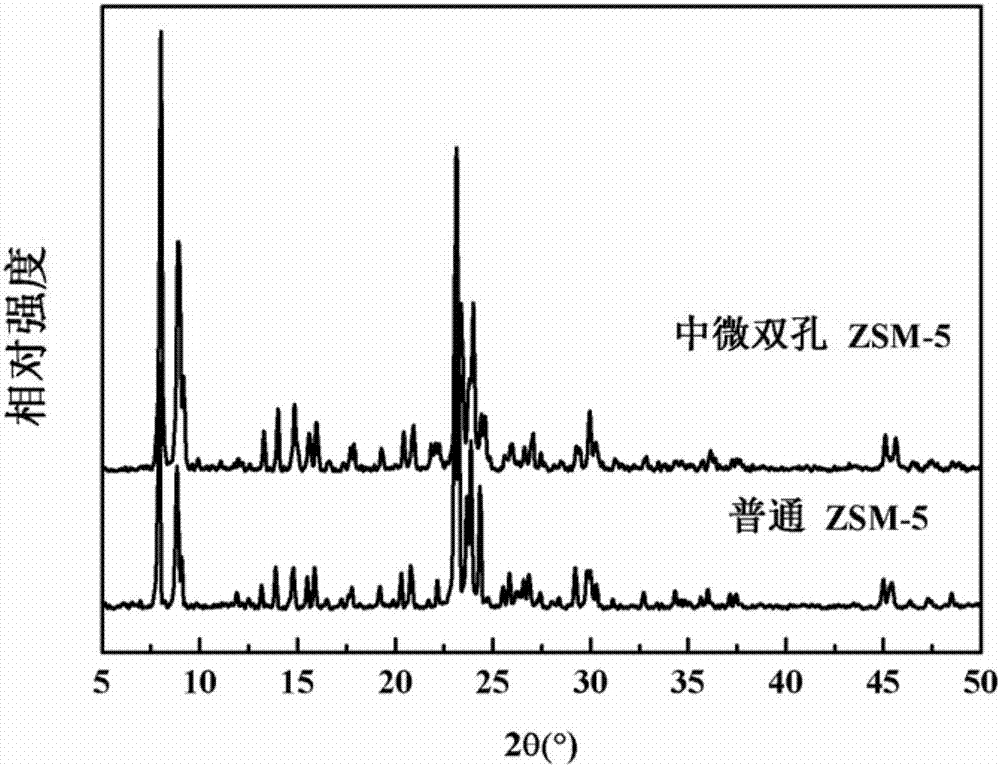

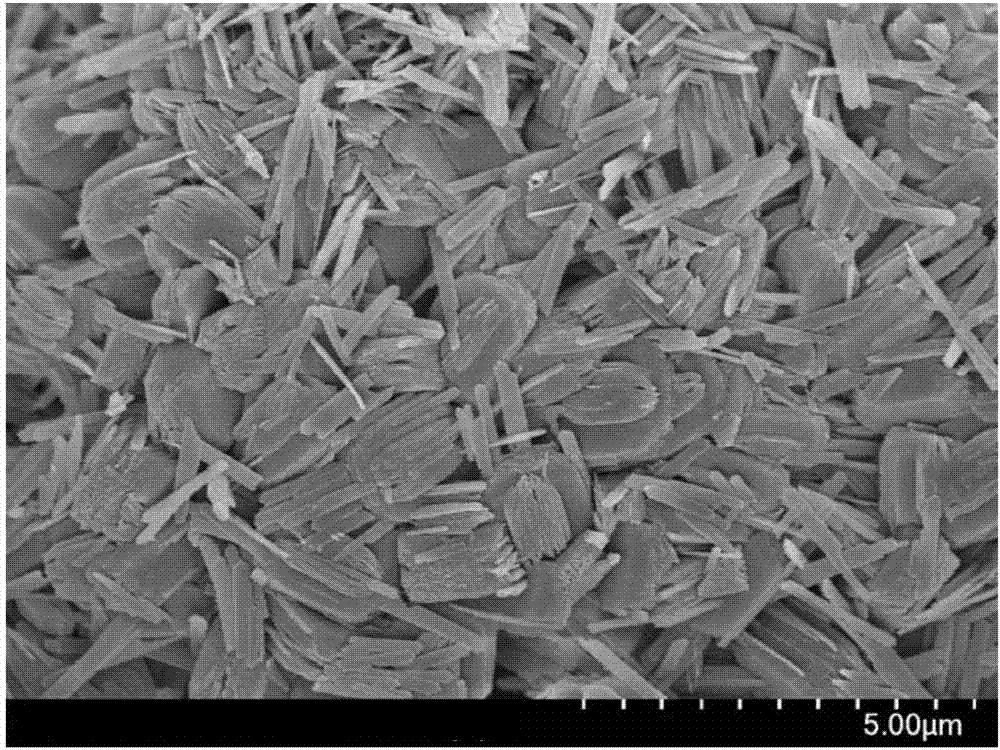

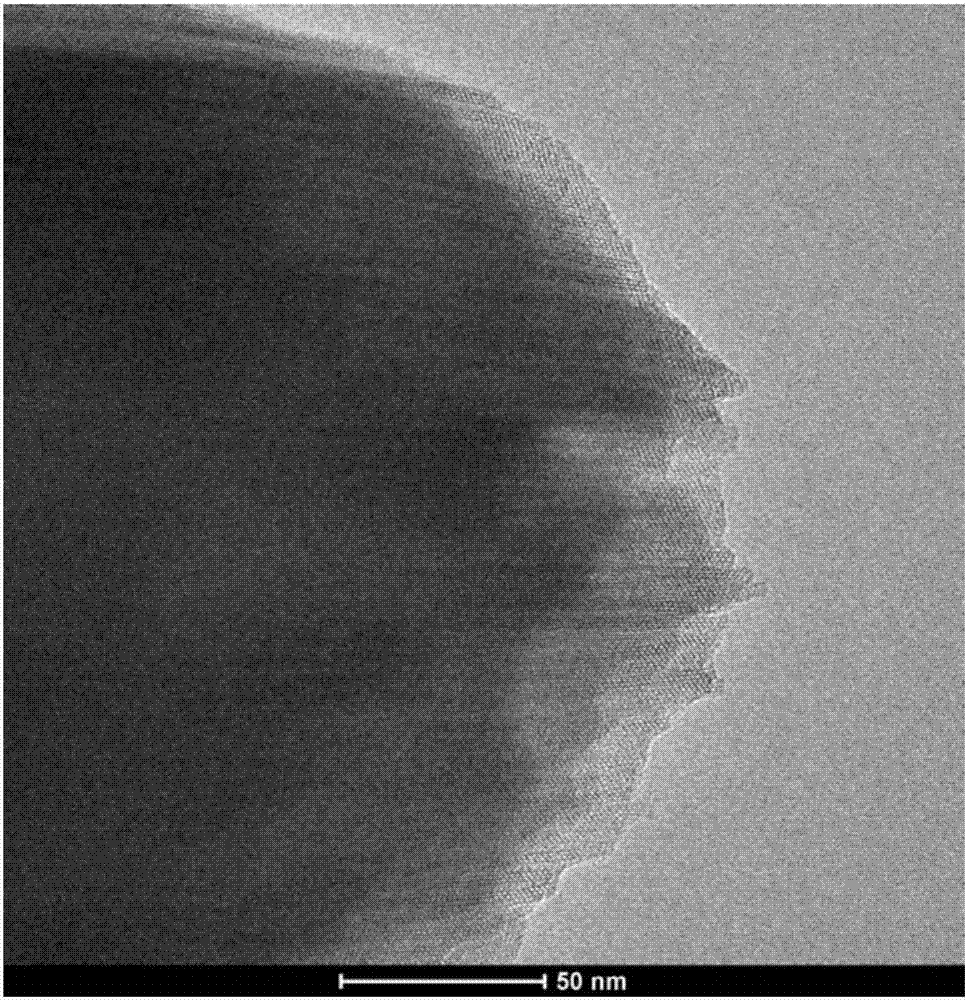

Preparation method of micro-mesoporous ZSM-5 zeolite molecular sieve

A zeolite molecular sieve, medium-micro double-porous technology, applied in the directions of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of complex preparation process and long synthesis period, and achieve simple process, Low cost and the effect of improving mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Mix 1g of single-head quaternary ammonium salt surfactant and 18ml of deionized water to obtain liquid A, add 0.081g of sodium metaaluminate (44.7 wt% Na 2 O, 52 wt% Al 2 O 3 , J&K), 0.37g sodium hydroxide and 14ml deionized water are mixed uniformly to obtain B solution, 8.654g ethyl orthosilicate (98 wt%, J&K) and 0.404g tetrapropylammonium hydroxide (40wt% aqueous solution, ρ = 1.012g / ml) Mix well to obtain liquid C;

[0040] (2) Add liquid A to liquid B to obtain liquid D under stirring conditions of 55°C and 300 rpm, and continue stirring for 1 hour;

[0041] (3) Continue to add liquid C dropwise to liquid D under stirring conditions of 55°C and 300 rpm to obtain a gel, and continue stirring for 7 hours;

