Low-energy consumption kitchen wastewater treatment process and equipment

A technology for kitchen waste water and treatment equipment, which is applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of increasing the complexity of system operation, complex operation, and water intake requirements High-level problems, to achieve the effect of being conducive to the reproduction of bacteria, low overall investment, and reducing sludge loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

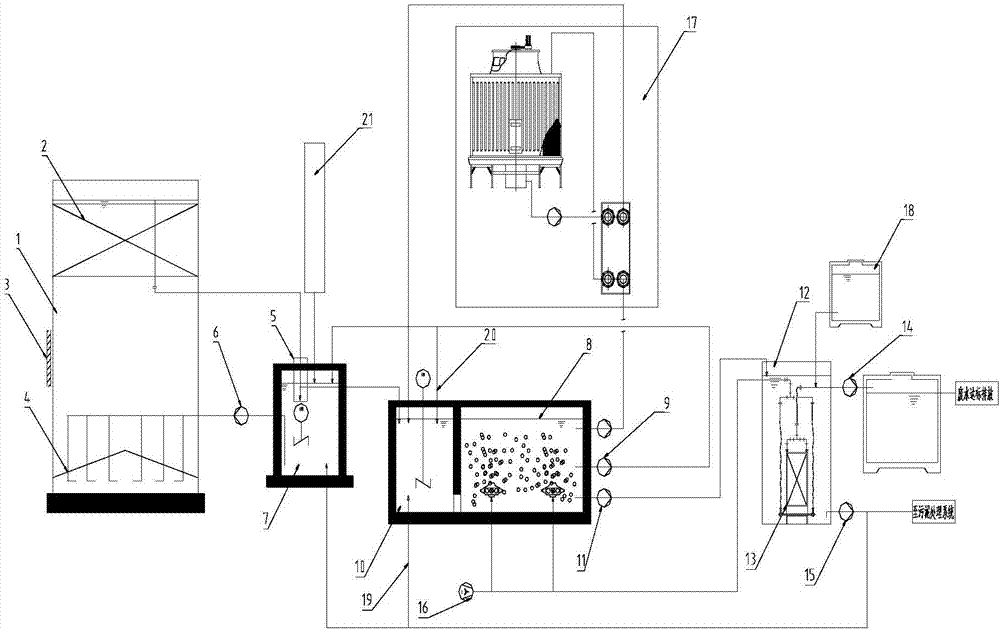

[0049] to combine figure 1 , which describes the first specific embodiment of the present invention in detail, but does not limit the claims of the present invention in any way.

[0050] like figure 1 As shown, the low-energy-consumption treatment equipment for kitchen wastewater in this embodiment includes a high-efficiency denitrification reactor 1, and a three-phase phase that realizes the three-phase separation of water, gas, and solid and prevents sludge loss is arranged on the top of the high-efficiency denitrification reactor 1. Separator 2, set water distributor 4 at the bottom of high-efficiency denitrification reactor 1, water distribution pool 7, aerobic pool 8, anoxic pool 10, cooling heat exchange system 17 connected to aerobic pool 8 and anoxic pool 10 respectively , cleaning pool 18,

[0051] It also includes a water distributor 5, which is arranged on the top of the water distribution tank 7, receives the water output from the high-efficiency denitrification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com