Metal-semiconductor-glass opto-electronic optical fiber and preparation method thereof

A technology of semiconductor and optical fiber, which is applied in the field of metal-semiconductor-glass photoelectric optical fiber and its preparation, can solve the problems of not being able to become photoelectric optical fiber and low conduction efficiency, achieve excellent performance and avoid the effect of interdiffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

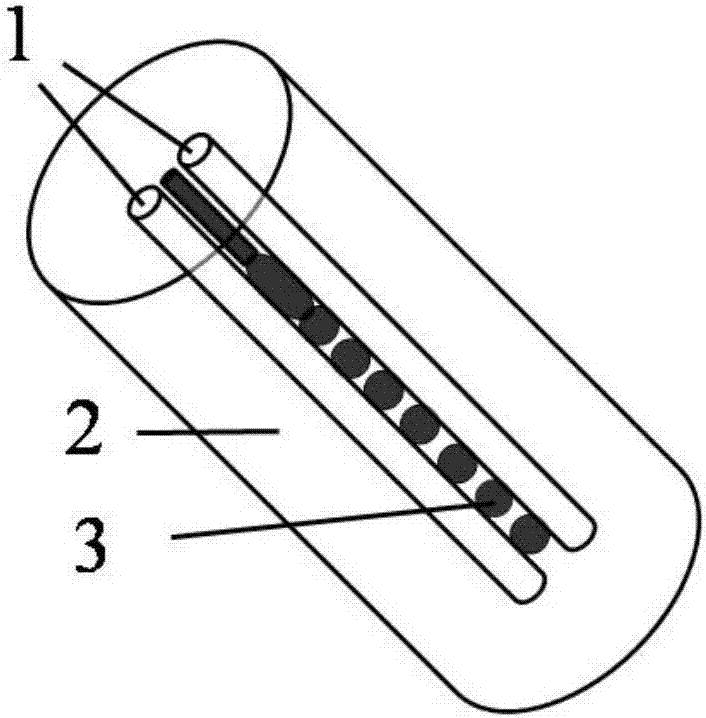

[0035] The preparation process of the metal aluminum-selenium tellurium semiconductor-phosphate glass photoelectric optical fiber of this embodiment is as follows:

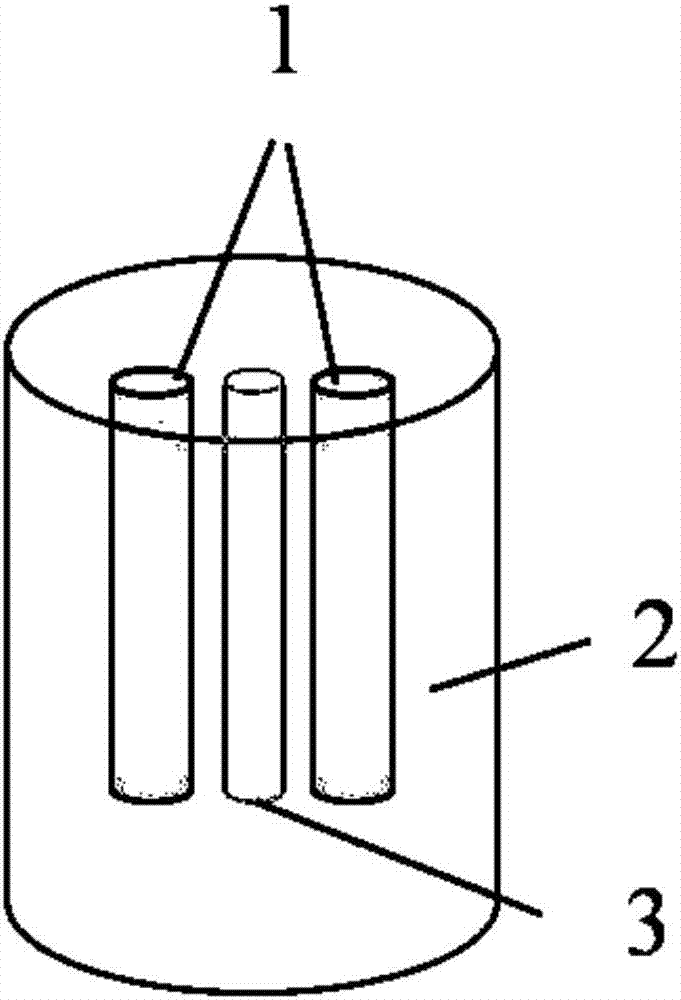

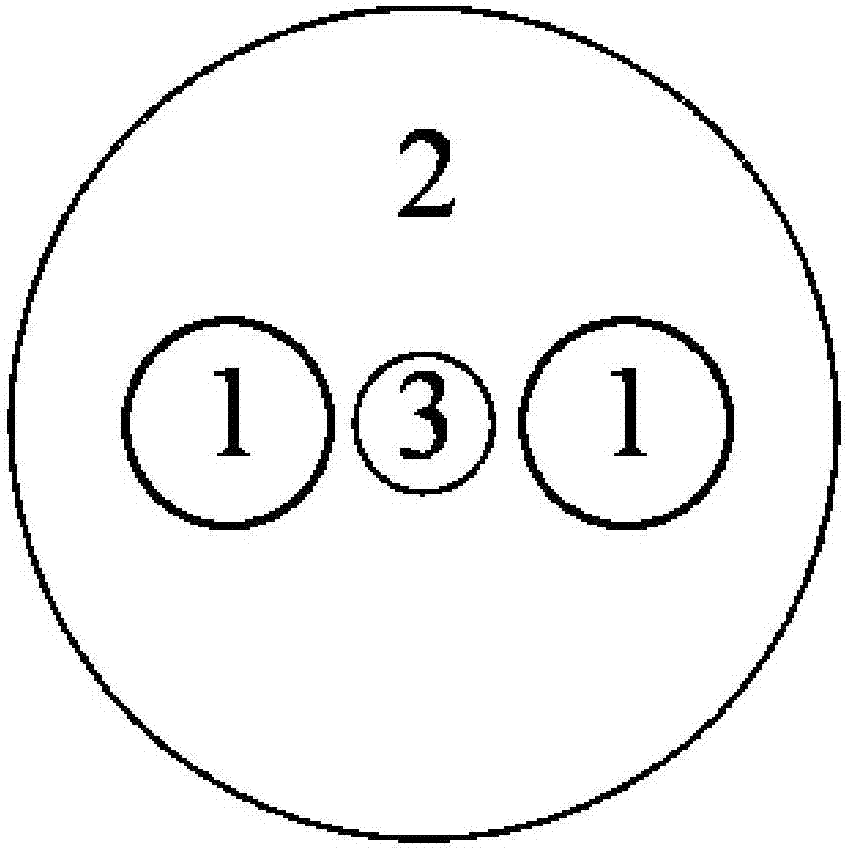

[0036] (1) Phosphate glass is mechanically cold processed into a clad glass rod with a diameter of 25mm and a length of 10cm, and then a central hole with a diameter of 3mm and a length of 8cm is drilled in the center of the clad glass rod along the axial direction; Drill two side holes with the same size as the center hole on both sides. All the holes are non-through holes, and the two side holes are symmetrically distributed with the center hole as the axis of symmetry. The center of the two side holes and the center hole The connecting line of the center is a straight line; finally, the inner wall of the hole and the outer surface of the glass rod are physically and chemically polished;

[0037](2) In the glove box, mix high-purity selenium and tellurium semiconductor powders according to the molar ratio in Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com