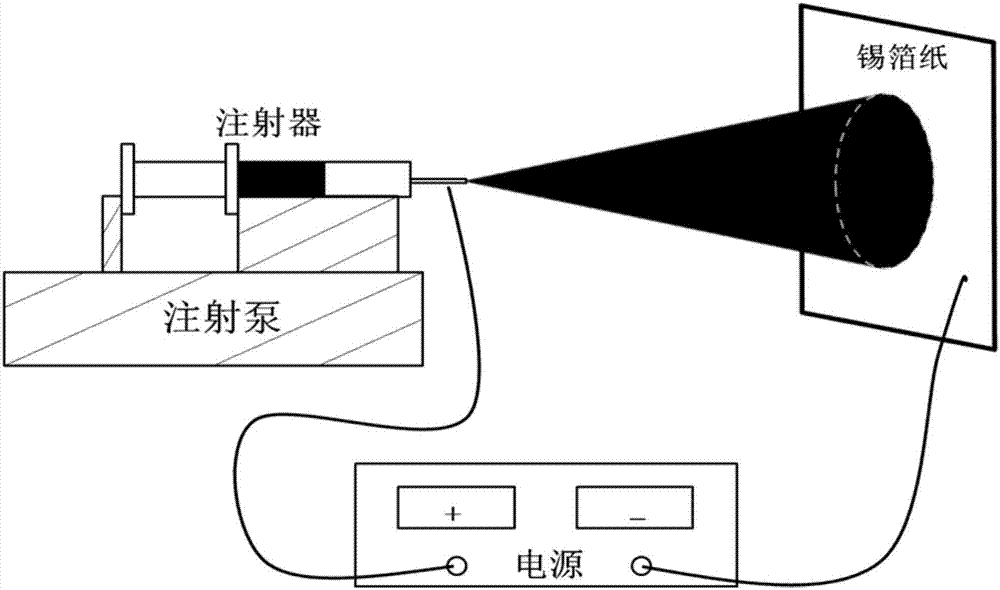

[0023] Example 2: Preparation of polylactic acid electrospinning scaffold

[0024] Pipette 7mL of dichloromethane and 3mL of N,N-dimethylformamide into a small beaker to make a mixed solvent, weigh 9g of polylactic acid with a balance and dissolve it in the mixed solvent to obtain 9% (W / V) PLA electrospinning solution. The prepared spinning solution was transferred into a 20mL syringe for electrospinning. In the experiment, the electrospinning voltage was set to 20kV, the receiving distance was 12cm, and the advancing rate of the syringe pump was 0.4mL / h. Electrospun films of lactic acid.

Embodiment 3

[0025] Example 3: Preparation of polylactic acid electrospinning scaffold

[0026] Use a pipette gun to pipette 7mL of dichloromethane and 3mL of N,N-dimethylformamide into a small beaker to make a mixed solvent, weigh 11g of polylactic acid with a balance and dissolve it in the mixed solvent to obtain 11% (W / V) PLA electrospinning solution. The prepared spinning solution was transferred into a 20mL syringe for electrospinning. In the experiment, the electrospinning voltage was set to 20kV, the receiving distance was 12cm, and the advancing rate of the syringe pump was 0.4mL / h. Electrospun films of lactic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com