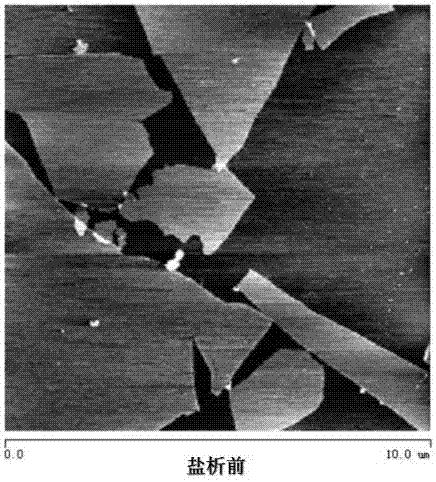

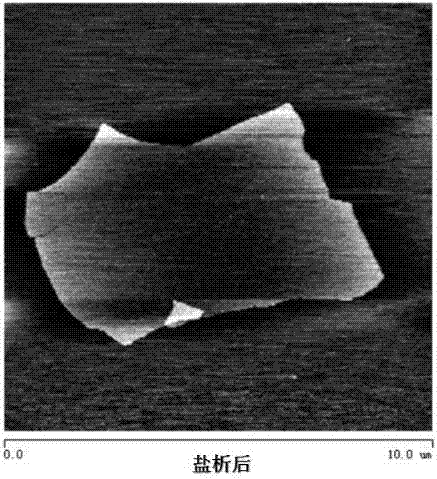

Preparation method of large-sized graphene oxide slice layer with high mechanical strength

A graphene sheet, mechanical strength technology, applied in graphene, chemical instruments and methods, inorganic chemistry and other directions, can solve the problems of complex operation, low mechanical strength of graphene oxide, long preparation period, etc., and achieves a simple preparation process, Good application prospect, short preparation cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A method for preparing a large-scale graphene oxide sheet with high mechanical strength, the steps are as follows:

[0017] (1). Add 2.5g potassium persulfate (K 2 S 2 o 8 ) and 2.5g phosphorus pentoxide (P 2 o 5 ), ultrasonication for 0.5h; then, 3g of natural graphite was added to the above dispersed solution at 78-82°C, stirred with a magnetic stirrer for 4.5h at a temperature of 80°C, cooled to room temperature, and deionized with 500ml Dilute with water and let it stand overnight; remove the supernatant, filter the precipitate with a 0.2mm filter, remove impurities, dry the precipitate in a vacuum oven at 60°C for 12 hours, and grind to obtain the pre-oxide after drying;

[0018] (2). Take out the above-mentioned dried pre-oxide, grind it into powder, then add it to 120ml of concentrated sulfuric acid and stir. The temperature in this process should be controlled at 5°C; take 15g of potassium permanganate (KMnO 4 ), grind it into powder, and then slowly add it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com