Method for preparing microcapsules through embedding xanthophyll with starch

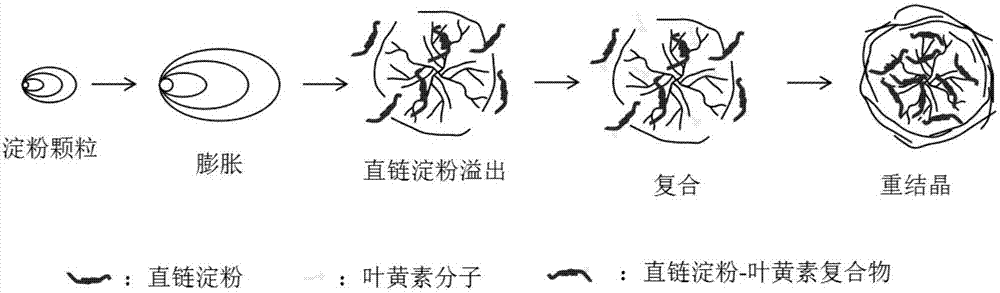

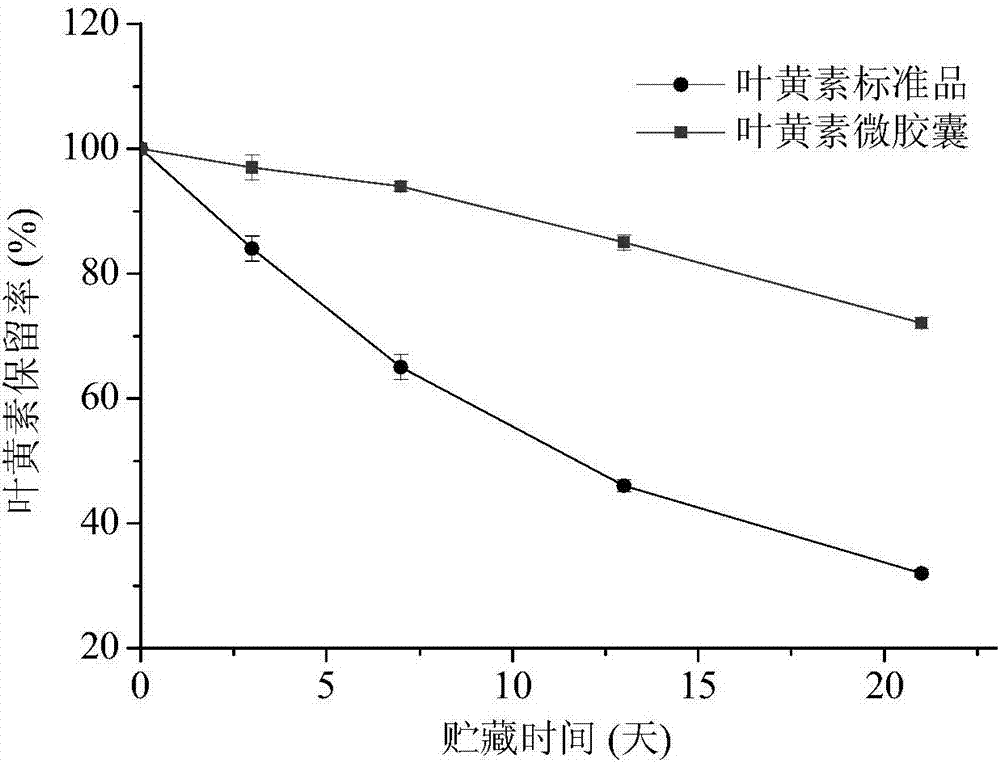

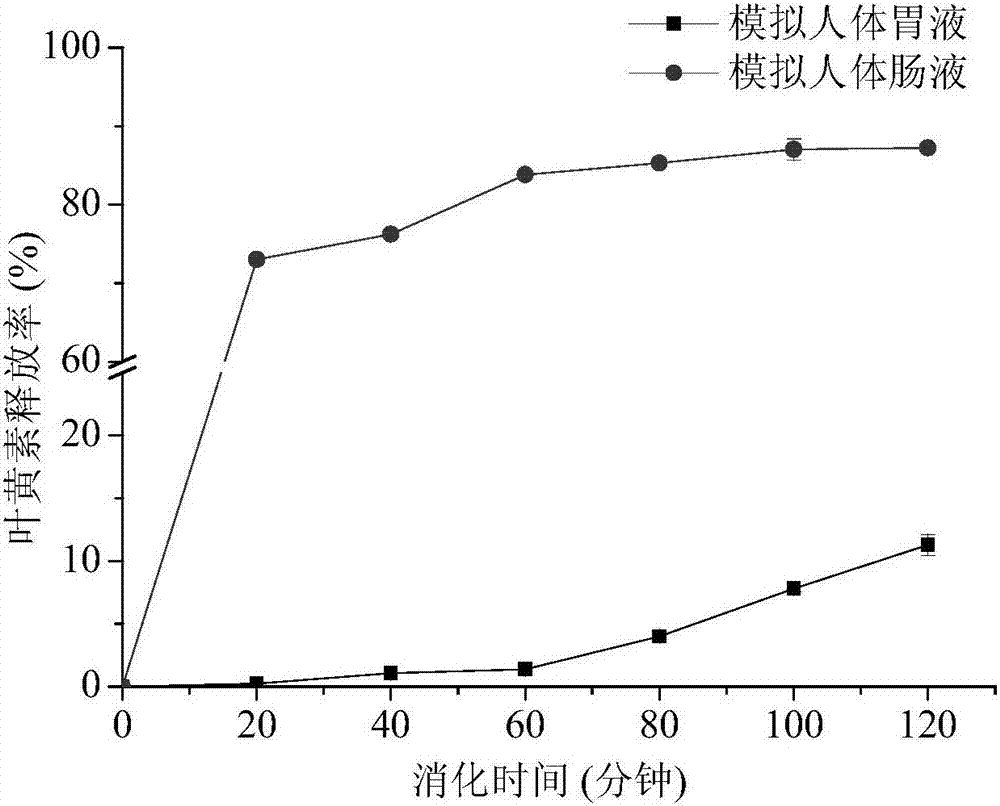

A lutein and microcapsule technology, applied in the food industry, can solve the problems of limited application, high energy consumption, unfavorable lutein protection, etc., and achieve favorable absorption and utilization, low energy consumption, stable intestinal targeting slow release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation of common corn starch lutein microcapsules comprises the following steps:

[0048] (1) Lutein dissolution: in mass fraction, 1 part of lutein standard product with a mass of 20 mg is dissolved in 5 parts of organic solvent, stirred at room temperature to make it evenly dispersed, and the organic solvent is ethanol;

[0049] (2) Expansion of ordinary cornstarch: in mass percentage, prepare 4% ordinary cornstarch slurry with distilled water, stir and mix, and heat it in a constant temperature water bath at 55°C for 1 hour, the starch granules expand and amylose overflows, forming expanded ordinary cornstarch ;

[0050] (3) mixing, embedding: in parts by mass, 1 part of lutein solution obtained in step (1) was added dropwise to 5 parts of the expanded common cornstarch slurry obtained in step (2) within 30min, and stirred Mixing, stirring at a speed of 300 rpm, and reacting in a constant temperature water bath at 55°C for 1 hour, so that the lutein can be ...

Embodiment 2

[0058] The preparation of potato starch lutein microcapsules comprises the following steps:

[0059] (1) Lutein dissolution: in terms of mass fraction, 1 part of lutein standard product with a mass of 20 mg is dissolved in 5 parts of organic solvents, and stirred at room temperature to make it uniformly dispersed; the organic solvent is ethanol;

