Preparation method for tinidazole sodium chloride injection

A technology of nitrazole sodium chloride and injection, which is applied in the field of medicine, can solve problems such as poor stability, achieve the effects of reducing product content loss, avoiding the incidence of adverse reactions, and reducing operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

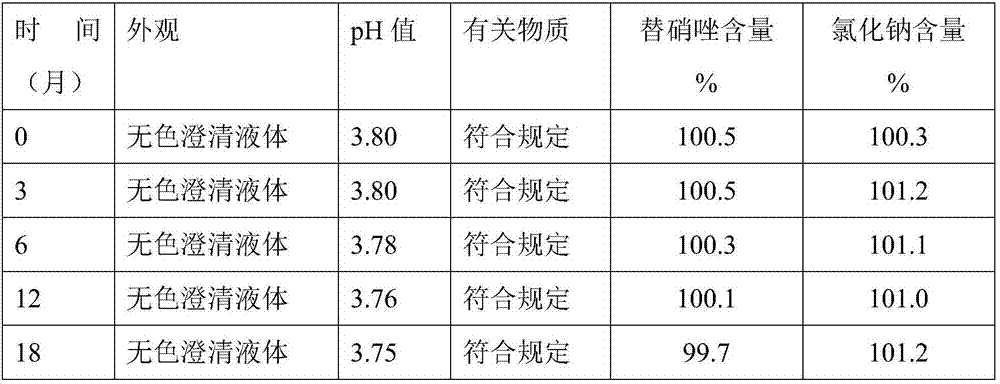

Image

Examples

specific Embodiment approach 1

[0022] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS A method for preparing tinidazole sodium chloride injection in the present invention, said injection is mainly made of tinidazole, sodium chloride, water for injection, specifically carried out according to the following steps :

[0023] Step 1, in the concentrated mixing tank, first add water for injection, under stirring, slowly add sodium chloride, make sodium chloride dissolve completely, be mixed with the solution of concentration 20% (mass), drop into gac [0.2% (W / V)] after the stirring process, then decarbonize and filter through a 20 micron titanium rod filter, then filter through a 0.45 micron polypropylene filter element, and the filtrate is poured into a dilute tank to obtain solution A;

[0024] Step 2. Rinse the concentrated preparation tank, add water for injection with 20% (mass) of the total amount of water for injection in the concentrated preparation tank, boil for 15 minutes, add tinidazole after cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com