Power plant flue gas waste heat direct evaporating desalination system with flue gas reheating function

A flue gas waste heat and reheating technology, applied in evaporation, lighting and heating equipment, heating water/sewage treatment, etc., can solve problems such as difficulty in flue gas waste heat recovery, heat exchange surface dew point corrosion, etc., to avoid back corona phenomenon , reduce equipment investment, reduce the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the drawings.

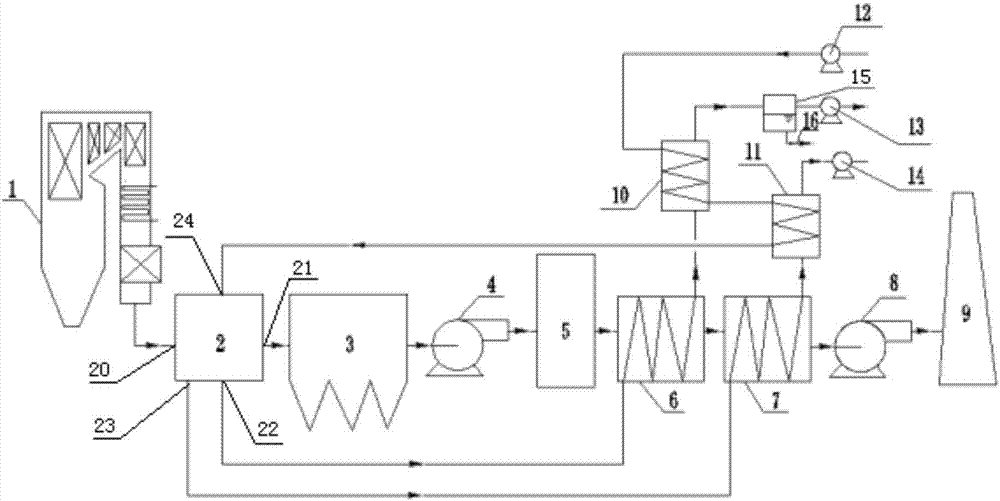

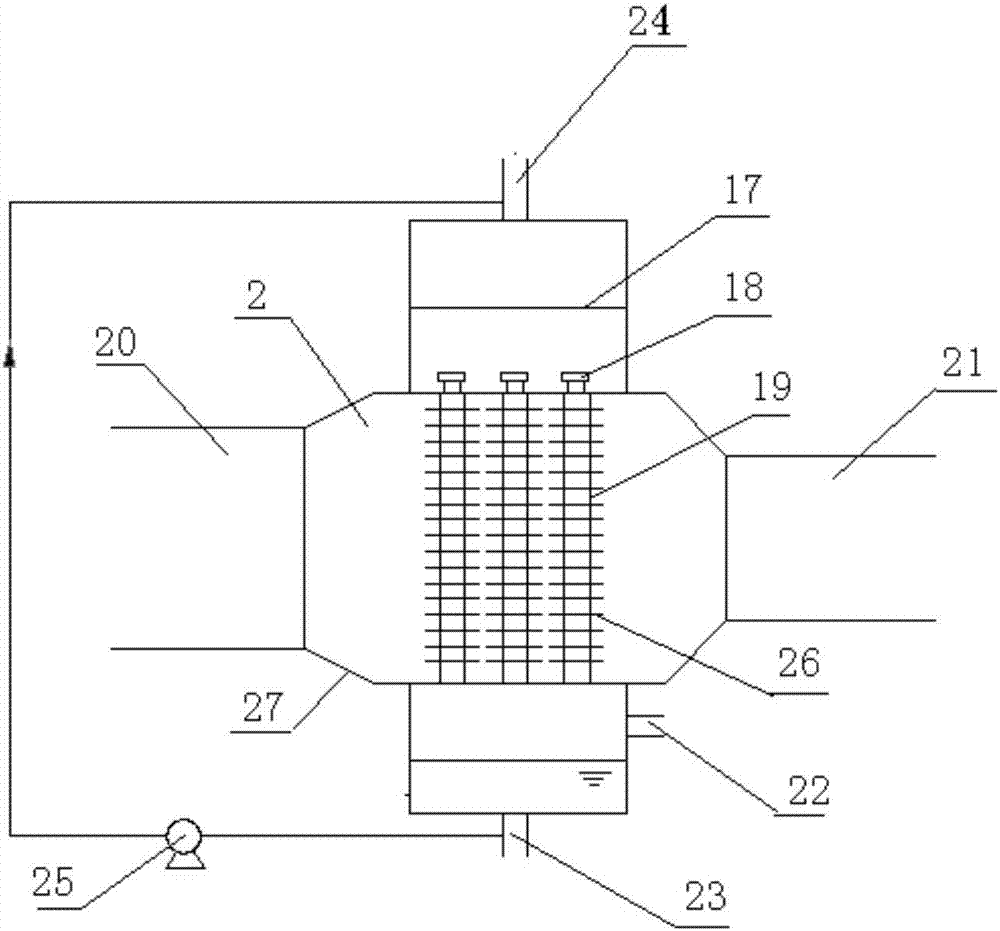

[0021] The power plant flue gas waste heat direct evaporation desalination system with flue gas reheating function, see figure 1 , Including the boiler 1, the boiler is connected to the hot flue gas inlet 20 of the flue gas waste heat seawater evaporator 2 through a pipeline, and the cold flue gas outlet 21 of the flue gas waste heat seawater evaporator 2 is connected to the electric precipitator 3, the induced draft fan 4 through the pipeline, The desulfurization tower 5, the shell side of the first flue gas heater 6, the shell side of the second flue gas heater 7, the booster fan 8 and the chimney 9 are connected; the steam outlet 22 of the flue gas waste heat seawater evaporator 2 is connected to The tube side of the first flue gas heater 6, the shell side of the first seawater preheater 10, the product water tank 15 and the vacuum pump 13 are connected; the concentrated water outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com