[0060] (2) Potato starch expansion: in terms of mass fraction, prepare 6% potato starch slurry with distilled water, stir and mix, and react in a constant temperature water bath at 55°C for 1 hour to swell the starch and overflow the amylose to form expanded potato starch;

[0061] (3) mixing, embedding: 1 part of the lutein solution obtained in step (1) was added dropwise to 3 parts of the expanded potato starch slurry obtained in step (2) within 30min, stirred and mixed, and the stirring speed was 200rpm, And react in a constant temperature water bath at 65℃ for 1h, so that the lutein can be fully and evenly embedded by the amylose...

Embodiment 3

[0065] The preparation of common corn starch lutein microcapsules comprises the following steps:

[0066] (1) Lutein dissolution: in mass fraction, 1 part of the lutein standard product with a mass of 20 mg is dissolved in 5 parts of an organic solvent, stirred at room temperature to make it uniformly dispersed, and the organic solvent is ethanol;

[0067] (2) Expansion of ordinary corn starch: In terms of mass fraction, 6% ordinary corn starch slurry was prepared with distilled water, stirred and mixed, and reacted in a constant temperature water bath at 65°C for 1 hour to swell the starch granules and overflow the amylose to form expanded ordinary corn. starch;

[0068] (3) mixing, embedding: 1 part of the lutein solution obtained in step (1) was added dropwise to 5 parts of the expanded common cornstarch slurry obtained in step (2) in 30min, and the stirring speed was 300rpm. , and reacted in a constant temperature water bath at 65°C for 2 hours, so that the lutein can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com