Method for preparing capacitor electrode material non-stoichiometric lanthanum manganate

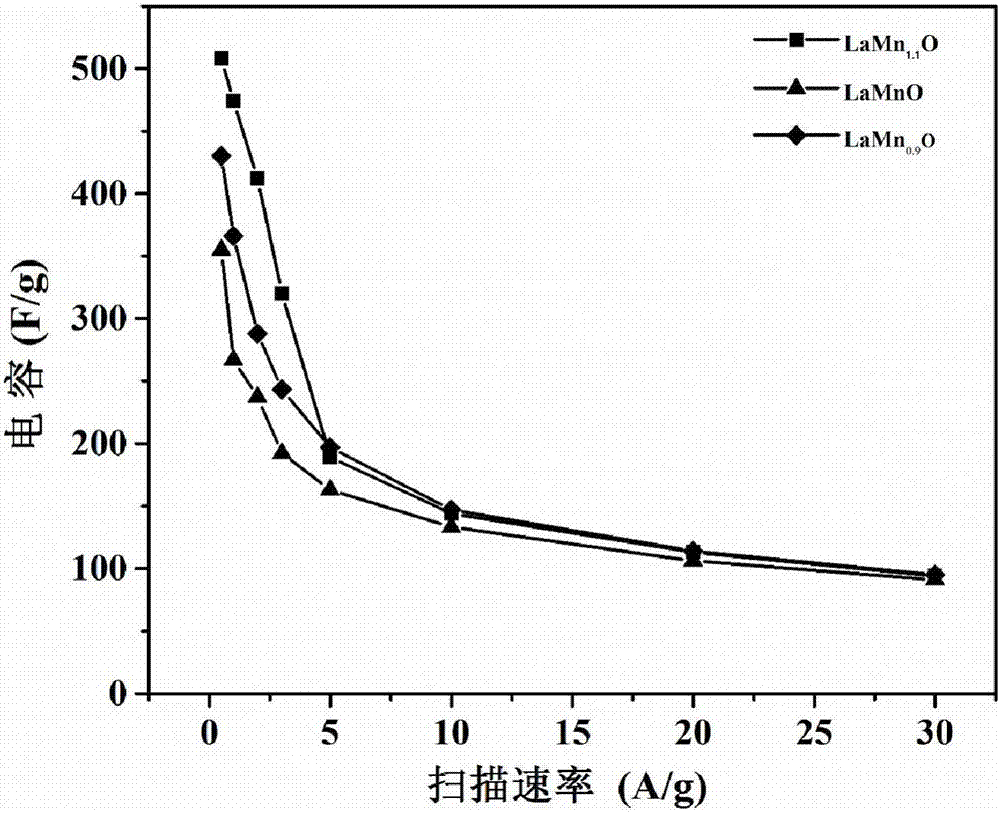

A technology for stoichiometric lanthanum manganate and electrode materials, applied in hybrid capacitor electrodes, nanotechnology for materials and surface science, manganate/permanganate, etc. Time and other issues, to achieve the effect of low cost, good material performance, high cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