[0042] (4) Put the product of step (3) in an autoclave, hydrothermally crystallize at 140°C for 110 hours, filter and wash with deionized water after the crystallization reaction is completed, and dry at 120°C for 10 hours;

[0043] (5) Place the product of step (4) ...

Embodiment 2

[0045] (1) Mix 1g single-head quaternary ammonium salt surfactant and 18ml deionized water to obtain liquid A, add 0.078g sodium metaaluminate (44.7 wt% Na 2 O, 52 wt% Al 2 O 3 , J&K), 0.36g sodium hydroxide and 13ml deionized water mixed uniformly to obtain B solution. Combine 8.333g ethyl orthosilicate (98 wt%, J&K) and 0.404g tetrapropylammonium hydroxide (40 wt% aqueous solution, ρ = 1.012g / ml) Mix well to get C solution;

[0046] (2) Add liquid A to liquid B to obtain liquid D under stirring conditions of 60°C and 300 rpm, and continue stirring for 2 hours;

[0047] (3) Continue to add liquid C dropwise to liquid D under stirring conditions of 60°C and 300 rpm to obtain a gel, and continue stirring for 8 hours;

[0048] (4) Put the product of step (3) in an autoclave, hydrothermally crystallize at 150°C for 120h, filter and wash with deionized water after the crystallization reaction is completed, and dry at 120°C for 10h;

[0049] (5) Place the product of step (4) in a muffle fu...

Embodiment 3

[0051] (1) Mix 1g of single-head quaternary ammonium salt surfactant and 18ml of deionized water to obtain liquid A, add 0.076g of sodium metaaluminate (44.7 wt% Na 2 O, 52 wt% Al 2 O 3 , J&K), 0.33g sodium hydroxide and 10ml deionized water are mixed uniformly to obtain liquid B. Combine 8.119g ethyl orthosilicate (98 wt%, J&K) and 0.404g tetrapropylammonium hydroxide (40 wt% aqueous solution, ρ = 1.012g / ml) Mix well to get C solution;

[0052] (2) Add liquid A to liquid B to obtain liquid D under stirring conditions of 65°C and 300 rpm, and continue stirring for 3 hours;

[0053] (3) Continue to add liquid C dropwise to liquid D under stirring conditions of 65°C and 300 rpm to obtain a gel, and continue stirring for 9 hours;

[0054] (4) Put the product of step (3) in an autoclave, hydrothermally crystallize it at 150°C for 130h, filter and wash with deionized water after the crystallization reaction, and dry it at 120°C for 10h;

[0055] (5) Place the product of step (4) in a muffl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com