Spray coating device for on-water floating solid-core polyurea elastomer

A technology of polyurea elastomer and spraying device, applied in liquid spraying device, spraying device and other directions, can solve the problems of low standardization, high labor intensity and low efficiency, and achieve low labor intensity, high production efficiency and broad market prospect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

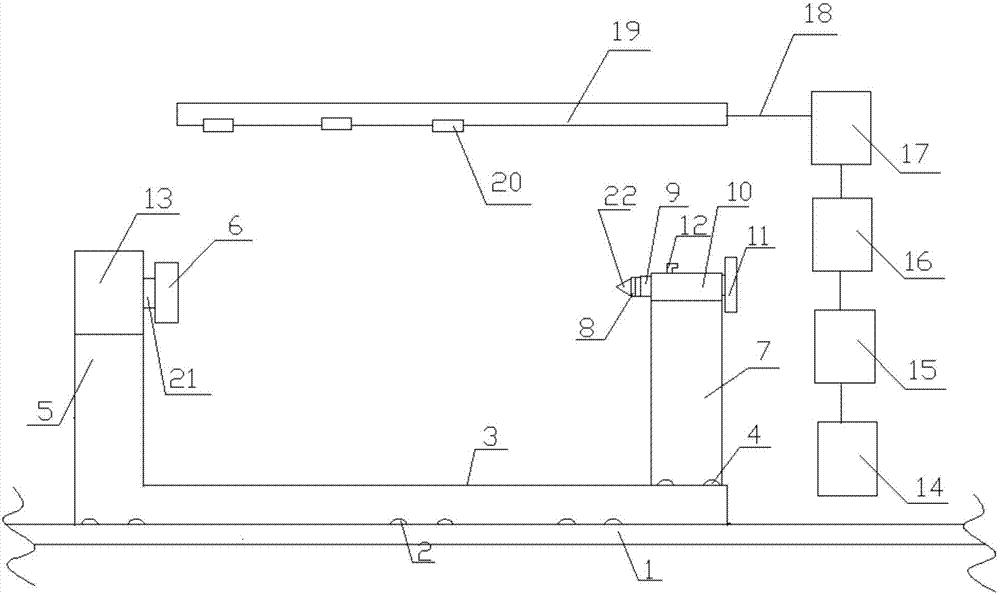

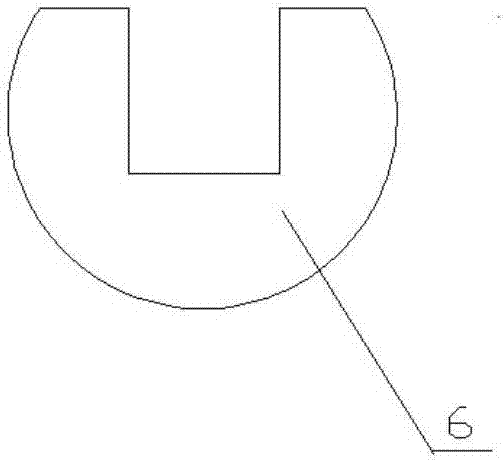

[0024]The main structure of the spraying device of the floating solid polyurea elastomer on water involved in this embodiment includes a first slide rail 1, a first pulley 2, a second slide rail 3, a second pulley 4, a first bracket 5, a first positioning Block 6, second bracket 7, second positioning block 8, first rotating shaft 9, sleeve 10, first rocker arm 11, positioning device 12, frequency conversion motor 13, air compressor 14, air storage tank 15, cold dryer 16. Double-tower drier 17, air pipe 18, sprayer 19, nozzle 20, second rotating shaft 21 and second connecting block 22, more than two first slide rails 1 made of metal are set on the ground, and the first slide The track route of the rail 1 is set according to the process layout of the factory. The first support 5 of the L-shaped structure arranged vertically is located above the first slide rail 1. The top of the first support 5 is provided with a frequency conversion motor 13 and a second rotating shaft 21. , th...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that the lower surface of the first bracket 5 is provided with more than four first pulleys 2 of the same size and structure that match the first slide rail 1 and replace it with the first bracket 5 The lower surface of the lower surface is provided with a first slideway that matches the first slide rail 1; the bottom of the second support 7 is provided with more than four second pulleys 4 of the same size and structure that match the second slide rail 3 The bottom of the second bracket 7 is provided with a second slideway matched with the second slide rail 3, so as to prevent the pulley from being too stressed and easily damaged, and the strip-shaped slideway can be evenly stressed.

Embodiment 3

[0033] The difference between this embodiment and Embodiment 1 is that a spray gun is provided on the spraying machine 19, and the spraying machine 19 is connected to the spraying gun through a conveying pipe, which is beneficial to the perfect place of mechanical spraying, and the manual repair of the spraying gun is used to achieve the best spraying. Effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com