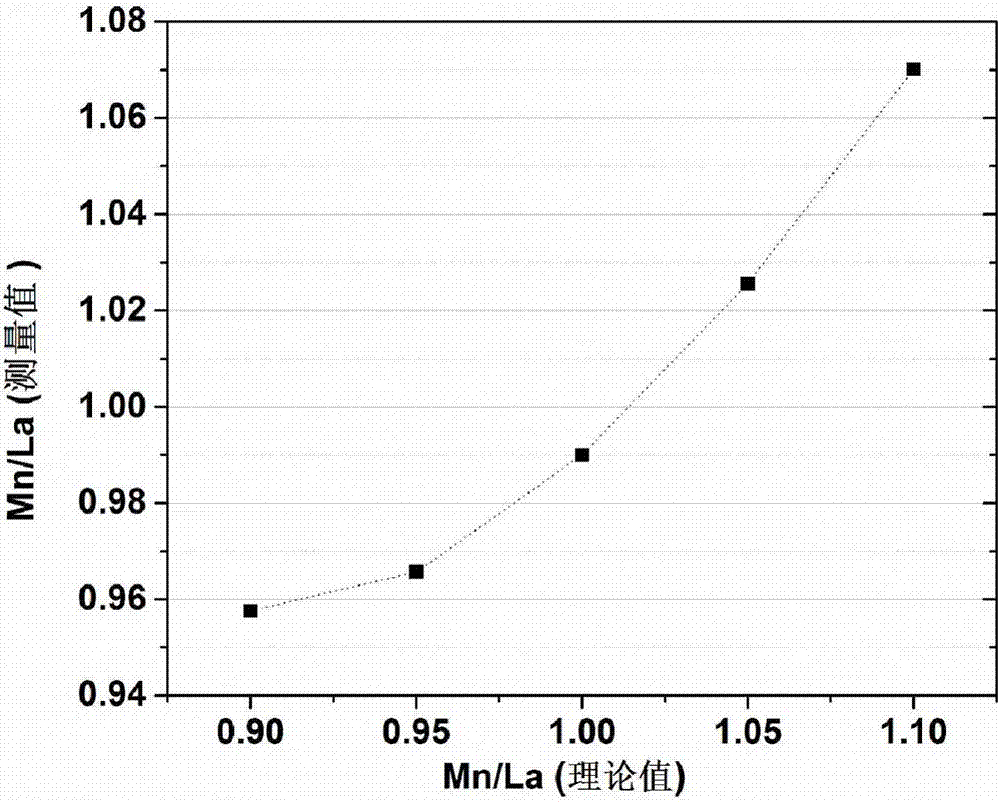

[0026] (1) Weigh 26.846g of lanthanum nitrate hexahydrate and add it to 20mL of water under the action of magnetic stirring. Then, 12.2044 g of manganese nitrate (Mn / La molar ratio=1.1) was weighed and added to the above solution, and stirred for 2 h to ensure that a homogeneously mixed nitrate mixture was obtained. Then 10.4 mL of citric acid (15.5 mol / L) was added dropwise.

[0027] (2) The above mixed solution was placed in a water bath at 80°C, vigorously stirred for 4 hours, and the excess water was evaporated until a brown gel was obtained. The obtained sol-gel was transferred to a vacuum drying oven and dried at 140 °C for 8 h.

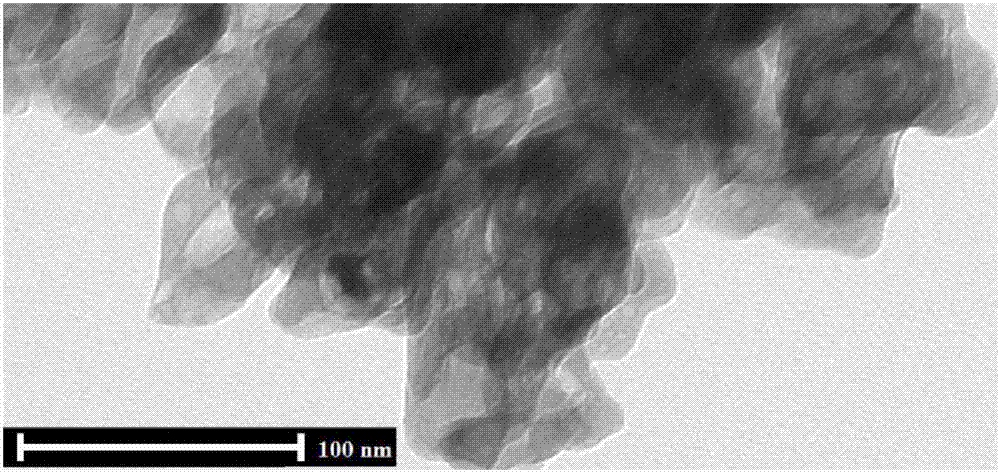

[0028] (3) The xerogel obtained in the above steps was put into an agate mortar and ground, then transferred to a tube furnace, and preheated to 350° C. for 10 minutes. The burnt powder was ground and calcined at 750°C for 4h in a tube furnace in an air atmosphere. Get LaMn 1.1 O 3 .

Embodiment 2

[0030] (1) Weigh 26.846g of lanthanum nitrate hexahydrate and add it to 20mL of water under the action of magnetic stirring. Then, 11.6496 g of manganese nitrate (Mn / La molar ratio=1.05) was weighed and added to the above solution, and stirred for 2 h to ensure that a uniformly mixed nitrate mixture was obtained. Then 10.2 mL of citric acid (15.5 mol / L) was added dropwise.

[0031] (2) The above mixed solution was placed in a water bath at 80°C, vigorously stirred for 4 hours, and the excess water was evaporated until a brown gel was obtained. The obtained sol-gel was transferred to a vacuum drying oven and dried at 140 °C for 8 h.

[0032] (3) The xerogel obtained in the above steps was put into an agate mortar and ground, then transferred to a tube furnace, and preheated to 350° C. for 10 minutes. The burnt powder was ground and calcined at 750°C for 4h in a tube furnace in an air atmosphere. Get LaMn 1.05 O 3 .

Embodiment 3

[0034] (1) Weigh 26.846g of lanthanum nitrate hexahydrate and add it to 20mL of water under the action of magnetic stirring. Then, 11.0949 g of manganese nitrate (Mn / La molar ratio=1.00) was weighed and added to the above solution, and stirred for 2 h to ensure that a homogeneously mixed nitrate mixture was obtained. Then 10.0 mL of citric acid (15.5 mol / L) was added dropwise.

[0035] (2) The above mixed solution was placed in a water bath at 80°C, vigorously stirred for 4 hours, and the excess water was evaporated until a brown gel was obtained. The obtained sol-gel was transferred to a vacuum drying oven and dried at 140 °C for 8 h.

[0036] (3) The xerogel obtained in the above steps was put into an agate mortar and ground, then transferred to a tube furnace, and preheated to 350° C. for 10 minutes. The burnt powder was ground and calcined at 750°C for 4h in a tube furnace in an air atmosphere. Get LaMnO 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com